Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

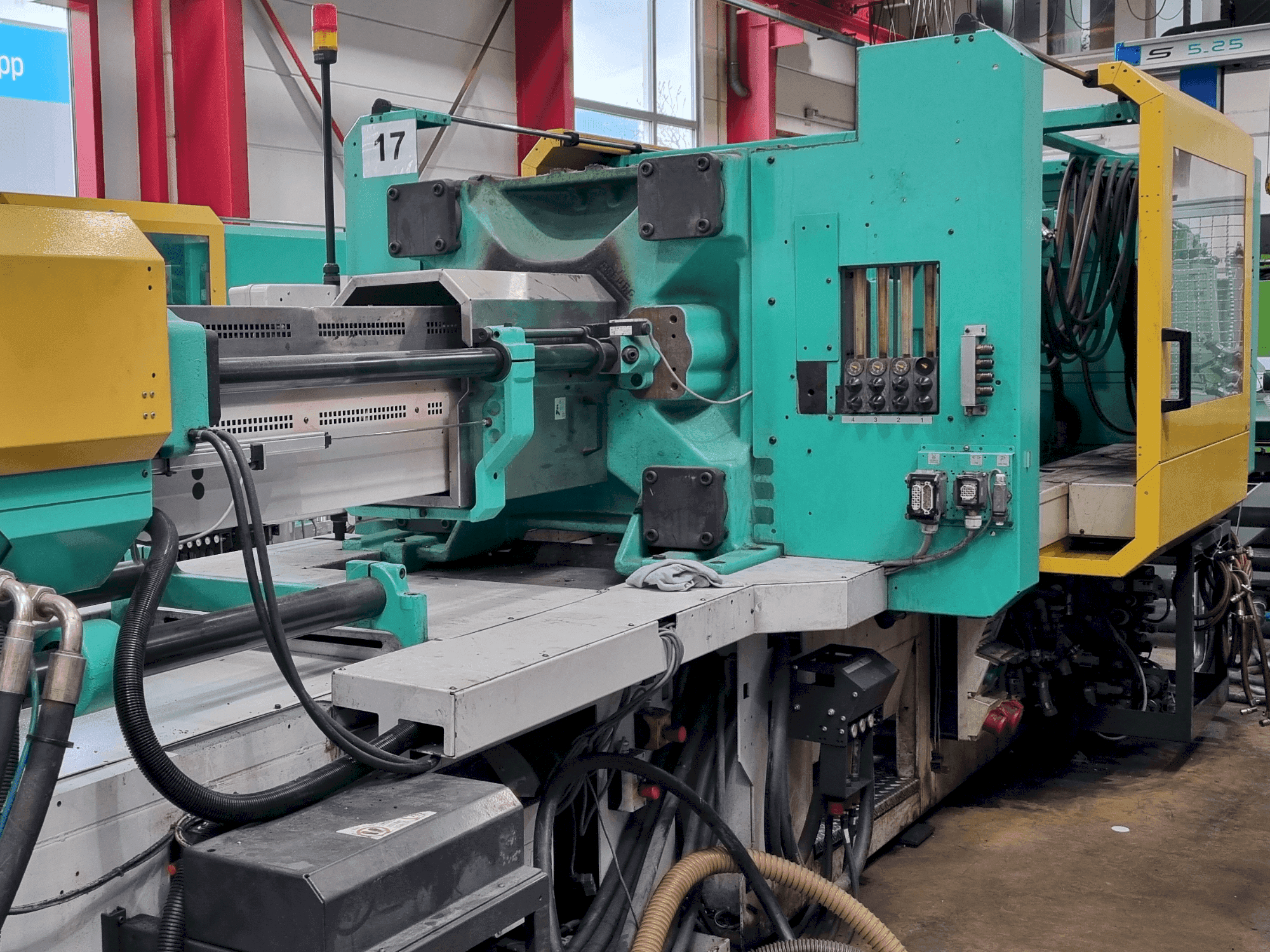

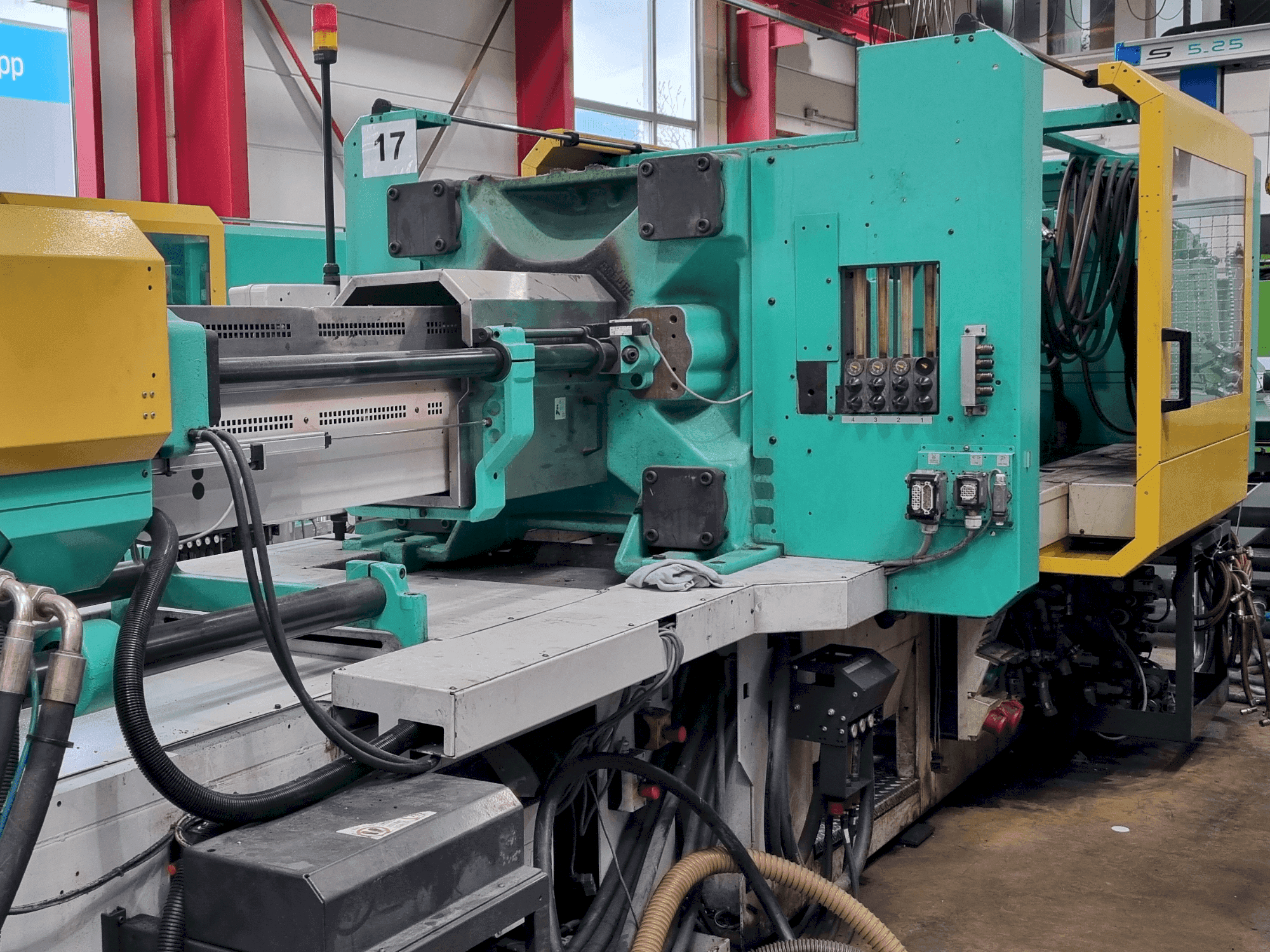

Arburg - 630 S 2500-1300 ECODE-INJ-ARB-2006-00010

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Plastics Processing Machinery

- ➤ Used Arburg 630 S 2500-1300 ECO For Sale | gindumac.com

This Arburg 630 S 2500-1300 ECO was manufactured in 2006. It features a robust hydraulic system with two servo-controlled pumps for precise machine movements and programmable mold clamping force. The plasticizing cylinder is suitable for abrasive or high-temperature materials. Equipped with SELOGICA control for efficient operation and comprehensive process monitoring. Consider the opportunity to buy this Arburg 630 S 2500-1300 ECO hydraulic injection moulding machine. Contact us for more information about this machine.

Overview

- brand: Arburg

- year: 2006

- MODEL: 630 S 2500-1300 ECO

- application type: Injection Moulding

- Location: Germany

- machine type: Hydraulic Injection Moulding Machine

Technical Information - Arburg 630 S 2500-1300 ECO

Technical Specification

- Clamping Force: 2500 kN

Additional Information

Additional equipment

- Equipment includes a pneumatic needle valve nozzle with electrical preparation, quick-release coupling for ejector, and motorized ejector plate technology. Mold monitoring and a hydraulic quick-lock system are provided, with four cooling circuits per clamping plate.

Extra Information

Injection Unit Control parameters include injection flow/speed, hold pressure, and nozzle feed. Injection pressure can increase by approximately 10%, with a maximum of 2500 bar. The injection unit features a 60mm plasticizing cylinder assembly suitable for handling thermoplastics with abrasive or corrosive components. Control & Operation The SELOGICA control system is modular with a graphic, multi-processor system. It features a TFT color flat screen and automatic mold height adjustment. Quality Assurance & Process Monitoring Quality assurance includes comprehensive equipment for process graphics, error messages, alarm cycles, and performance evaluation, with options for documentation and value logging.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing

Products related to Arburg 630 S 2500-1300 ECO

CJ480M3V

CHENDE - Hydraulic Injection Moulding Machine

Allrounder 920H 5000-4600

Arburg - Hydraulic Injection Moulding Machine

S 6000-5500E

Netstal - Hydraulic Injection Moulding Machine

VM 150/750V R1520 UNIGLOG B6S

Battenfeld - Hydraulic Injection Moulding Machine

ROBOSHOT S 100 iA

FANUC - Electrical Injection Moulding Machine

Roboshot S150iA

FANUC - Electrical Injection Moulding Machine

ELEKTRA 180

FERROMATIK - Electrical Injection Moulding Machine

El-Exis S 250/630-1450

SUMITOMO SHI DEMAG - Hydraulic Injection Moulding Machine

ROBOSHOT S-2000 i 150B

FANUC - Electrical Injection Moulding Machine

Elion 800-270

Netstal - Hydraulic Injection Moulding Machine

520 H 1500-400

Arburg - Hydraulic Injection Moulding Machine

470 H 1000-170

Arburg - Hydraulic Injection Moulding Machine