Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

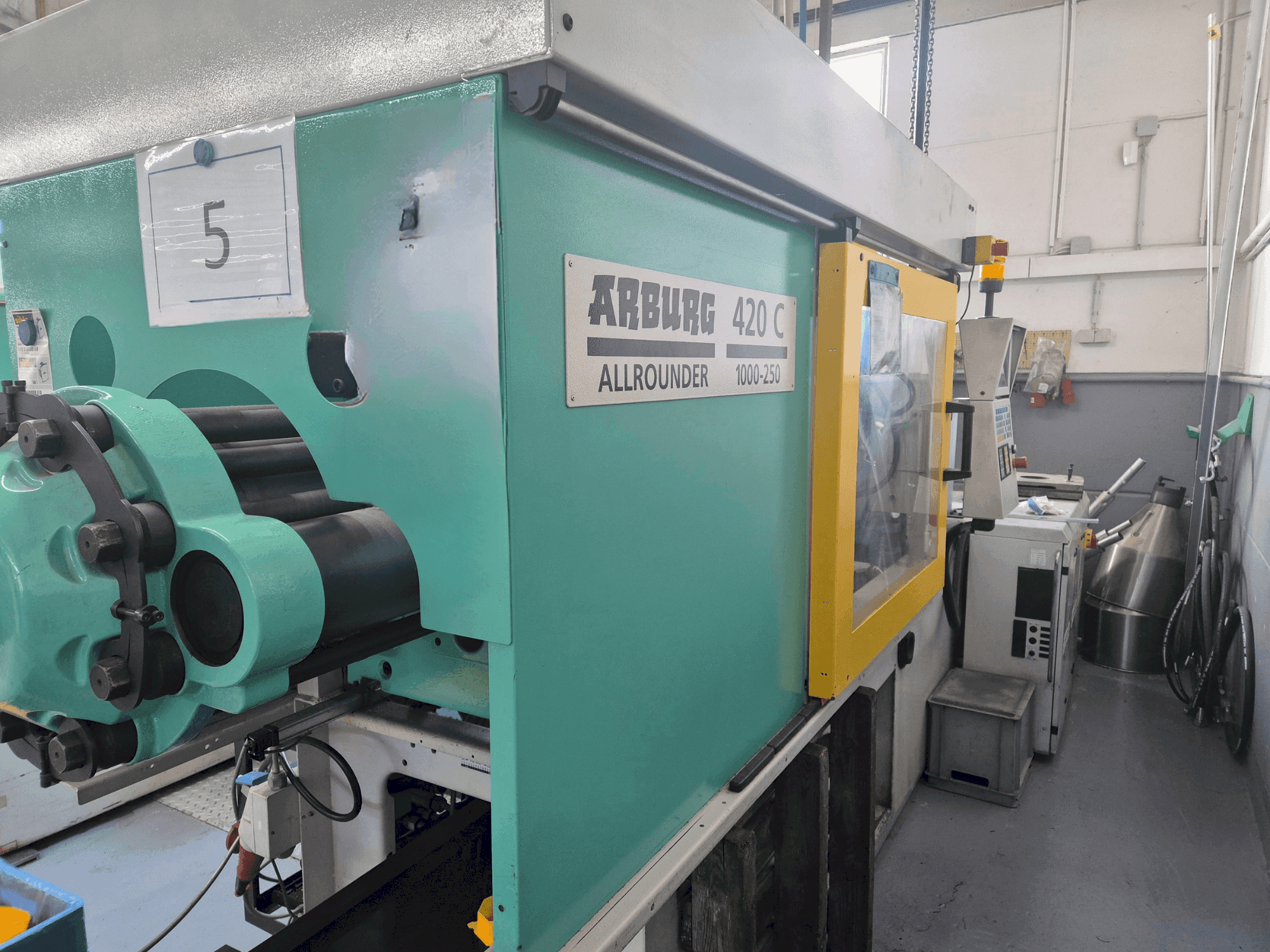

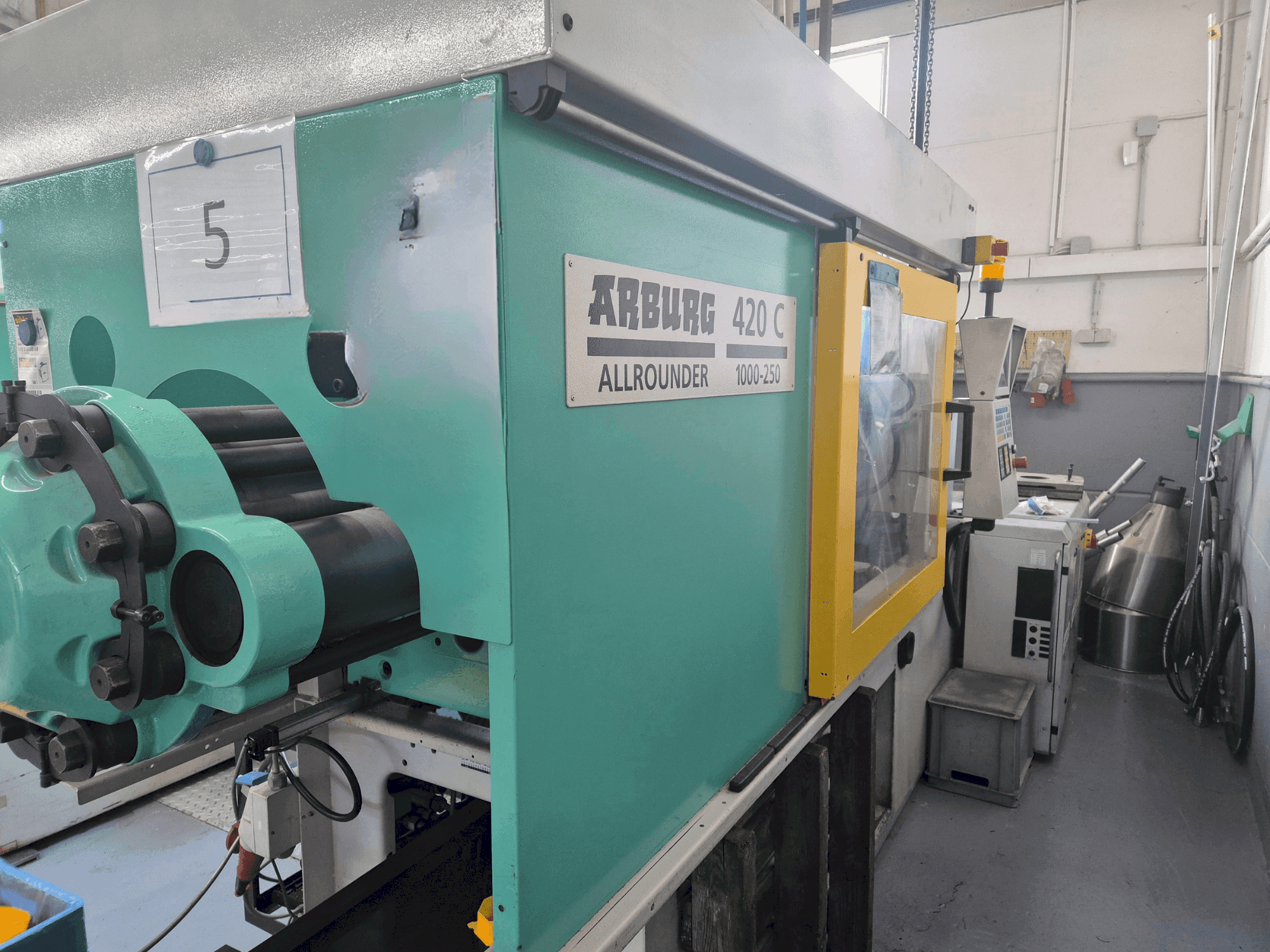

Arburg - Allrounder 420 C 1000-250DE-INJ-ARB-1999-00005

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Plastics Processing Machinery

- ➤ Used Arburg Allrounder 420 C 1000-250 For Sale

This Arburg Allrounder 420 C 1000-250 was manufactured in 1999. It is a hydraulic injection moulding machine, ideal for precision plastic processing. Consider the opportunity to buy this Arburg Allrounder 420 C 1000-250 hydraulic injection moulding machine. Contact us for further details regarding this machine.

Overview

- brand: Arburg

- year: 1999

- MODEL: Allrounder 420 C 1000-250

- production hours: 116061

- application type: Injection Moulding

- Location: Germany

- machine type: Hydraulic Injection Moulding Machine

Additional Information

Machine Benefits

Technical Machine Benefits

- Clamping force: 1000 kn

- Cylinder diameter: 40 mm / injection weight max. Ps: 158 g / injection volume: 150 ccm / nozzle radius: r40

- Mould height at least: 250 mm / opening stroke: 500 mm /distance between tie bars: 420 mm /centring ring: 125 mm /bakra clamping system: yes

Extra Information

Clamping unit Clamping force (max.): 1000 kN Closing force (max.): 50 kN Opening force / increased (max.): 35/250 kN Opening stroke (max.): 500 mm Mould installation height (min.): 250 mm Distance between the mould mounting platens (max.): 750 mm Clear column distance: 420x420 mm Mould mounting platens (w x h): 570x570 mm Weight of moving mould half / with support (max.): 600 kg Ejector force (max.): 40 kN Ejector travel (max.): 175 mm Hydraulics, drive, other Drive power of the hydraulic pump: 18.5 kW Total installed power: 26.6 kW Colour: Plastic coating structure light grey / mint green Switch cabinet: Safety regulation: DIN EN 60204 Schuko socket outlet: 1 x 10 A Cekon socket outlet: 1 x 16 A Injection unit Screw diameter: 30/35/40 mm Effective screw length L/D: 23.3/20/17.5 Screw stroke (max.): 150 mm Calculated stroke volume (max.): 106/144/188 cm³ Injection weight (max.): 89/121/158 g/hp Injection pressure (max.): 2470/1820/1390 bar Injection flow (max.): 144/196/256 cm³/s Injection flow with accumulator (max.): 350/476/622 cm³/s Back pressure positive / negative (max.): 350/140 bar Screw peripheral speed (max.): 47/57/66 m/min Screw torque (max.): 420/490/560 Nm Nozzle contact force (max.): 70 kN Nozzle lift-off distance (max.): 240 mm Installed barrel heating: 1600+3x1300 W Installed nozzle heating: 600 W Granulate container capacity: 50 litres Horizontal injection position (max.): 170 mm Machine dimensions and weights Oil filling: 230 litres Net weight: 3180 kg Electrical connection (pre-fuse): 100 A

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing