Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

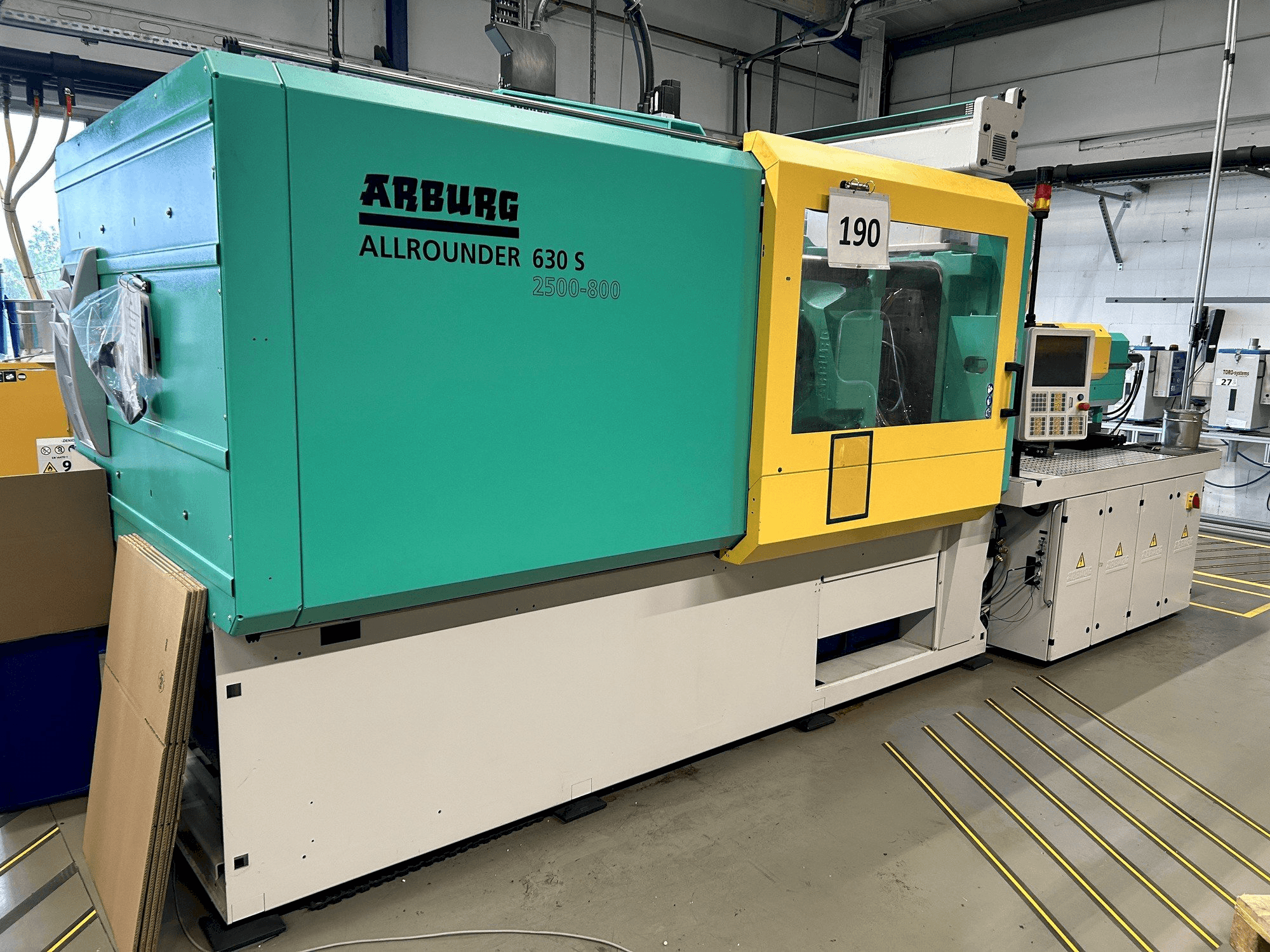

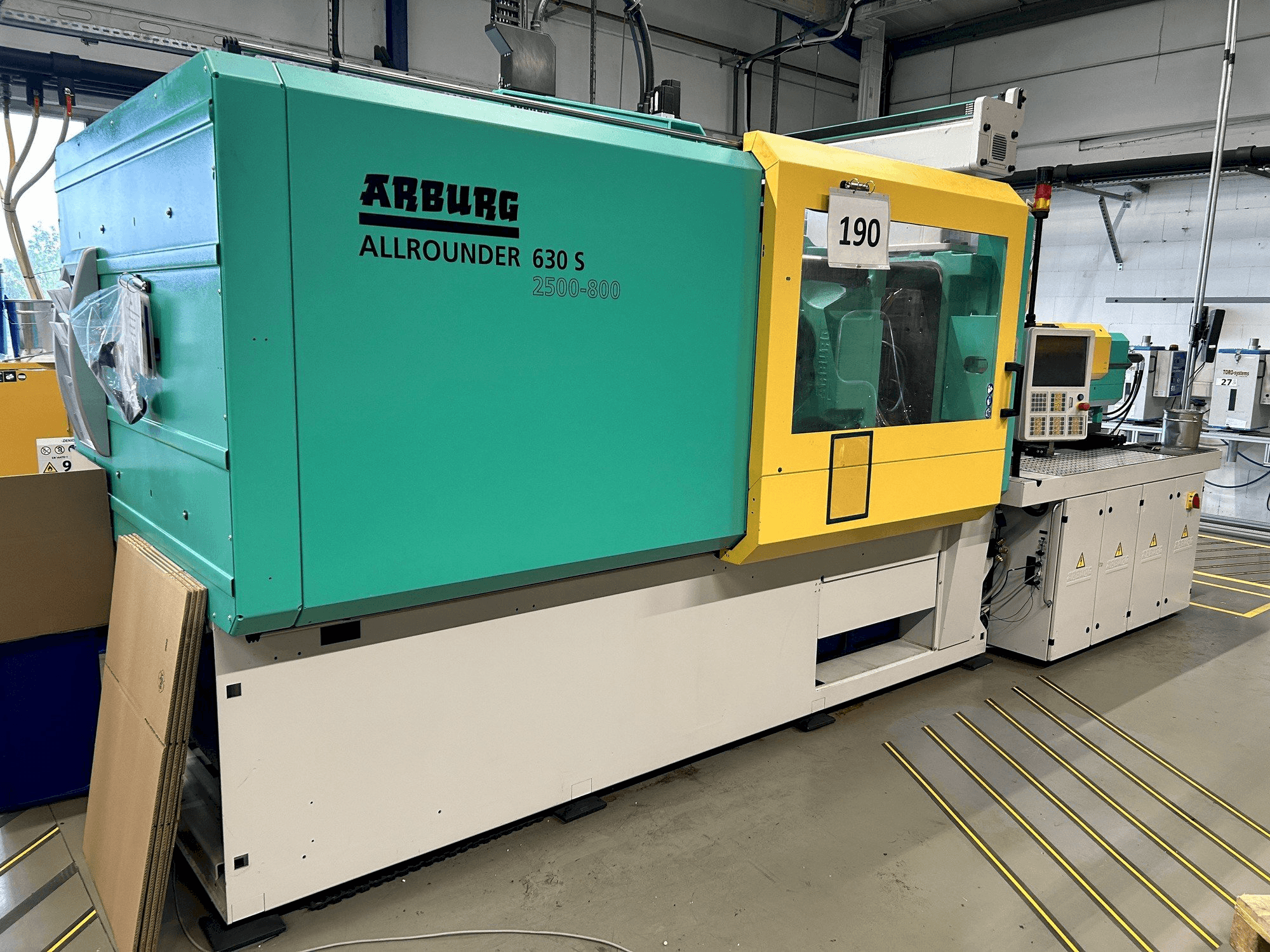

Arburg - Allrounder 630S 2500-800DE-INJ-ARB-2016-00002

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Plastics Processing Machinery

- Used Injection Moulding Machine Arburg Allrounder 630S 2500-800 - 2016 - for sale | gindumac.com

This ARBURG Allrounder 630S 2500-800 injection moulding machine was manufactured in May 2016. It offers a robust 2750kN clamping force, with a hydraulic drive system and precise control features, including 18 hot runner control zones. Key specifications include 45mm screw diameter, a 318cm³ dosing volume, 2470 bar maximum injection pressure, and a 242 cm³/s injection speed, ensuring high performance and consistent quality in production. Furthermore, it's equipped with a Multilift Select robotic system, enhancing automation and efficiency in handling. The ARBURG Allrounder machine we have for sale is tailored for high-volume and intricate moulding operations. It is in very good condition, and has low hours (only 4507 automatic hours) as it was mainly used as technical center machine for sampling and tryouts. Contact us for more information about this injection moulding machine. See original order confirmation (German) for further details attached below.

Overview

- brand: Arburg

- year: 2016

- MODEL: Allrounder 630S 2500-800

- production hours: 4507

- application type: Injection Moulding

- Location: Germany

- machine type: Hydraulic Injection Moulding Machine

- control unit brand: ARBURG

Technical Information - Arburg Allrounder 630S 2500-800

Control Unit

- Control Brand: ARBURG

- Control Model: Selogica

Technical Specification

- Clamping Force: 2500 kN

- Max. Shot Weight: 291 g

- Screw Diameter: 45 mm

Additional Information

Additional equipment

- Robot system: Arburg Multilift Select with Payload: 15 kg, 3-CNC axes (X=2000/Y=700/Z=1000) + C-axis (O° / 90°, 24 Nm), and integration

- Extended mold installation height via adjustment plate

- Interface for communication with Kistler CoMo Injection

- Conveyor belt

- Safety fence for Multilift operation

Machine Benefits

Qualitative Machine Benefits

- Integrated robot system (arburg multilift select) for efficient handling and production automation

- It is in very good condition, and has low hours (only 4507 automatic hours)

- Mainly used as technical center machine for sampling and tryouts

Technical Machine Benefits

- Number of core pulls (hydraulically controlled): 6

- Number of hot runner control zones: 18

Extra Information

Machine cycles: 338114 // Operating hours pump: 7868 // Operating hours automatic: 4507 // Operating hours semi-automatic: 570 // Operating hours robot system: 2315

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Documents

Borja Garcia

Payment Terms

Payment in advance

Asset Financing