Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

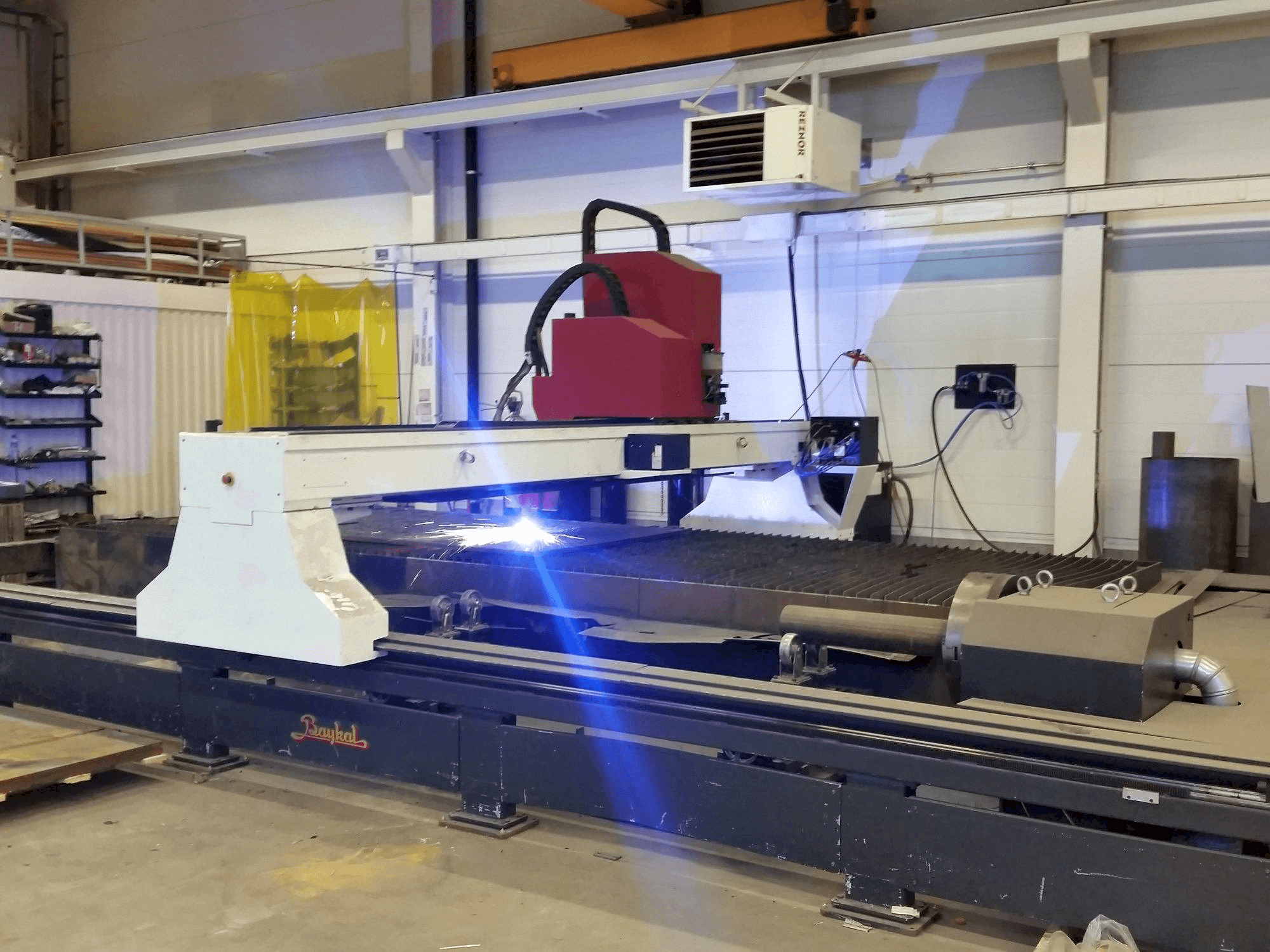

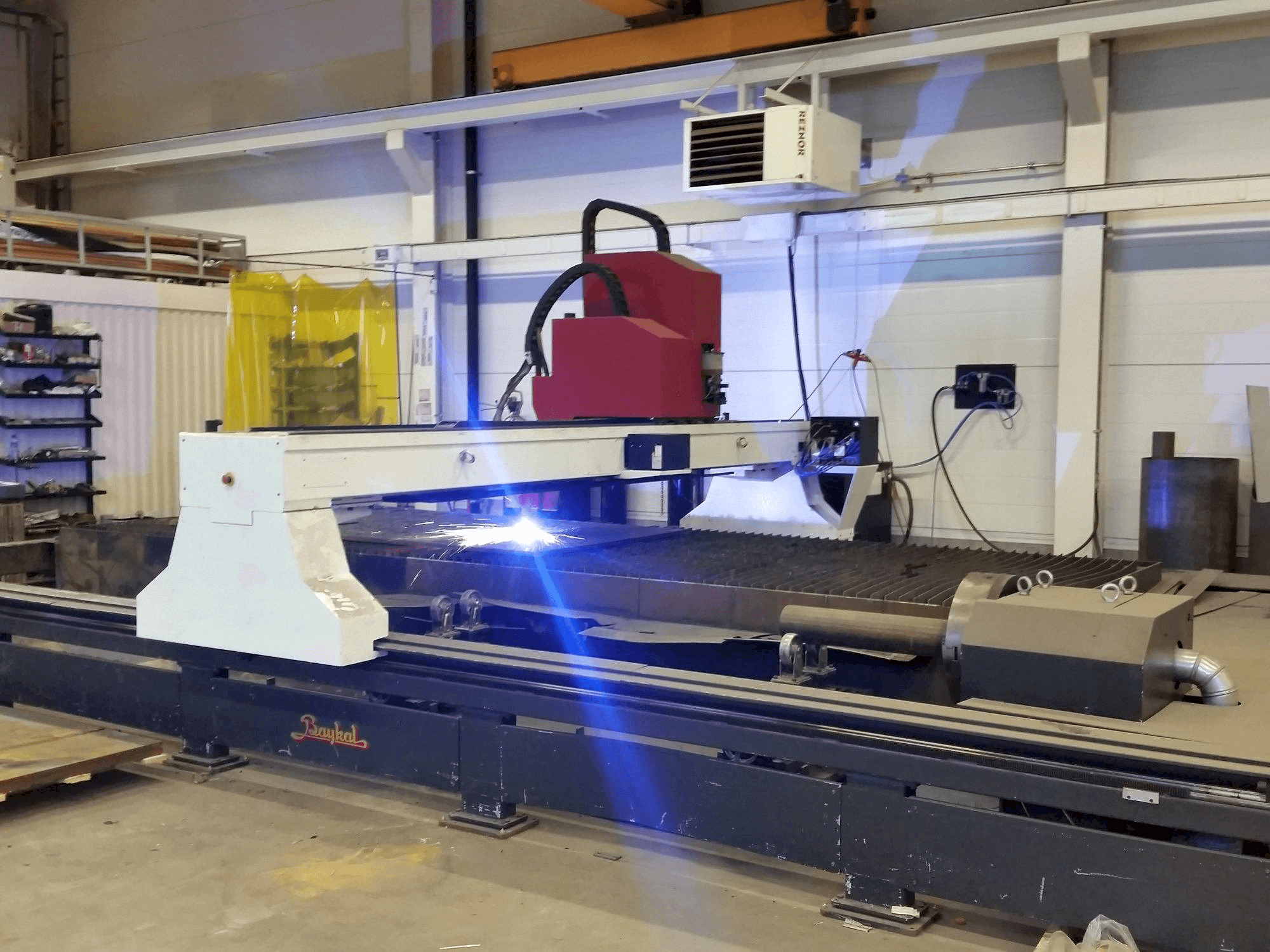

Baykal - BPL-H 2006 HPR 260XDNO-PLA-BAY-2015-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Sheet Metal Machinery

- Baykal BPL-H 2006 HPR 260XD Plasma Cutting Machine

This Baykal BPL-H 2006 HPR 260XD Plasma Cutting Machine was manufactured in the year 2015. It is equipped with a Technos PC12 control unit. The machine has a positioning speed of Up to 20 000 mm/min.

Overview

- brand: Baykal

- year: 2015

- MODEL: BPL-H 2006 HPR 260XD

- application type: Cutting

- Location: Norway

- machine type: Plasma Cutting Machine

Technical Information - Baykal BPL-H 2006 HPR 260XD

Dimensions

- Table Length: 6400 mm

- Table Width: 2200 mm

Additional Information

Machine Benefits

Qualitative Machine Benefits

- The cutting table is independently constructed from the cross beam and machine frame, to achieve positioning accuracy under any weight on the table.

- The cutting head has sensors for automatic adjustment of the cutting head cutting height.

- Collision protection on the plasma cutting head, the machine comes with electrical equipment for: 400v

- Sectioned cutting table integrated with automatic extraction system, extraction hatches that open on the work surface for better extraction, plasma cutting head : including cable pull chain

- "high-definition type plasma supply unit, programming software for nesting/optimization of parts via pc, regulator : single output

- Manual/automatic gas console for selection of plasma and additive gases, high capacity air filter unit for dust and fume collection (optional), hose package : hose package for cutting source, gas supply : hose package for gas supply

- One set of consumables (nozzles, electrode, nozzle holder, manifolds etc), positioning speed : up to 20 000 mm/min

- Working temperature : between -10° c to +30° c, exhaust system : cnc operated with pneumatic hatches, motorsy axes : left and right side two brushless ac servomotors, traverse y axes : double-sided via rack and pinion drive, motor x axis : brushless ac servo motor, transverse x axis : via rack and pinion and gear drive

- Operation y axis : double-sided, two-way longitudinal operation, operation x axis : double-sided transverse operation, guide y axis : linear guides, guide x axis : linear guide, guide x axis : linear guide

- Plasma source : hypertherm hydefinition plasma hpr260xd with, auto gas console, control : technos pc12 ( made in the usa ) windows based, software package : lantek nesting software for pc ( lantek expert ii )

Technical Machine Benefits

- Pipe cutting function Ø50-600mm

- Bevel head

- 6-station drill and thread unit, drill max Ø20mm, thread max Ø16mm

- Stationary control panel instead of panel on cutting boom, positioned on the left side of the machine when viewed from the front.

- Cutting width : 2200mm

- Cutting length : 6400mm

- Double-sided synchronized servo drive on y axis = longitudinal movement of cutting head

- Single synchronized servo drive on x axis = transverse movement of cutting head

- Ac servo driven motors (brushless)

- Fast positioning speed 20 mt/min with ± 0. 05 mm positioning accuracy

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing

Products related to Baykal BPL-H 2006 HPR 260XD

ER 4000

ERMAKSAN - Plasma Cutting Machine

Speedy 360

Trotec - CO2 Laser Cutting Machine

FL 600 3D

TTM - Tube Cutting Machine

MERCURY 603 1520 350W

SEI - CO2 Laser Cutting Machine

Speedy 360

Trotec - Laser Engraving Machine

TruLaser 1030

TRUMPF - CO2 Laser Cutting Machine

ByAutonom 3015

Bystronic - CO2 Laser Cutting Machine

MSF 9001.25Lr+T500 (2015)

MicroStep - Fiber Laser Cutting Machine

Spark 20040

GASPARINI - Plasma Cutting Machine

TRUMATIC L3030

TRUMPF - CO2 Laser Cutting Machine

TruLaser 3030

TRUMPF - CO2 Laser Cutting Machine

APHS 41600

Baykal - Press Brake