Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

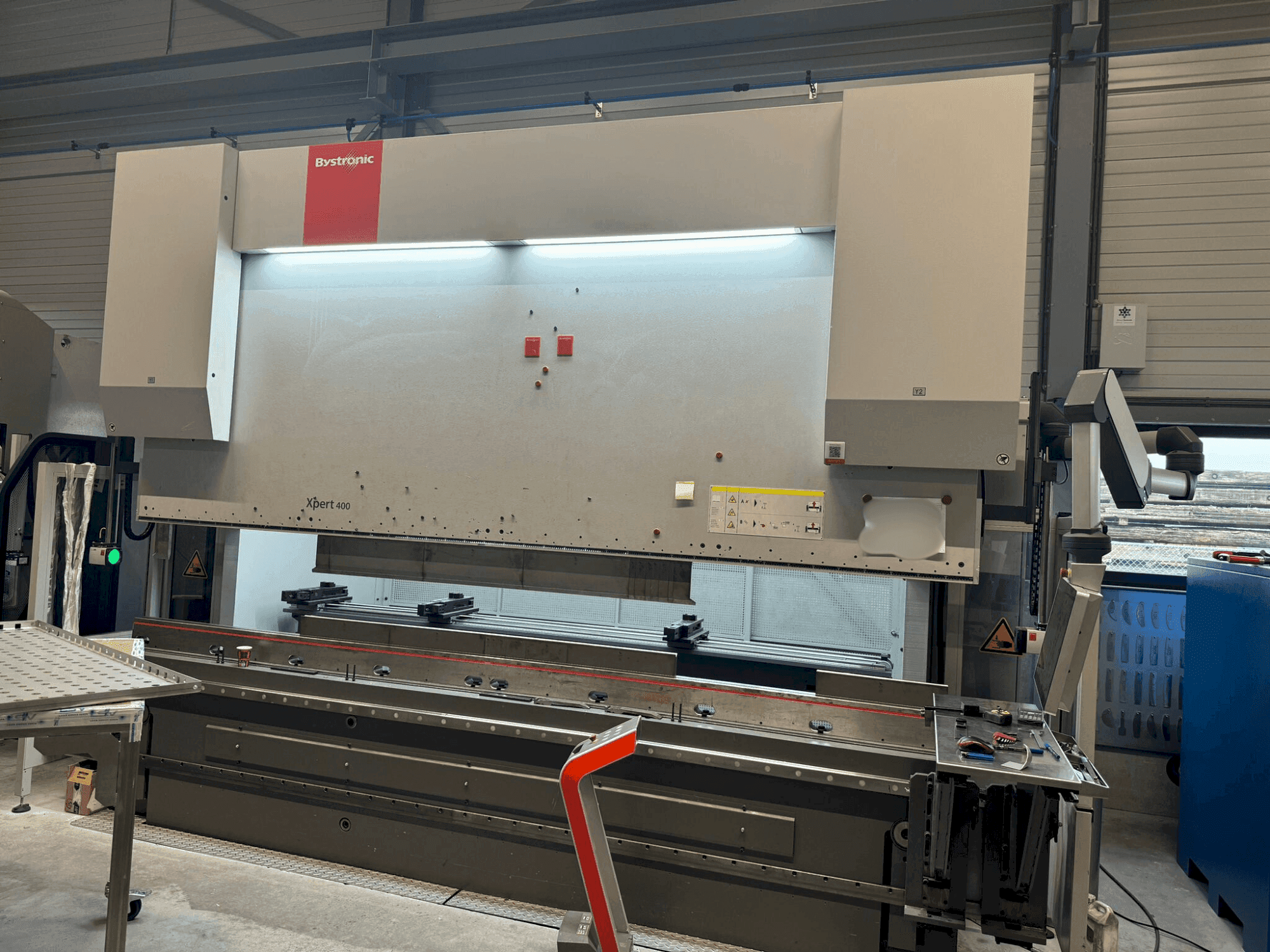

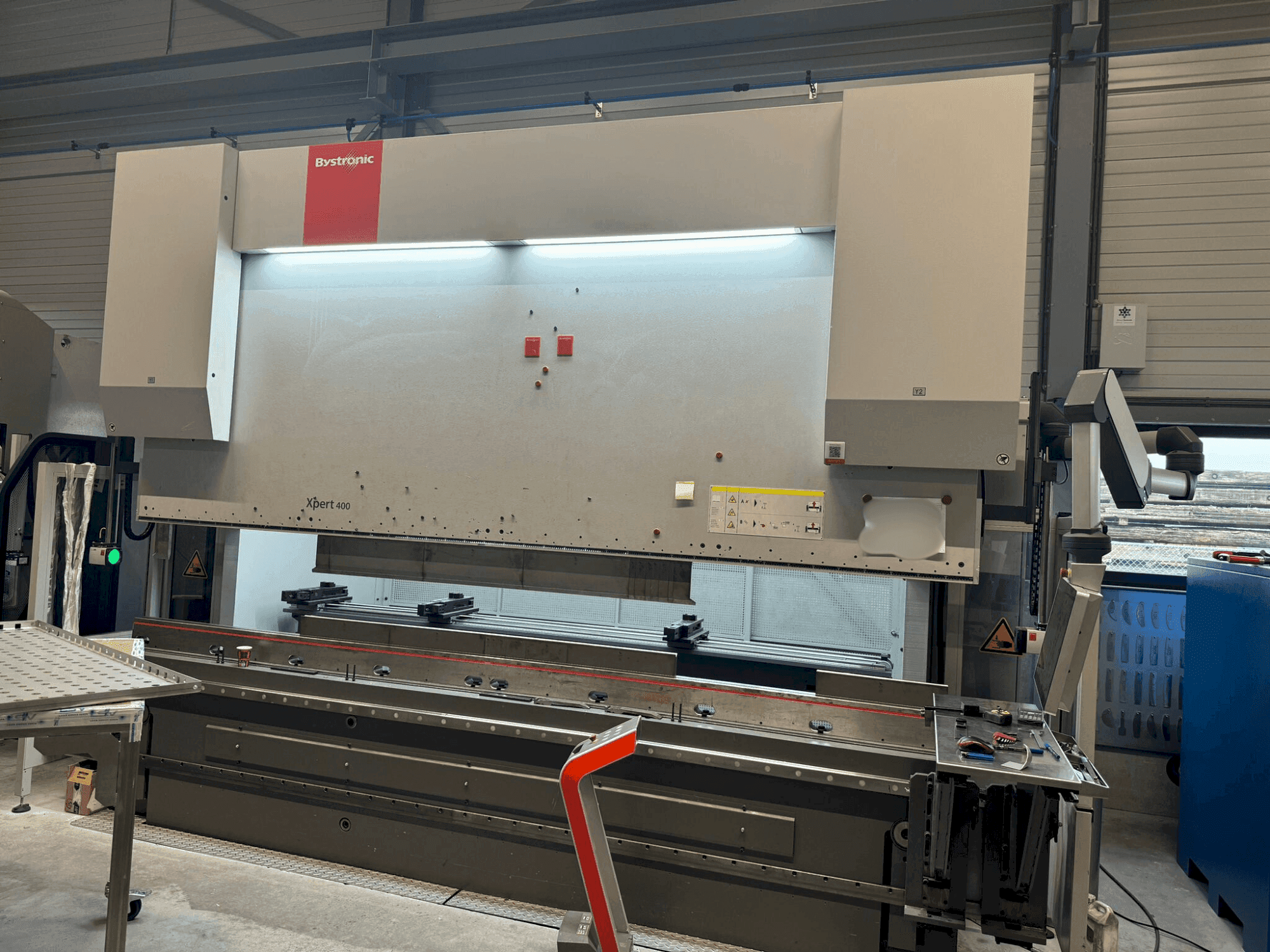

Bystronic - Xpert 400/4100NL-BEN-BYS-2017-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Sheet Metal Machinery

- ➤ Used Bystronic Xpert 400/4100 For Sale | gindumac.com

This 6-axis Bystronic Xpert 400/4100 press brake was manufactured in 2017. It offers precision bending with enhanced control and flexibility. Ideal for complex metal forming, this machine represents a significant asset for any fabrication setting. Contact us for more information about this machine.

Overview

- brand: Bystronic

- year: 2017

- MODEL: Xpert 400/4100

- application type: Bending

- Location: Netherlands

- machine type: Press Brake

Technical Information - Bystronic Xpert 400/4100

Dimensions

- Machine Depth: 4880 mm

- Machine Height: 3230 mm

- Machine Weight: 28300 kg

Movement

- Number of Axes: 6

Additional Information

Additional equipment

- ByVision Bending operator terminal with 22 inch Full HD touchscreen

- OPC Interface Bending

- Bending curve generator

- Automatic kickstand suspension compensation by means of dynamic pressure reference

- Crown 4: Reactive hydraulically dynamic crowning of the lower cheek

- Automatic tool overload protection

- Compensation of the temperature-induced stator expansion

- Automatic dynamic pressure control with crowning 4

- Material thickness measurement

- Fast Bend - safety system manually adjustable in height

Machine Benefits

Qualitative Machine Benefits

- Upper tool clamping type rf-a hydraulic

- Hardened weld plates at the top of the tool clamp

- Machine has 4 axes back gauge x, r, z1, z2. The other 2 are for pulling up and pressing down the upper beam with y1 and y2.

- Additional backgauge finger in z-direction, manually movable, finger height = 40 mm (20/20)

Technical Machine Benefits

- The r-axis method (for 2/4/5 axes) has a range of 250 mm, a maximum speed of 150 mm/s, and an accuracy of 0. 1 mm.

- The z-axis has a range of 2900 mm, with a maximum speed of 1000 mm/s for 4/5 axes, 800 mm/s for 6 axes, and 1890 mm/min as an alternate speed for 6 axes, with an accuracy of 0. 1 mm for 4/5 axes.

- Table width: 60 mm

- 2 x manually adjustable front workpiece support in reinforced design, support bracket louvre 1000 mm (> 320t)

- Scale on the upper cheek

- Side guards with electrical monitoring

- Rear safety gate with sliding door with electrical monitoring

- Linear guide with two parking spaces of 250 mm each

- Double guide of the upper cheek

- Installation heights and stroke increase by 100 mm

Extra Information

Machine still under power

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing