Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

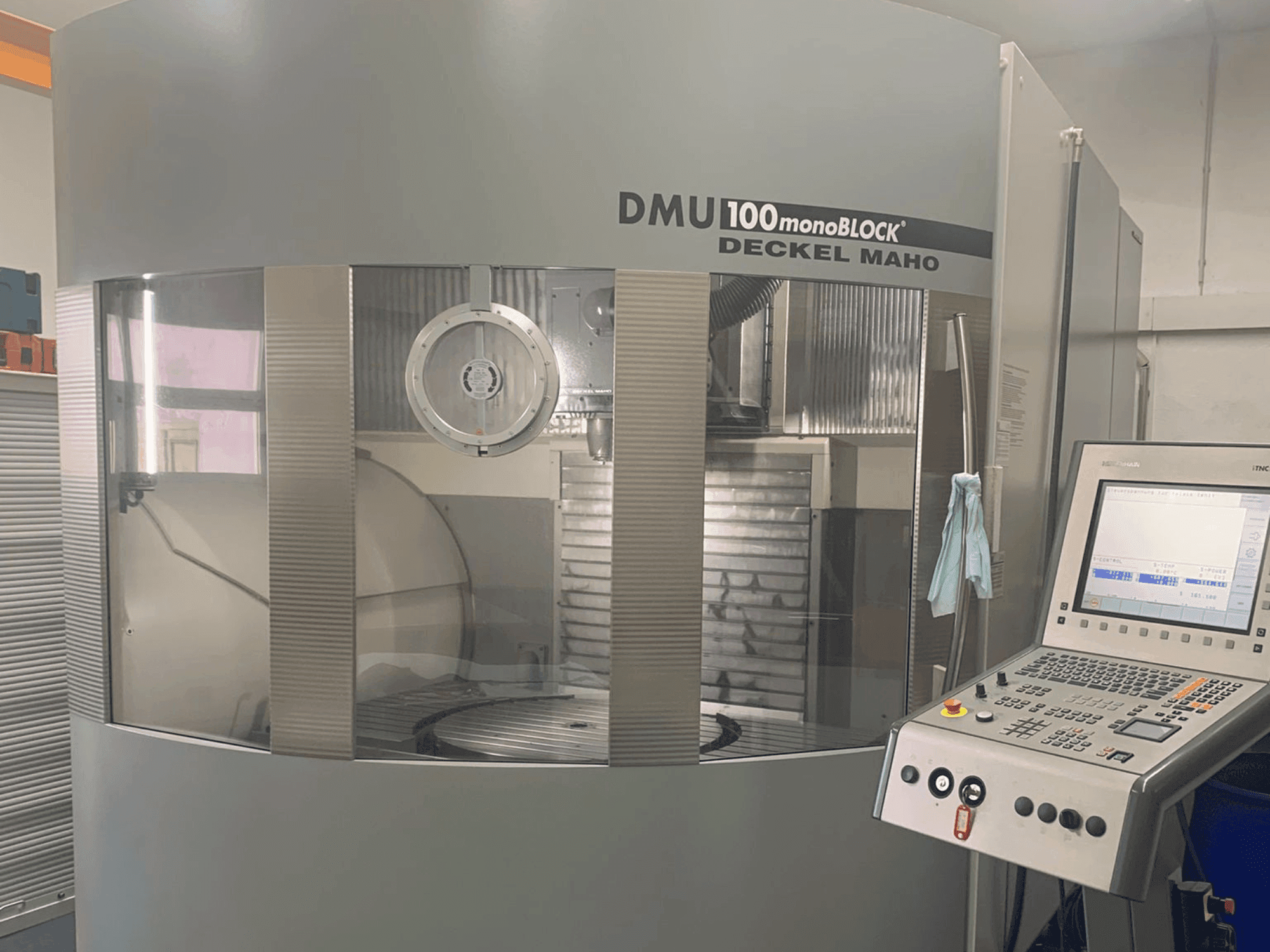

DMG - DECKEL MAHO 100T MonoblockDE-MIL-DMG-2005-00003

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used DMG DECKEL MAHO 100T Monoblock | Machining Center

This 5-axis DMG DECKEL MAHO 100T Monoblock was manufactured in 2005. It features a motor spindle speed of 12,000 rpm, a power of 15 kW, and a tool holder SK 40. The machine includes a manual swivel milling head, a pick-up system with 32 magazine positions, and an NC rotary table with an 800 mm diameter. If you are looking to get high-quality milling capabilities, consider the DMG DECKEL MAHO 100T Monoblock machine we have for sale. Contact us for more information.

Overview

- brand: DMG

- year: 2005

- MODEL: DECKEL MAHO 100T Monoblock

- production hours: 5000

- application type: Milling

- Location: Germany

- machine type: Vertical Machining Centre

- control unit brand: HEIDENHAIN

Technical Information - DMG DECKEL MAHO 100T Monoblock

Control Unit

- Control Brand: HEIDENHAIN

- Control Model: iTNC530

Movement

- Number of Axes: 5

- X-axis Travel: 710 mm

- Y-axis Travel: 710 mm

- Z-axis Travel: 1250 mm

Technical Specification

- Spindle Power: 10 kW

- Spindle Speed: 12000 RPM

- Taper Size: SK 40

Additional Information

Machine Benefits

Technical Machine Benefits

- Tool changer: pick-up system with 32 magazine positions, sk 40

- The machine comes with a lot of equipment.

Extra Information

Table Fixed Table: 1500 mm x 800 mm T-slots: 1x Guide Slot: 14 H7 (center) 10x Chip Slots: 14 H12 T-slot Spacing: 63 mm Permissible Table Load: 800 kg NC Rotary Table (Integrated): Diameter: 800 mm Length: 1500 mm Additional Equipment Milling Head: Manual swivel milling head Optional: Controlled NC swivel milling head (B-axis) with hydraulic clamping Spindle Offset: 100 mm Swivel Range: -120° / +30° X-axis travel range reduced by 100 mm Measuring Probe & Control: Measuring Probe: Heidenhain TS 641 (infrared) Control: Heidenhain iTNC 530 with electronic handwheel Operating Mode 4: "Process Monitoring in Production" Chip and Coolant Management: Chip Conveyor Internal Cooling through Spindle Center (AD form) Production Package: 40 bar / 23 l/min (theoretical pump capacity) Tank: 600 l Paper Belt Filter Rotating Viewing Window Chip Flushing Integrated in Work Door Flushing Gun with Pump: 1 bar / 40 l/min Cooling Device for Blown Air through Spindle Center, Selectable via M Function

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing