Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

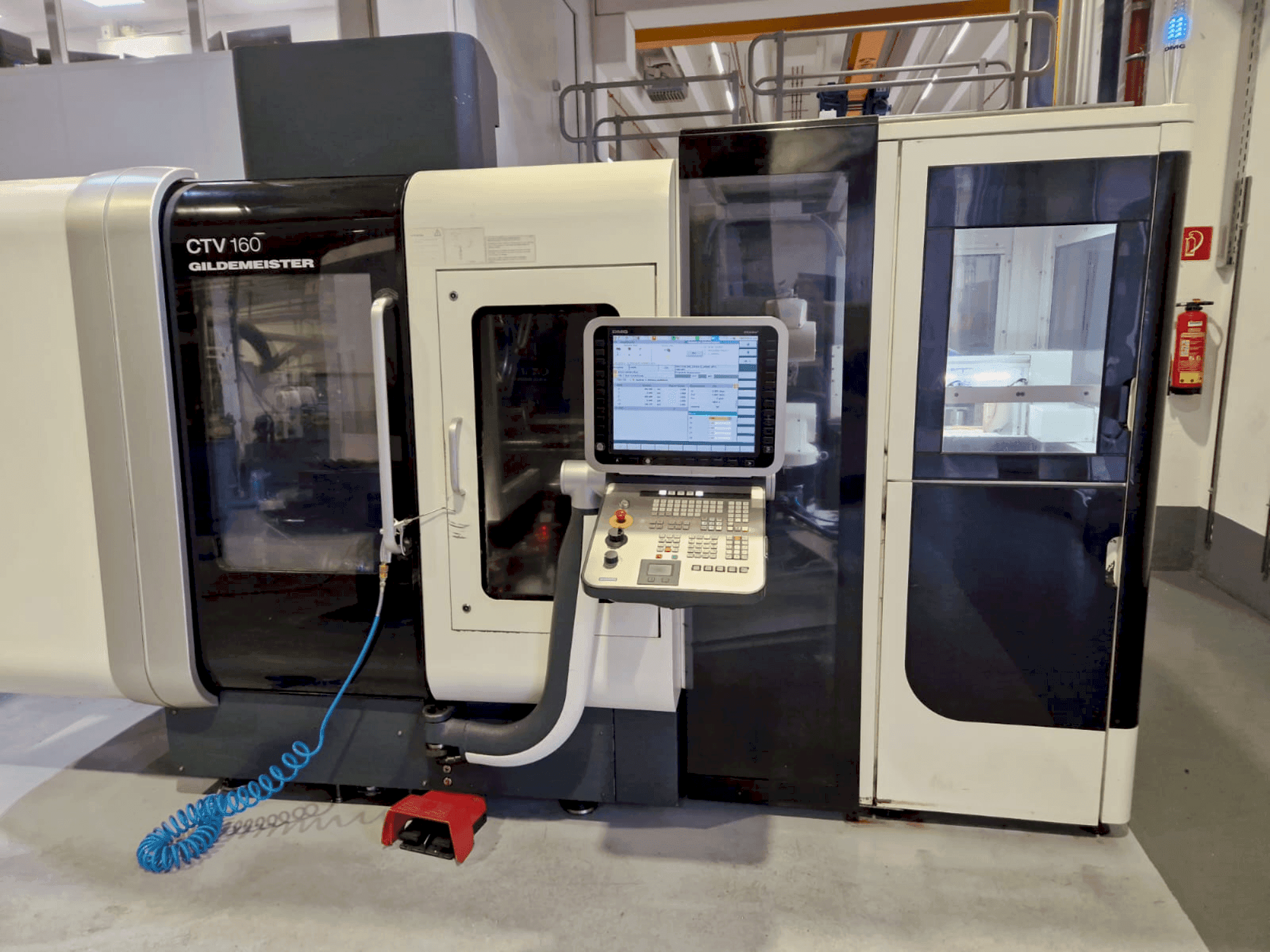

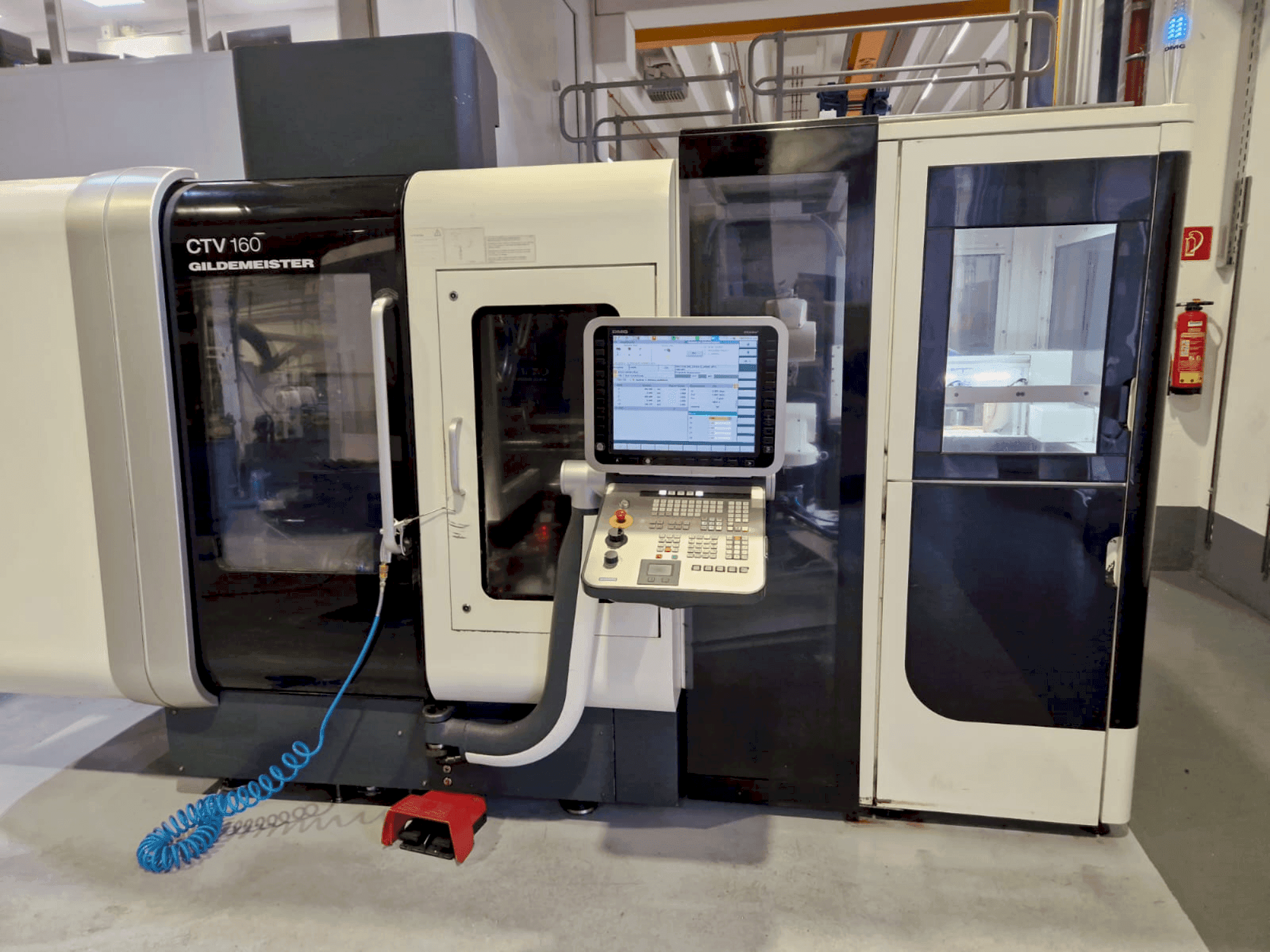

DMG - Gildemeister CTV 160DE-TUR-DMG-2010-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used DMG Gildemeister CTV 160 For Sale | gindumac.com

This 4-axis DMG Gildemeister CTV 160 vertical turning machine was manufactured in 2010. It features a Siemens Sinumerik 840D ERGOline control system, a 12-station tool turret, and a Schunk ROTA THW PLUS 165-43 power chuck. The machine includes a KUKA KR5 sixx R850 robot with a 3-finger centric gripper and a camera system for part recognition. Ideal for high-precision tasks, the DMG Gildemeister CTV 160 machine we have for sale. Contact us for more information.

Overview

- brand: DMG

- year: 2010

- MODEL: Gildemeister CTV 160

- application type: Turning

- Location: Germany

- machine type: Vertical Turning Machine

- control unit brand: SIEMENS

Technical Information - DMG Gildemeister CTV 160

Control Unit

- Control Brand: SIEMENS

- Control Model: Sinumerik 840D ERGOline

Technical Specification

- Spindle Power: 16 kW

- Spindle Speed: 6000 RPM

Additional Information

Additional equipment

- Machine with one work area and additional parts storage incl. robot

- Tool turret with 12 stations, shank diameter Ø30mm, DIN 69880, all positions driven

- Full clamping cylinder SMW SIN-S-85-LPS-X

- 3-jaw wedge bar power chuck with quick jaw change system, ROTA THW PLUS 165-43 from Schunk

- ARTIS tool breakage monitoring system, type CTM

- Coolant system with belt filter system 40µm, delivery volume 20 / 40 l/min, at 8 / 20 bar respectively, coolant tank volume approx. 600 litres

- Chip conveyor hinged belt design with integrated cooling lubricant tank capacity approx. 120 litres, chip discharge height 1100mm

- Integrated oil mist extraction 400m³/h

- 15-fold pallet circulation system for max. workpiece dimensions of Ø115x60mm, incl. KUKA KR5 sixx R850 robot with 3-finger centric gripper for max. 5.3kg and a gripper turning station

- Camera system for part recognition

Machine Benefits

Qualitative Machine Benefits

- Torque at 100% ed: 135 nm (main drive), 13 nm (tool carrier)

- Torque at 40% ed: 176 nm (main drive), 18 nm (tool carrier)

- Spindle head din 6353 size 140h5

- Max. Actuating force fv at 70 bar: 34 kn

Technical Machine Benefits

- Torque: 135 nm (100% ed), 176 nm (40% ed)

- Max. Workpiece diameter: Ø115 mm / max. Workpiece length: 60 mm

- High-performance main drive and tool carrier

- Quick jaw change system for the 3-jaw power chuck

- Integrated cooling and chip management systems

- Artis tool breakage monitoring system

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing