Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

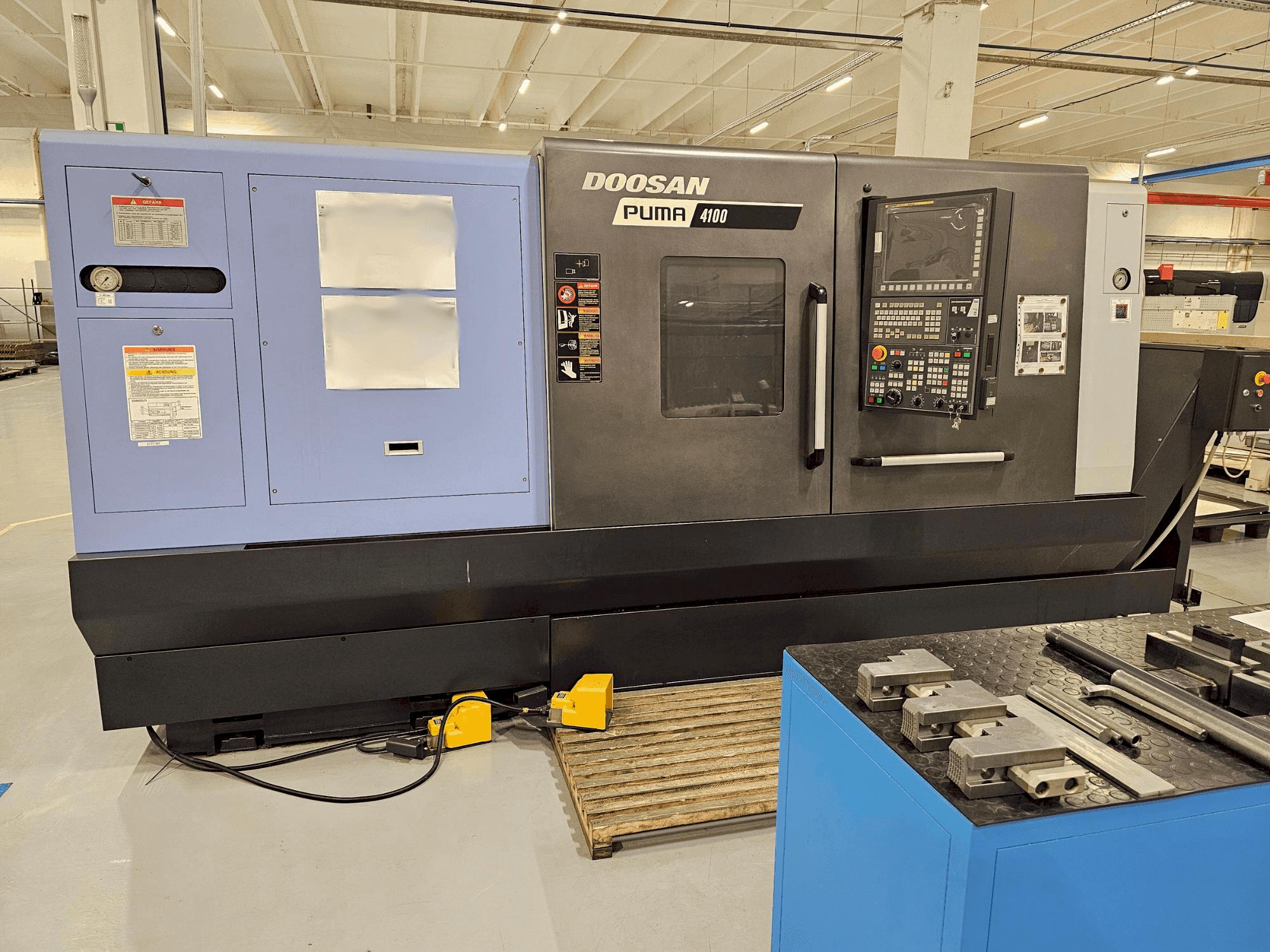

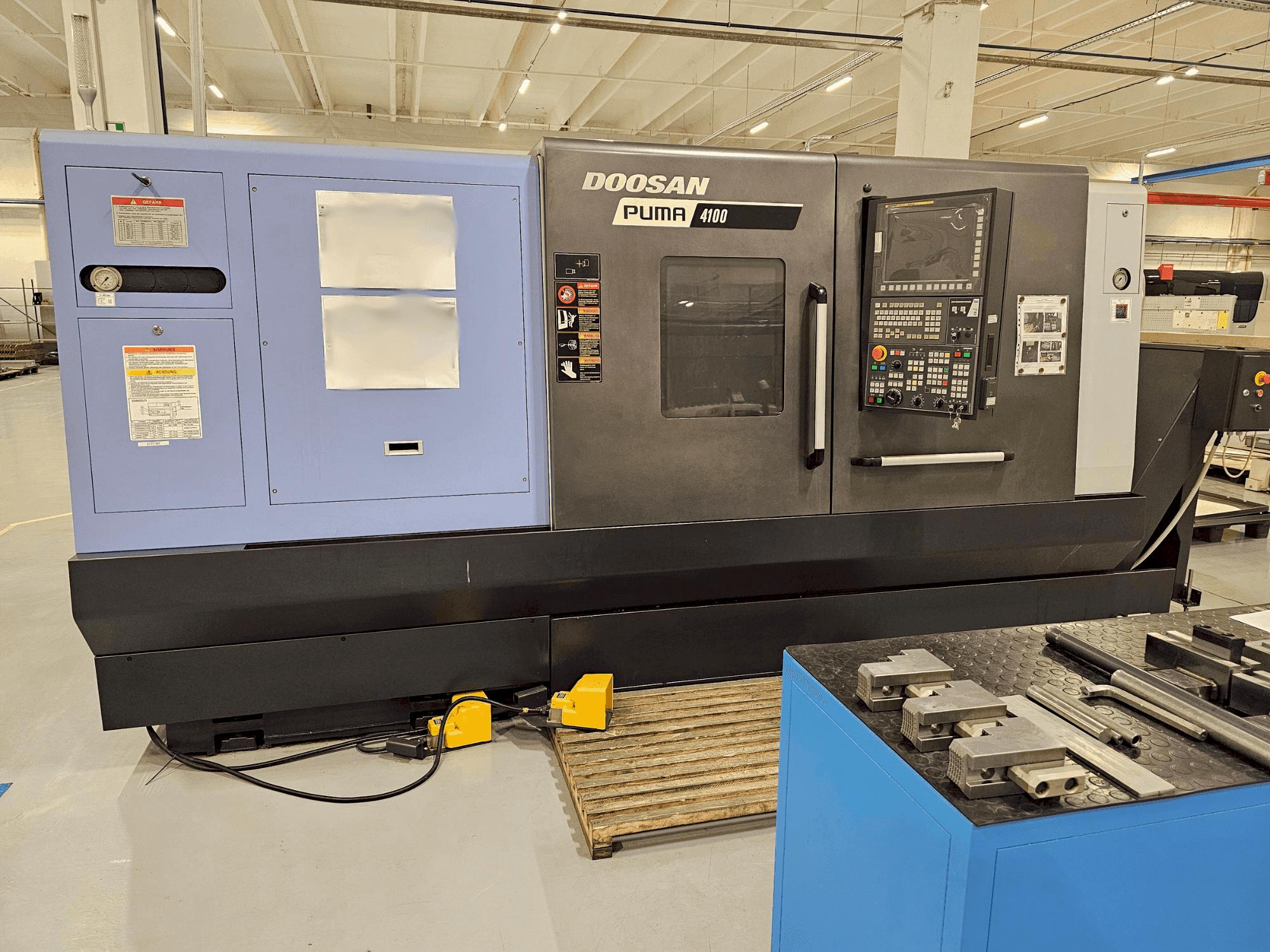

DOOSAN - PUMA 4100BBG-TUR-DOO-2018-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- Used Horizontal Lathe DOOSAN Puma 4100B - 2018 - for sale | GINDUMAC.COM

This DOOSAN Puma 4100B Horizontal Lathe was manufactured in 2018 in South Korea. It is equipped with a maximum workpiece diameter of 550 mm and a maximum workpiece length of 1042 mm. Controlled by a FANUC 0i Series control, it offers a spindle speed of 2000 rpm with a spindle power of 35 kW (30 min) / 22 kW (continuous). This machine accommodates 10 tools and features a A2-11 ASA taper size, providing versatility and precision in machining operations. It comes with chip conveyor, hydraulic, lubrication and cooling system. The machine has a run time of 796 hours, is still under power and can be inspected at any time.

Overview

- brand: DOOSAN

- year: 2018

- MODEL: PUMA 4100B

- production hours: 796

- application type: Turning

- Location: Bulgaria

- machine type: Horizontal Turning Machine

- control unit brand: FANUC

Technical Information - DOOSAN PUMA 4100B

Control Unit

- Control Brand: FANUC

- Control Model: 0i Series

Dimensions

- Machine Depth: 2056 mm

- Machine Height: 2194 mm

- Machine Weight: 9950 kg

Movement

- X-axis Travel: 352 mm

- Z-axis Travel: 1105 mm

Technical Specification

- Spindle Power: 35 kW

- Spindle Speed: 2000 RPM

Additional Information

Additional equipment

- Hydraulic system // Tank capacity: 16 L, Viscosity grade of oil: ISO VG32

- Lubrication system // Tank capacity: 4.3 L, Discharge volume: 0,1 (50Hz) L/min, Viscosity grade of oil: ISO VG68

- Coolant system // Tank capacity: 365 L, Coolant oil type: Water soluble cutting fluid, Coolant pump motor power: 0.4 kW, Coolant pump max. pressure: 0,15/0,1 (60/50Hz) MPa, Coolant pump max. flow rate: 40 L/min

- Full enclosure chip and coolant shield

- Front door interlock Foot switch

- Hydraulic power unit

- Hydraulic chuck & actuating cylinde

- Work light

- Chip conveyor

Machine Benefits

Qualitative Machine Benefits

- Tool holder & boring sleeve kit

- Easy operating system

- Doosan ez guide i

- Programmable tail stock

- Coolant pump 4 kw 1,0 mpa 30l/min

- Tool setter automatic

- Signal tower

- Oil skimmer

- Doosan tool load monitoring

- Arbitrary speed threading hardened & ground hard jaws

Technical Machine Benefits

- Swing over bed: 790mm // swing over saddle: 590mm

- Max turning diameter: 550mm

- Max turning length: 1042mm

- Bar working diameter: 116. 5mm

- Accuracy: positioning x, z: 0,01/0,02mm

- Repeatability: ±0,002 / ±0,003

- Drive mechanism - belt drive + gear box standard chuck size: 380(15”) mm // spindle nose: a2-11 asa // spindle bearing diameter (front): Ø180 mm // spindle through hole diameter: Ø132 mm // bore of draw tube: Ø117. 5 mm

- Max. Spindle torque for turning: 2379 n. M

- Tail stock - drive mechanism: programmable (drive bar + carriage) // quill diameter: Ø120 mm // quill travel: 120 mm // tail stock travel: 1000 mm // tail stock center: #5 dead center mt

- Turret - tool holder mount type: di base holder // number of tool stations: 10 ea // turret indexing type: servo driven type // turret indexing time – full station: 1. 9 // od tool size: 32x32 mm // max. Boring bar size: Ø60 mm // rapid traverse rate x, z - axis: 16/20 m/min // ballscrew (diameter x lead) – x axis: 40 x 8 mm // ballscrew (diameter x lead) – z axis: 50 x 10 mm // servo motor power x, , z – axis: 4,0 / 7,0 kw

Extra Information

Control power: 3Ph-AC220V/50Hz // Required power capacity: 42.25 kVA // Compressed air supply, pressure: 0.5 MPa // Display unit size 15” color // 380V – 220V Electric power transformer

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing