Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

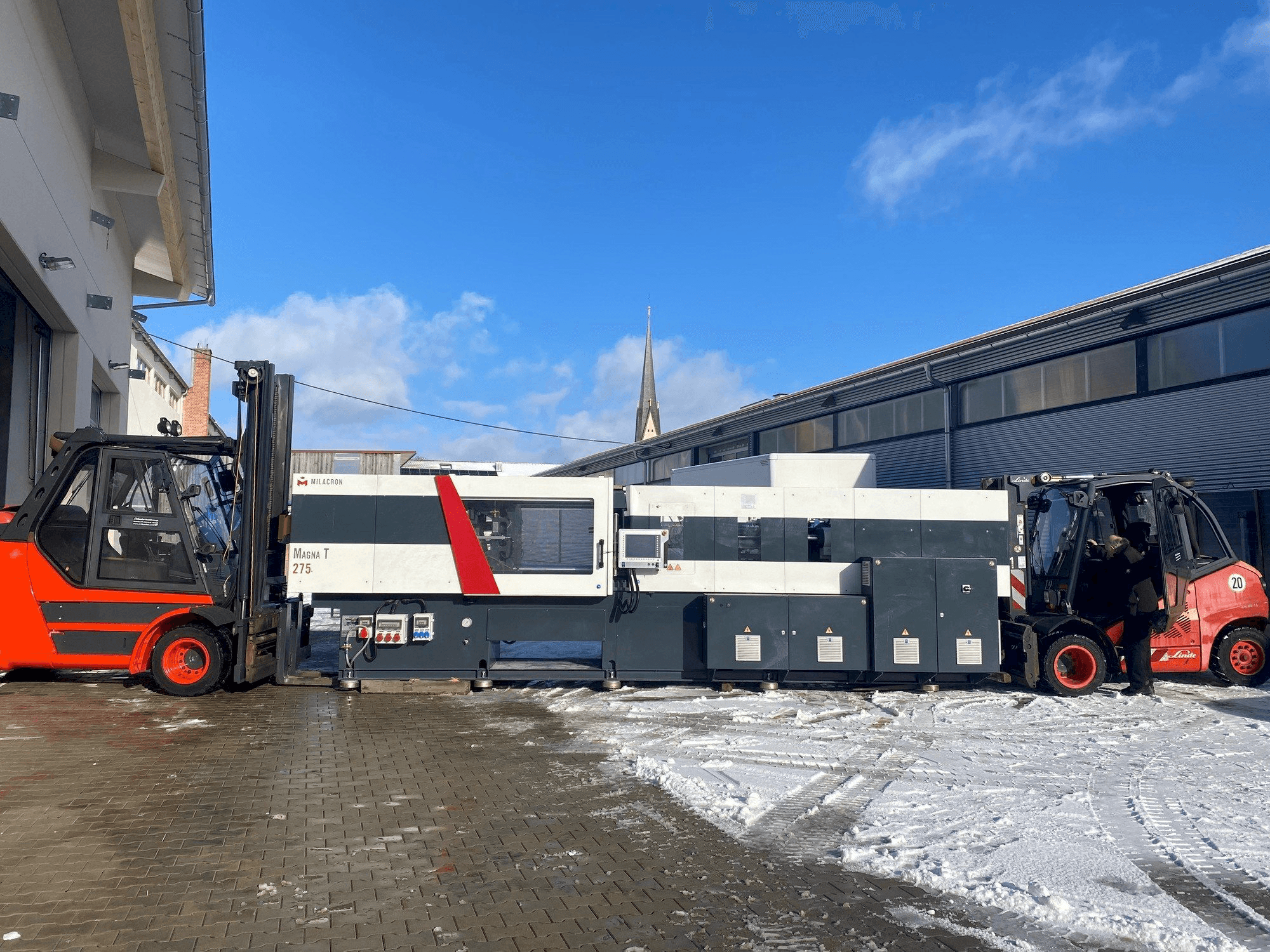

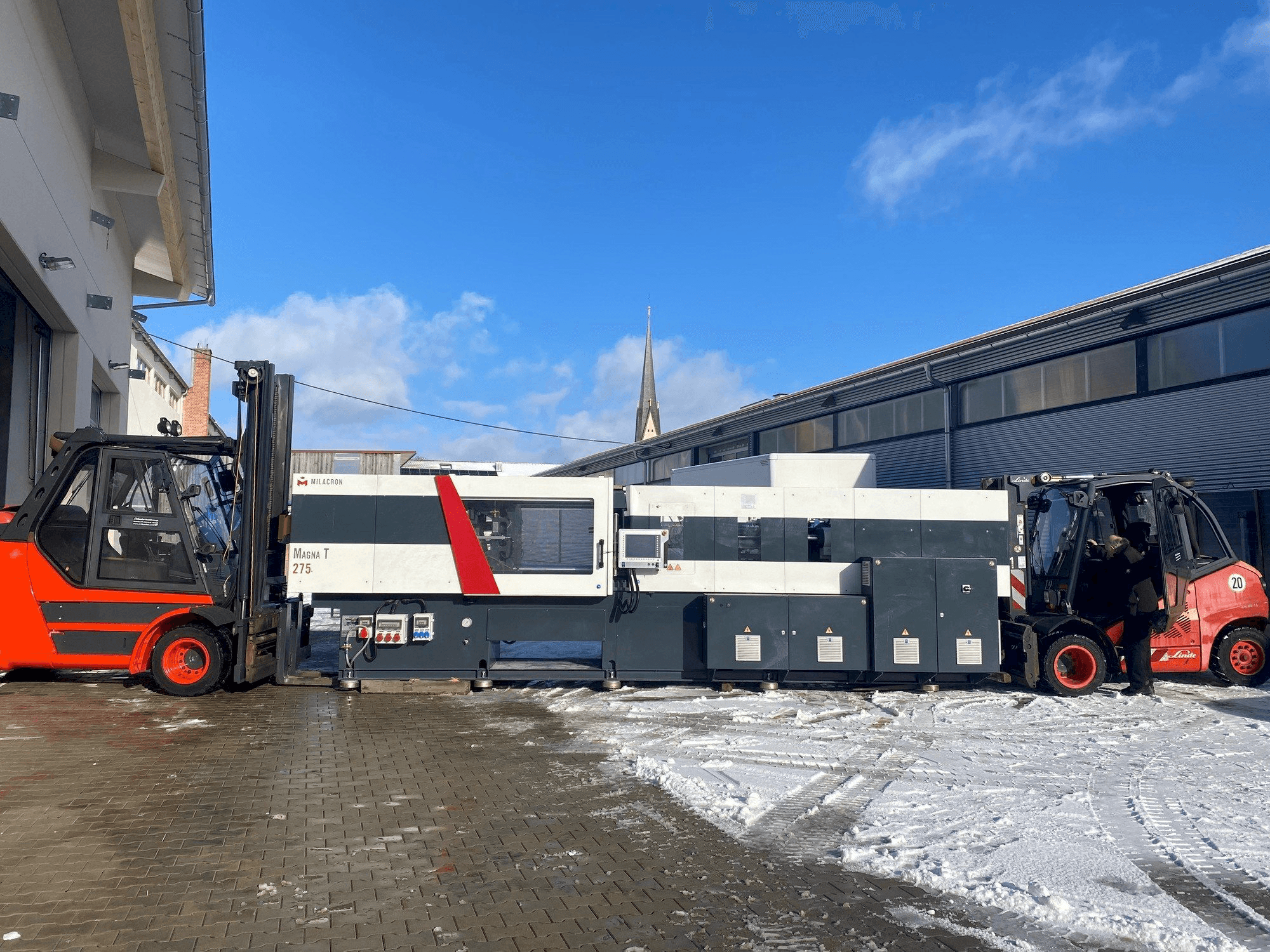

FERROMATIK - Magna T (MTs) - 275DE-INJ-FER-2018-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Plastics Processing Machinery

- Ferromatik Milacron Magna T (MTs) - 275 Injection Moulding Machine

This FERROMATIK Magna T (MTs) - 275 Injection Moulding Machine was made in the year 2018. It has a clamping force of 2750 kN and a column spacing of 660 x 660 mm. Max. plate distance is 1560 mm and mould installation height 400 - 950 mm. The opening stroke is at 610 mm. This injection moulding machine is equipped with a ENDURA touch control and a 1540 injection unit with 50mm screw diameter. It comes with 2x hydraulic core pullers (2-fold). See full original tech specs as PDF (DE) attached. Automation solution can be purchased additionally upon request.

Overview

- brand: FERROMATIK

- year: 2018

- MODEL: Magna T (MTs) - 275

- application type: Injection Moulding

- Location: Germany

- machine type: Hydraulic Injection Moulding Machine

Technical Information - FERROMATIK Magna T (MTs) - 275

Dimensions

- Machine Weight: 14680 kg

Technical Specification

- Clamping Force: 2750 kN

- Screw Diameter: 50 mm

Additional Information

Machine Benefits

Qualitative Machine Benefits

- Ejector or core pull can be moved in parallel via closing movement via separate pump

- Control system siemens s7 / kuka

- Injection unit 1540 / screw diameter 50mm / standard 3-zone screws aps

- Bimetallic screw cylinder type x 102 / hydraulic core pull 2-fold / cooling water battery with 10 control circuits

- Sar automation: dimensions 6000 x 5000 x 3000 mm

- Provision of inserts bushing diameter 11x6mm

- Combined provision of inserts diameter 8x3mm and 6x3mm

- Marking laser for dmc

- Component slide laser / sprue funnel / qs drawer

- Stack conveyor system with lifting unit : conveyor belt 1: length 3200mm / width 1300mm / speed 6m/min // conveyor belt 2: length 2400mm / width 1300mm / speed 6m/min

Technical Machine Benefits

- Injection unit 1540 in horizontal machine length axis with screw diameter 50 mm

- 2x hydraulic core pullers (2-fold)

- Thermoplastic equipment: bimetallic screw cylinder type: x 102

- Standard 3-zone screw aps with improved abrasive wear protection

- Cooling water battery with 10 control circuits

- Clamping force 2750 kn / plate distance max. 1580 mm

- Clear column distance 660 x 660 mm / mold installation height minimum 400 max 950 mm

- Mold opening stroke 610 mm / robust mono toggle lever for 50 tons and 80 tons

- Lifting unit: length 1000mm / width 1300mm / speed 6m/min / stroke approx. 450mm max. / load 150lg lifting / speed 2,5/min

Extra Information

Scope of delivery is machine without automation. The automation solution is not included in the price but is for sale at additional cost.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing