Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

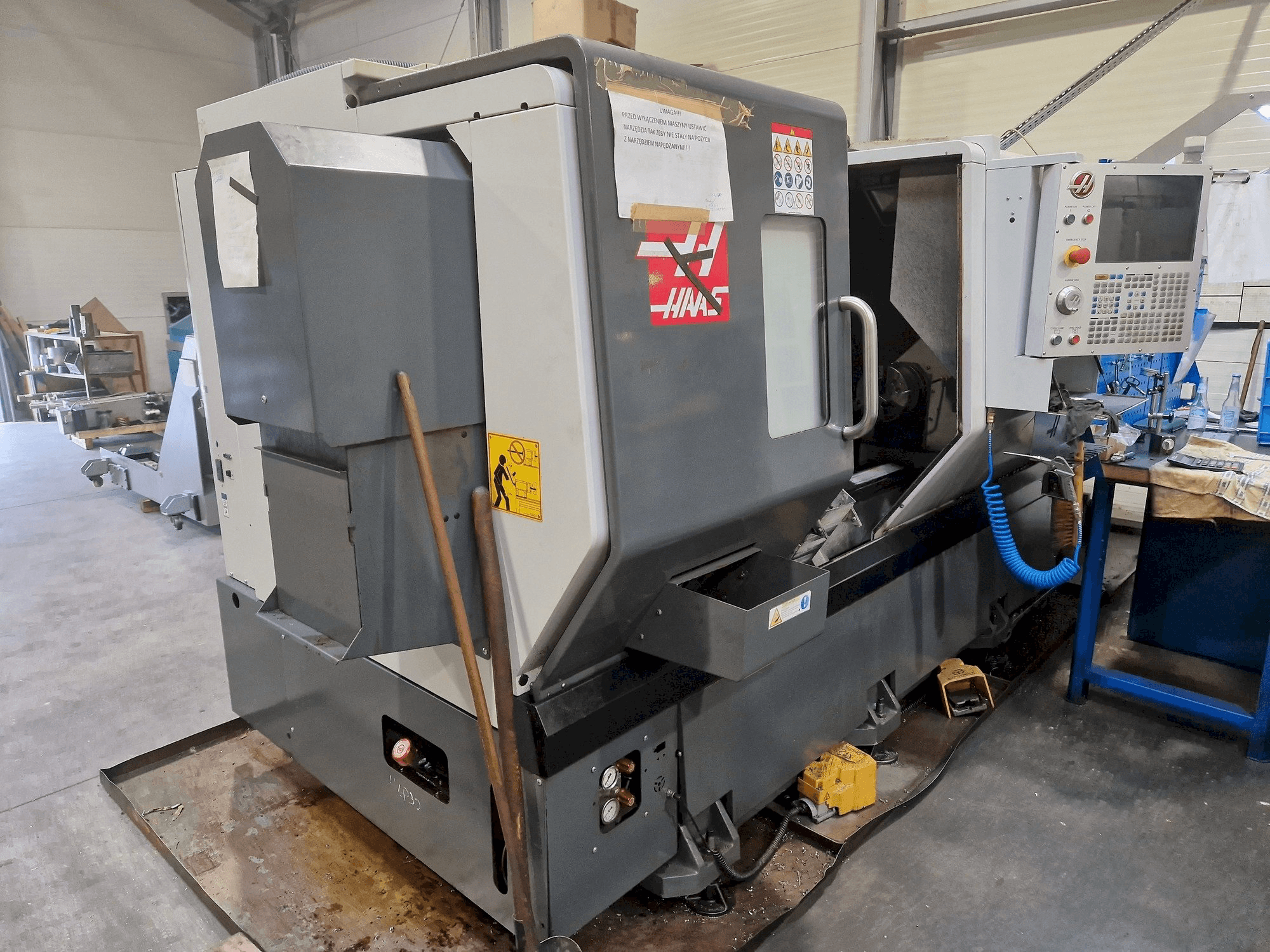

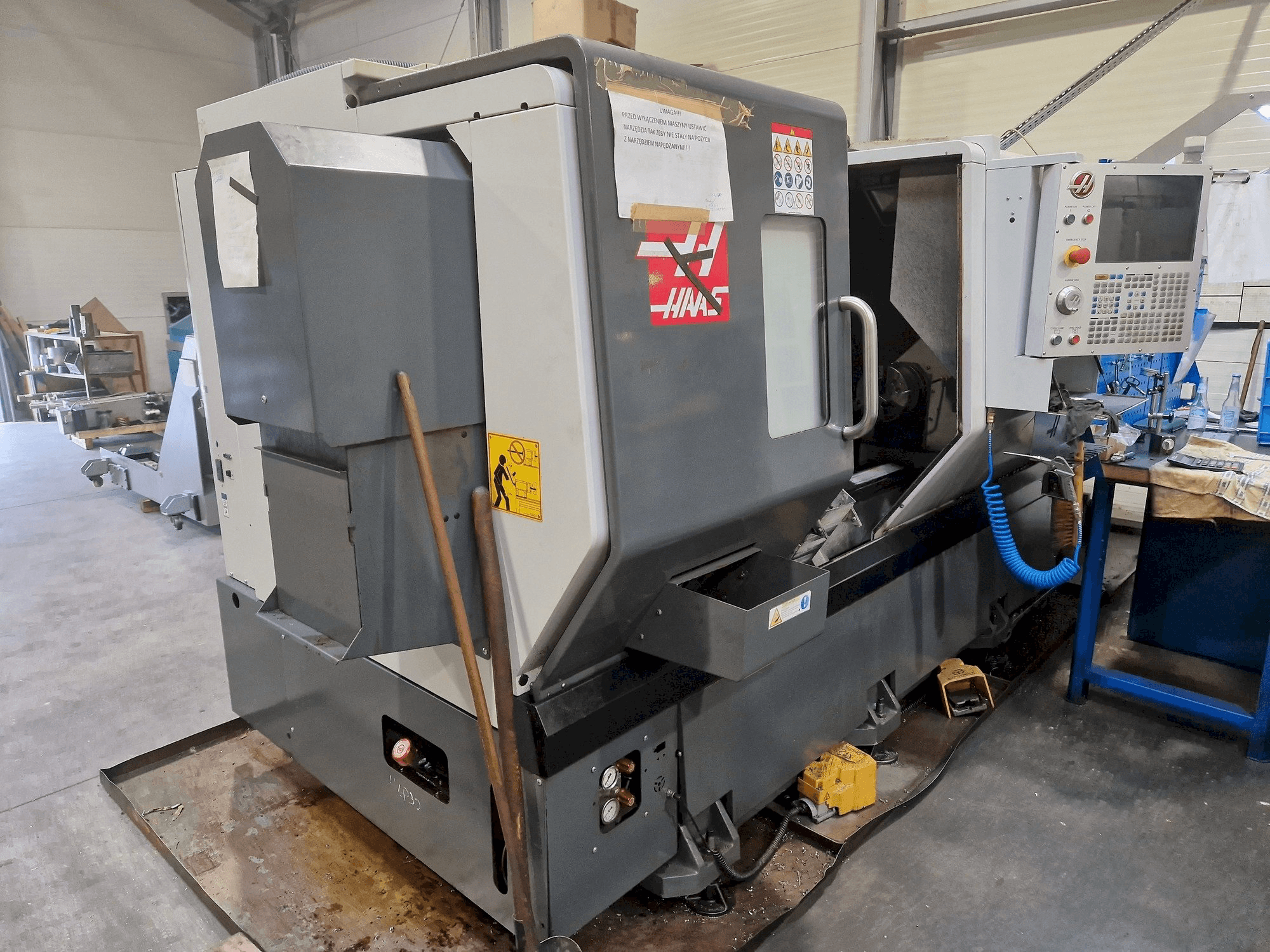

HAAS - DS-30YPL-TUR-HAA-2018-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- HAAS DS-30Y (2018) lathe

This HAAS DS-30Y (2018) lathe was made in the year 2018 in the United States. It is equipped with a Haas control unit. The machine has a 2 spindle with a spindle speed of 4800 rpm. In total it operated 10635 power on hours and 3608 cutting hours.

Overview

- brand: HAAS

- year: 2018

- MODEL: DS-30Y

- production hours: 3608

- application type: Turning

- Location: Poland

- machine type: Turn-Mill Centre

- control unit brand: HAAS

Technical Information - HAAS DS-30Y

Control Unit

- Control Brand: HAAS

Dimensions

- Machine Depth: 2290 mm

- Machine Height: 2340 mm

Movement

- X-axis Travel: 318 mm

- Y-axis Travel: 50 mm

- Z-axis Travel: 584 mm

Technical Specification

- Spindle Power: 22.4 kW

- Spindle Speed: 4800 RPM

Additional Information

Additional equipment

- Driven tools (6000 min-1) with C-axis

- Measuring probe

- High-pressure cooling system (21bar)

- Bar feeder interface

- Belt chip conveyor

- IFS Vario E2000 filtration system

- Programmable workpiece pick-up system

- Equipped with 15 tool holders

Machine Benefits

Qualitative Machine Benefits

- Ds-38ss 254 mm chuck, spindle bore 76 mm, 22. 4 kw engine, speed: 4,500 rpm - pcat programmable, pneumatically operated parts catcher system, maximum part dimensions: 96 mm x 152 mm for st-20, st-25, st-30, st-35, ds-30 also in y axes

- Pcat programmable, pneumatically operated parts catcher system, maximum part dimensions: 96 mm x 152 mm for st-20, st-25, st-30, st-35, ds-30 also in y axes

- Acf additional 25 μm filtration system, indispensable for processing cast iron, aluminum, wood, and composite materials

- Hpc high-pressure coolant system, pressure up to 21 bar

- Ethernet network card

- Conveyor automatic parts ejector

- Jet actuated by the m code, air blast through the chuck

- Lt-bmt65-24 24-station bmt65 turret (24 positions indexable) instead of the standard 12-station bmt65 turret

Technical Machine Benefits

- Cross slide travel on x-axis: 318 mm - cross slide travel on y-axis: +50 mm - longitudinal slide travel on z-axis: 584 mm

- Swing diameter over cross slide: 527 mm - swing diameter over tailstock: 806 mm

- Diameter of the main spindle chuck: 210 mm - diameter of the main spindle bore: 88. 9 mm - maximum turning diameter with bar work: 51 mm - maximum turning diameter for bmt65 hybrid turret: 454

- Cnc control, 4 axes (including y axis, haas type, compatible with fanuc), memory capacity 1 mb, 15” lcd monitor with usb port

- Electronic hand wheel

- Tool holder type bmt65, with a set of standard holders, driven tools

- Hydraulic three-jaw chuck with soft jaws for main spindle, hydraulic collet chuck with soft jaws for sub-spindle

- Compensation of thermal expansion of ball screws, cabinet with double doors and windows, operation without compensation bracket, installation of air connection

- Tray with a roll-out chip conveyor, automatic central lubrication system, cabcool - cnc control panel cooling

- Lighting of the machine interior, machine documentation in english and polish, initial filling with blaser coolant

Extra Information

15 pcs of tool holders // POWER ON HOURS = 10635h // CUTTING HOURS = 3608h

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing