Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

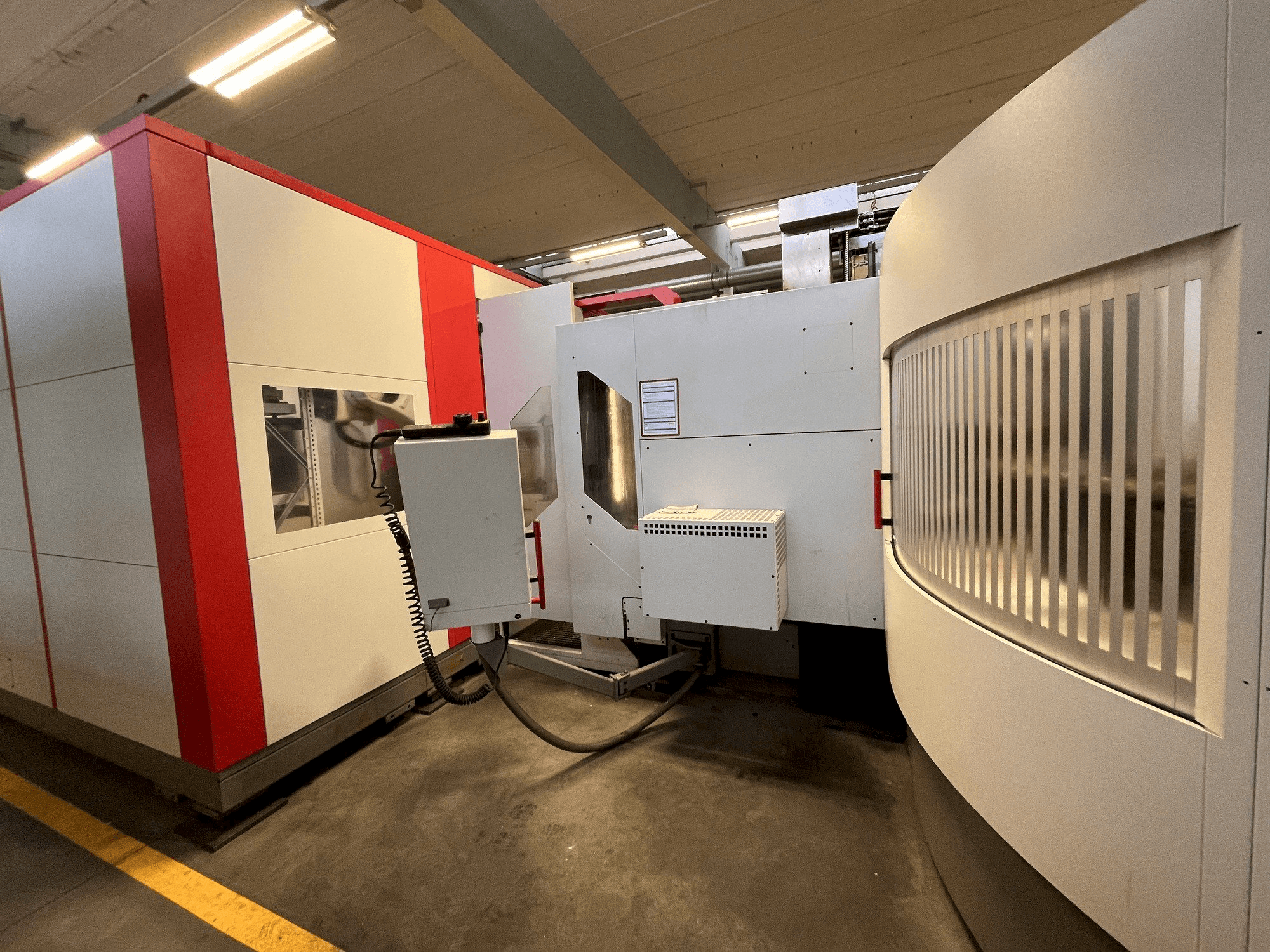

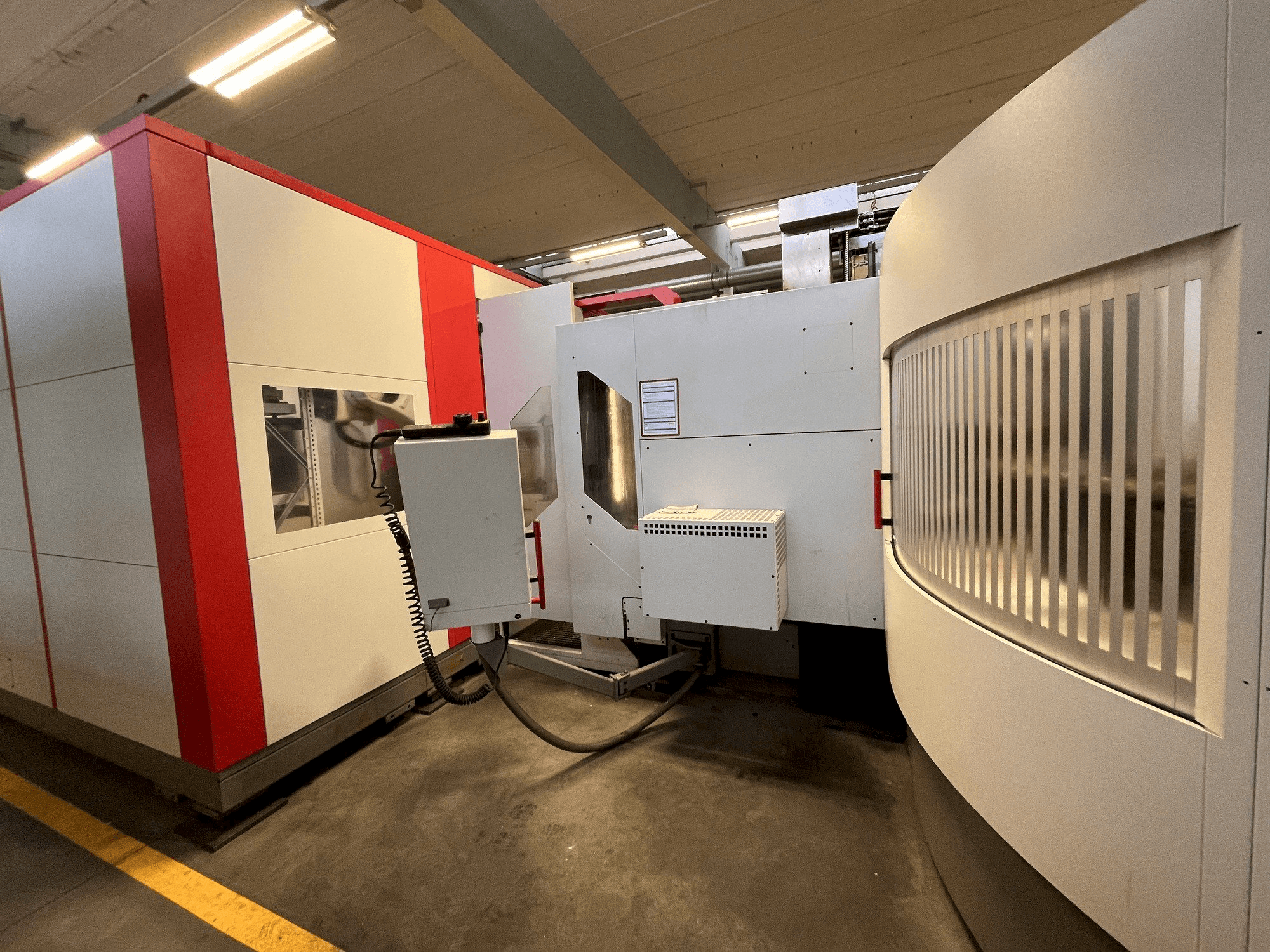

HERMLE - RS1 Robot SystemDE-MIL-HER-2009-00003

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- HERMLE RS1 Robot System

This HERMLE RS1 Robot System of 2 units Hermle C30 U, 5 axis vertical machine center made in the year 2009 and 2008 are equipped with a HEIDENHAIN iTNC 530 control unit and has a spindle speed of 18000 rpm. The system comes with an Automation KUKA KR 150-2 2000 Robot built in 2008 that has 6 axes with a maximum pallet weight of 140 kg.

Overview

- brand: HERMLE

- year: 2009

- MODEL: RS1 Robot System

- application type: Milling

- Location: Germany

- machine type: Vertical Machining Centre

- control unit brand: HEIDENHAIN

Technical Information - HERMLE RS1 Robot System

Control Unit

- Control Brand: HEIDENHAIN

- Control Model: ITNC 530

Movement

- Number of Axes: 5

- X-axis Travel: 650 mm

- Y-axis Travel: 600 mm

- Z-axis Travel: 500 mm

Technical Specification

- Max. Tool Weight: 8 kg

- Number of Tools: 32

- Spindle Speed: 18000 RPM

Additional Information

Additional equipment

- the cell comes with 25 pallets without vise 1 pallet on each machine and 23 on the automation

- come with Renishaw touch-probe

- Chip conveyor is included

- The inner coolant high pressure pump is not included

Machine Benefits

Qualitative Machine Benefits

- Robot kuka kr 150-2 2000:

- 6 axis, weight: 1267 kg, master computer that runs on windows 10, and soflex pcs run on windows xp. Pallet rack 300x300 with 24 places - 22 of which are pallets in the rack, 3 of which are power clamping blocks for clamping automatic clamps.

- 2 cubic, 1x cylindrical - 1x manual clamping block

- Pallet rack 400x400 with 18 spaces - of which 17 pallets are in the rack

- Raw material storage locations:

- 2x raw material storage areas for cubic parts, 60 spaces available per storage area. Raw material with the dimensions 50x15 can be loaded. - 2x raw material trays for cylindrical parts, 56 places available per tray. Parts with a 6mm spigot can be loaded.

- 2x additional gripper: 1x for cylindrical, 1x for cubic parts

- Kuka with 6 axes with a maximum pallet weight of 140 kg - kuka manual control unit raw material loading via external set-up station

- Soflex order management version 4. 27

- Master computer runs on windows 10, soflex pcs runs on windows xp

Technical Machine Benefits

- Rapid feed: 45000 mm/min - nc swivel rotary table diameter 280

- With erowa clamping system 160 mm throat dimension - mts base plate 320p/a 2-f. MediaÜ. 2-fold

- Rotary table - ikz - chip sorter

- Compressed air supply spindle center - automatic cabin door - status light

- Bed winding - manual cabin roof - losma extraction system

- Electronic handwheel - hinged belt conveyor - place additional magazine: 157

- Tool magazine: 157 slots, 6 fold feed through, automatic door, temperature compensation

- Number of loading and unloading bays: 8

- Tool measurement: blum wz breakage/measurement a1

- Touch probe: 2x renishaw omp 40-2ls, plc extension 2nd measuring probe

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Documents

Borja Garcia

Payment Terms

Payment in advance

Asset Financing

Products related to HERMLE RS1 Robot System

VMX 60

Hurco - Vertical Machining Centre

CMX 70U

DMG MORI - Universal Machining Centre

VF 2 SS

HAAS - Vertical Machining Centre

EC-400

HAAS - Horizontal Machining Centre

ACE HP 4000

DAEWOO - Vertical Machining Centre

V85

MTcut - Vertical Machining Centre

MCPH150 UNIPRO 90

HELLER - Horizontal Machining Centre

DMC-63V

DECKEL - Vertical Machining Centre

DMC 60T

DMG DECKEL MAHO - Universal Machining Centre

PICOMAX 55 CNC 2/3

FEHLMANN - Vertical Machining Centre

C 800 V

HERMLE - Vertical Machining Centre

VCN 700E/40-II

Mazak - Vertical Machining Centre