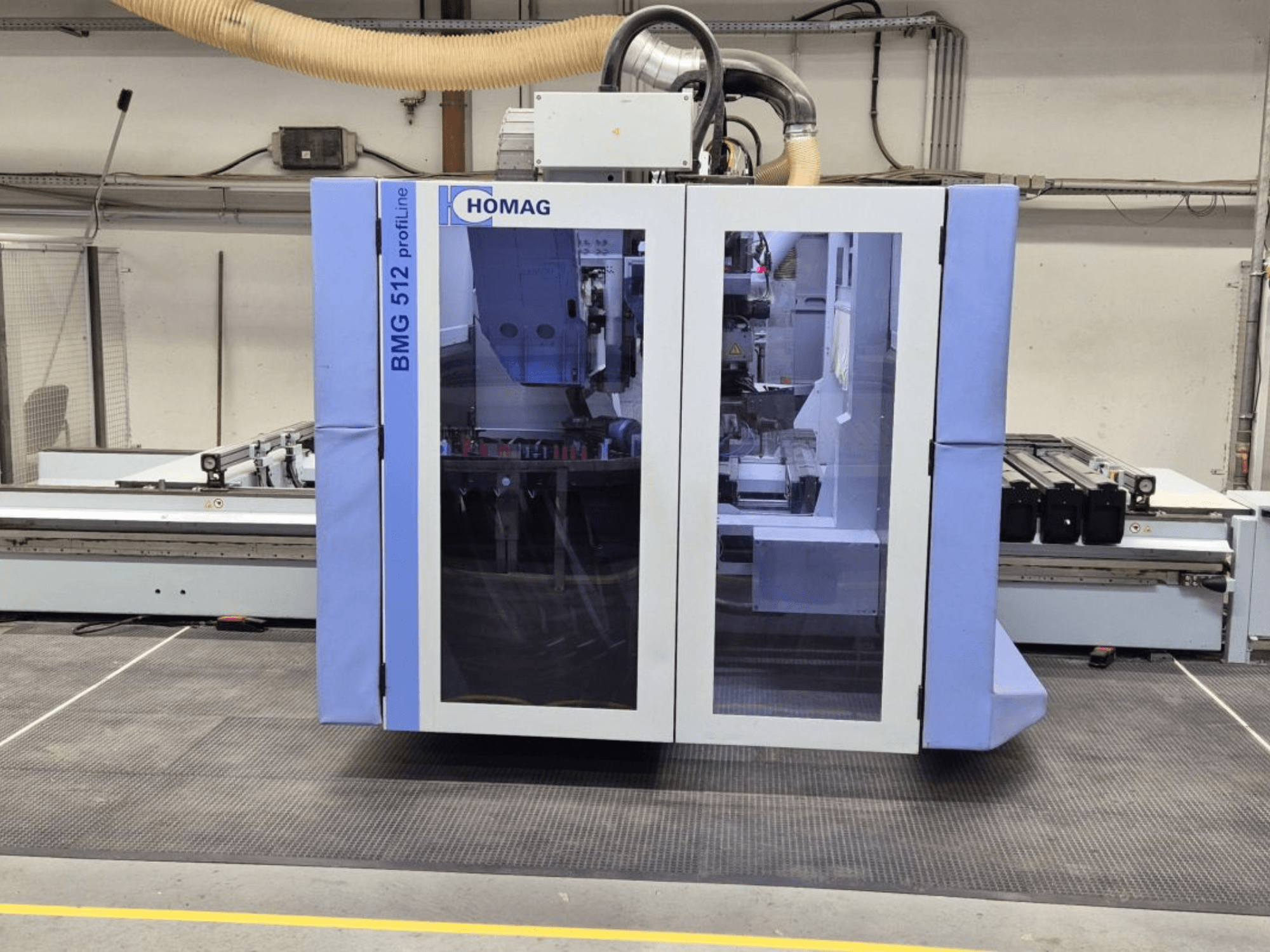

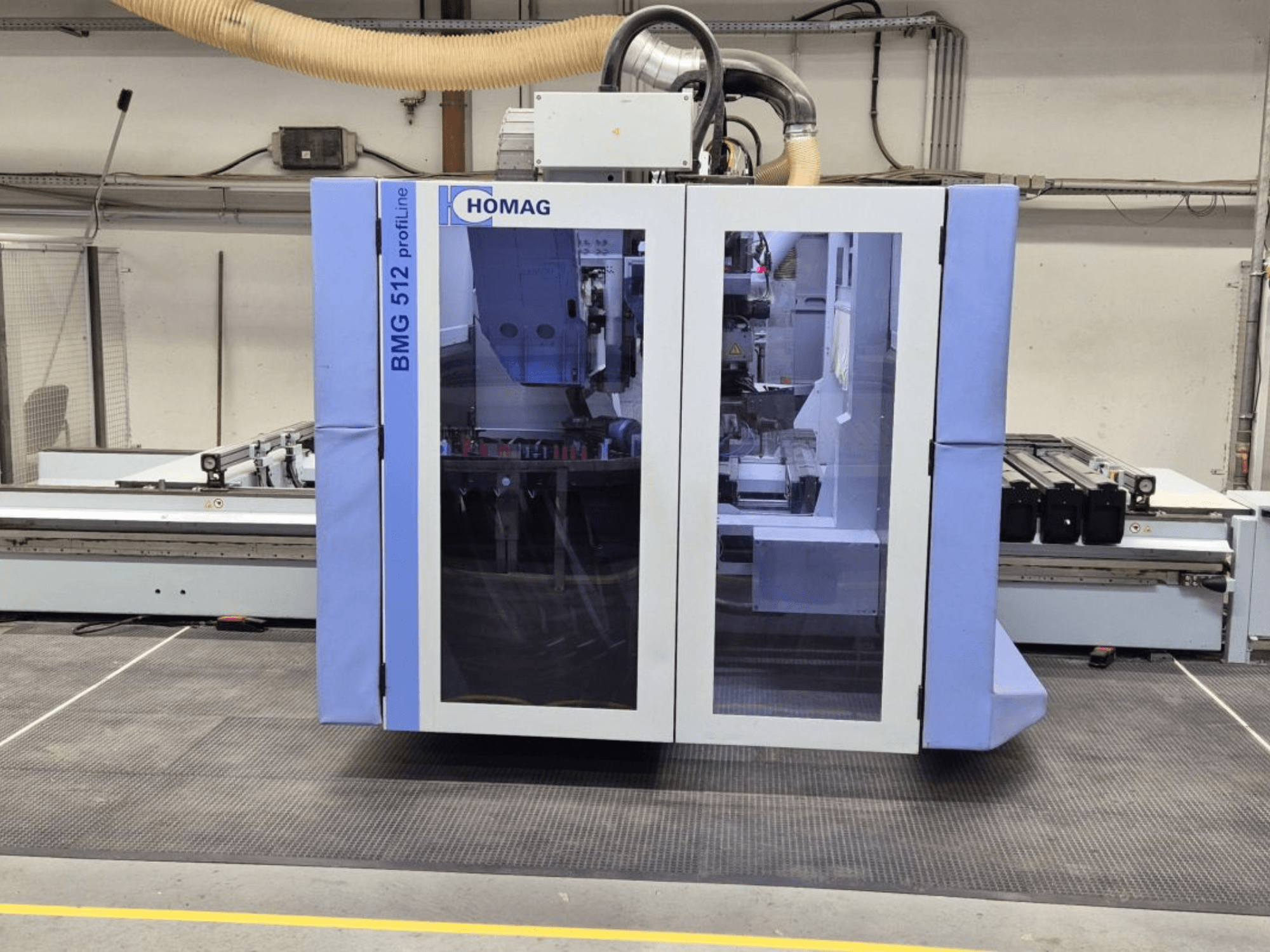

HOMAG - PROFI BMG 512/40/12/V/ADE-CNC-HOM-2016-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Wood Working

- ➤ Used HOMAG PROFI BMG 512/40/12/V/A | Processing Center

This 4-axis HOMAG PROFI BMG 512/40/12/V/A was manufactured in 2016, featuring a POWEREDGE gluing unit and a 4-fold edge magazine. It includes an 18-fold disc tool-changer, a 12 kW processing spindle, and a C-axis with unlimited swivel range. The machine supports workpiece lengths up to 4000 mm and thicknesses up to 300 mm. Ideal for advanced woodworking, it offers dynamic space allocation for optimal processing area utilization. Contact us for more information about this machine.

Overview

- brand: HOMAG

- year: 2016

- MODEL: PROFI BMG 512/40/12/V/A

- application type: CNC Wood Machining

- Location: Germany

- machine type: CNC Processing Center

Additional Information

Additional information

Workpiece

Lengths: 4000 mm for single placement / 2250 mm for pendulum placement

Widths: 1450 mm for all units and front stop

Maximum Workpiece Thickness: 300 mm (including clamping devices)

Up to 60 mm with standard clamps without restrictions for units and extraction.

Table

Automatic Console Table

Automatically adjustable console table

8 consoles Y = 1500 mm

16 side and stop pins 140 mm, electromechanically controlled

Dynamic space allocation for optimal utilization in pendulum operation

Various double vacuum clamps

Without vacuum pump; supplied via a building-side vacuum system

Tools

18-fold disc tool-changer

Main Drive

Processing Spindle: 12 kW (S6 operation) / 9.5 kW (S1 operation)

Spindle with hybrid bearings

Frequency-controlled rotation: 0 - 24000 rpm

Automatic feed reduction with decreasing spindle speed

Injection Unit

POWEREDGE Gluing Unit

Gluing unit for 360° edge gluing on butt joints

Glue application via application roller onto edge material

1 pressure roller Ø 50 mm, 1 follow-up roller Ø 35 mm

Max. edge height: 65 mm

Edge thickness: 0.4 - 3 mm (veneer 0.4 - 2 mm / PVC 1.0 - 2 mm)

Hot air nozzle for heating thick edges on small radii, controllable via NC

Machine Control

POWERCONTROL PC 86 POWERTOUCH

With 21.5" Full-HD multitouch display

WoodWOP for graphical, dialog-oriented creation of CNC programs

Diagnostic system WOODSCOUT

Additional Equipment

Interface for FLEX 5 unit

C-axis with unit interface

Unlimited swivel range

Coupling element for automatic tool change of FLEX 5 unit

Drilling Head

21 spindles V17 / H4 / S0 / 90°

17 vertical drilling spindles with quick-change system

T-shaped arrangement: 7 spindles in Y-direction / 11 spindles in X-direction

4 horizontal spindles with saw 0 / 90°

Pre-cutting Station

Moves with the processing portal (X-axis)

Saw / Trimming Unit for Tool Changer

Combined trimming and corner rounding unit, sensor-controlled

Combined flush-trim / pull-knife unit

Extra Information

Coolant tank for processing spindle

Integrated chip conveyor, discharging to the left

Note: The technical data and descriptions are for informational purposes only and are not binding.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing