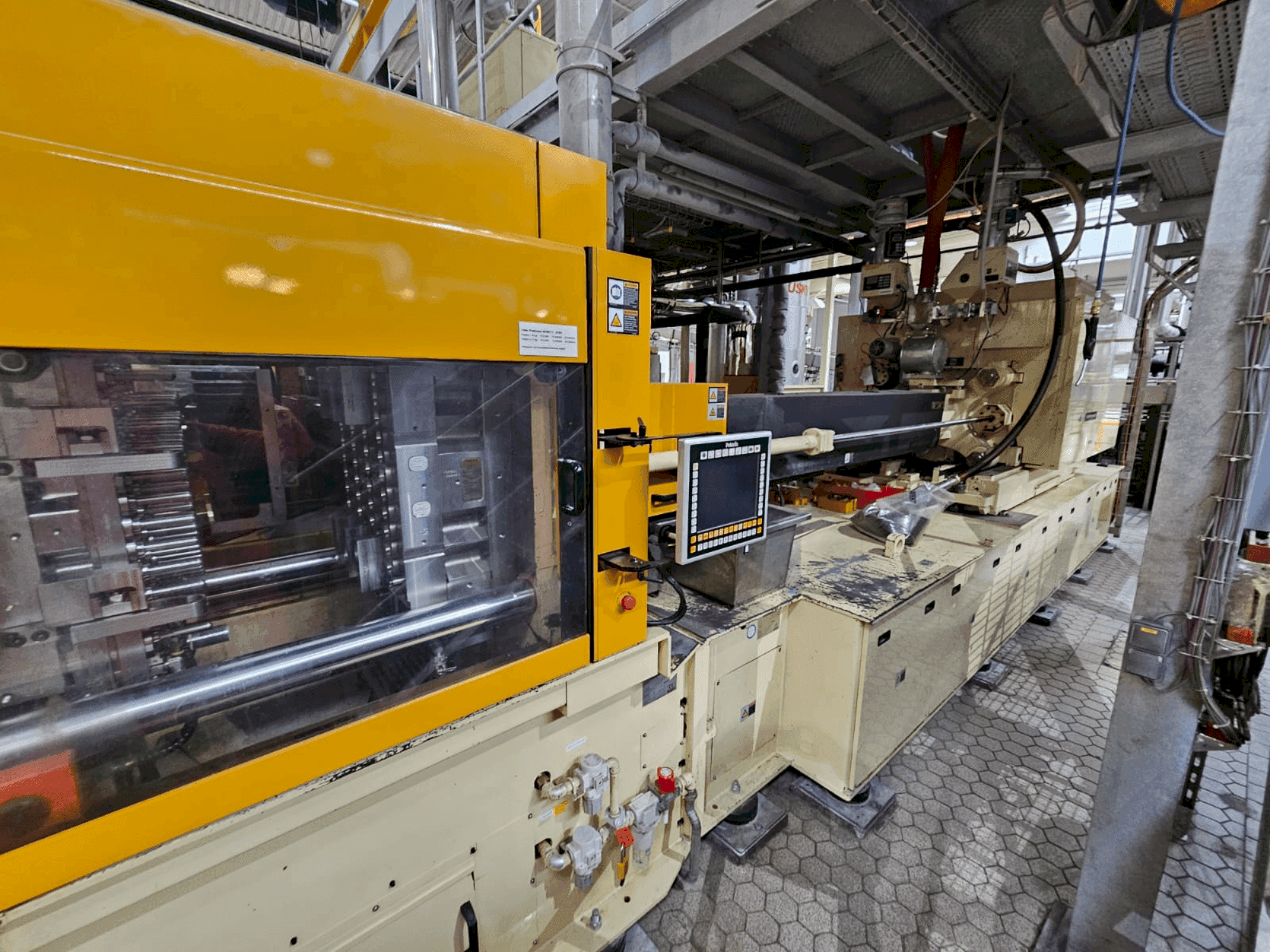

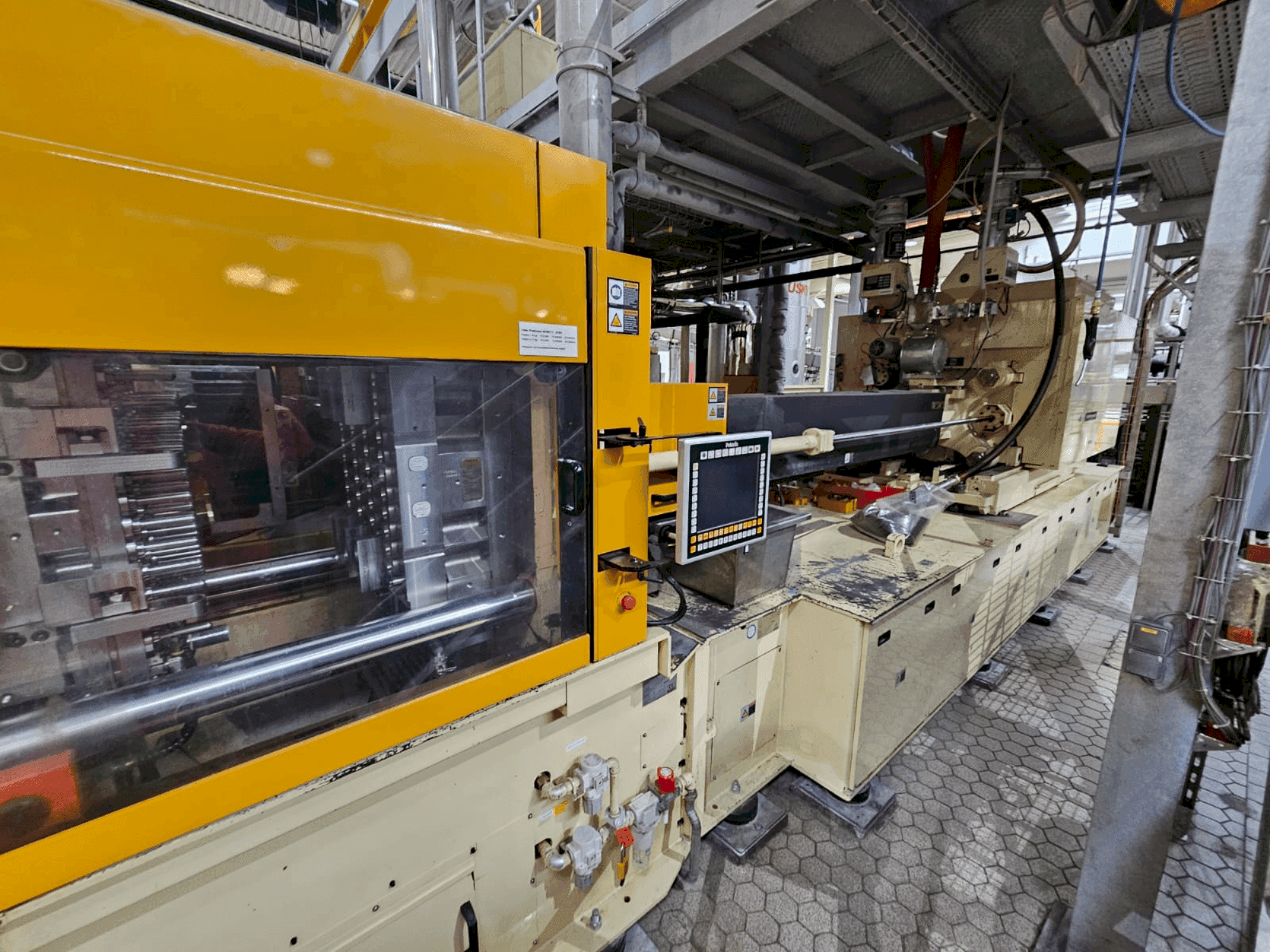

Husky - HPETL230E-RSE95D-95AT-INJ-HUS-2015-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Plastics Processing Machinery

- ➤ Used Husky HPETL230E-RSE95D-95 For Sale | gindumac.com

This Husky HPETL230E-RSE95D-95 was manufactured in 2015. It is an all-electric injection molding system with a maximum throughput of 390 kg/h PET and a max shot weight of 2424 g PET. The clamping unit is fully electric with a toggle drive, and it features an integrated control system for additional equipment. Consider the opportunity to buy this Husky HPETL230E-RSE95D-95 electrical injection moulding machine. Contact us for more information about this machine.

Overview

- brand: Husky

- year: 2015

- MODEL: HPETL230E-RSE95D-95

- application type: Injection Moulding

- Location: Austria

- machine type: Electrical Injection Moulding Machine

Technical Information - Husky HPETL230E-RSE95D-95

Technical Specification

- Max. Shot Weight: 2424 g

Additional Information

Additional equipment

- Mold Dehumidifier: Incl. hood, spare parts package, piping

- Conveyor Belt: Two-sided preform filling system for cartons/grid boxes

Machine Benefits

Technical Machine Benefits

- The package includes two machines along with additional components such as pellet silos, pellet feeder, discharge system for foreign bodies in pellets, dosing unit for color, and platform. Everything seen in the pictures is included.

- Max throughput: 390 kg/h pet

- Clamping unit: fully electric with toggle drive

- Clamping platen: movable, guided on rollers

- Type: split version

- Dryer: dr815ht-g3 with 4000-liter drying hopper (stainless steel, insulated)

- Husky 1: 3 tools - 28 gauge muzzle, 17. 8/26/30. 3 grams

- Husky 2: 2 tools - 38 gauge muzzle, 18/29 grams

Extra Information

Clamping Force Clamping Unit: Fully electric with toggle drive Clamping Platen: Movable, guided on rollers Control Unit Control System: Integrated control system for additional equipment Display for Mold Cooling Water Temperature/Pressure (Flow and Return) Control Output for Color Dosing Unit Lubrication System: Automatic Post-mixing Device: Integrated in the nozzle Tools 48-cavity H-PET Injection Mold Preform Weight: 17.8 g and 30.26 g Punch Size: 50 x 140 mm Includes: 3-position removal plate, basic spare parts package 32-cavity H-PET Injection Mold Preform Weight: 18 g and 29 g (38 mm Bericap) Punch Size: 63.5 x 140 mm Includes: 3-position removal plate, basic spare parts package Functions Temperature Monitoring and Setting Continuous Level Meter Variable Dew Point Setting Conveying: Hot transport of the granulate via vacuum unit P07 to the booster hopper (HAD400) Paint Mixing Units For Solid Paint: Volumetric, 4 dosing screws For Liquid Paint: 4 dosing pumps Preform Production Specifications Preform Weight: 17.80 g Mouth: PCO1881 LW Length: 89.35 mm Wall Thickness: 3.06 mm Base: 2.30 mm Shape: Bell Cavities: 48 Cycle Time: 12.4 ±0.3 s Preforms per Hour: 13935 Annual Production (95% availability): 111205000 Throughput (kg/h): 248 Power Consumption: 506 Wh/kg PET Preform Weight: 29.00 g Mouth: Bericap 38 Length: 108.59 mm Wall Thickness: 3.16 mm Base: 2.42 mm Shape: Bell Cavities: 32 Cycle Time: 13.7 ±0.3 s Preforms per Hour: 8409 Annual Production (95% availability): 67101000 Throughput (kg/h): 244 Power Consumption: 532 Wh/kg PET Preform Weight: 18.00 g Mouth: Bericap 38 Length: 82.04 mm Wall Thickness: 2.70 mm Base: 2.20 mm Shape: Bell Cavities: 32 Cycle Time: 11.3 ±0.3 s Preforms per Hour: 10195 Annual Production (95% availability): 81353000 Throughput (kg/h): 184 Power Consumption: 506 Wh/kg PET Preform Weight: 30.26 g Mouth: PCO1881 LW Length: 122.30 mm Wall Thickness: 3.00 mm Base: 2.30 mm Shape: Grade Cavities: 48 Cycle Time: 14.7 ±0.3 s Preforms per Hour: 11755 Annual Production (95% availability): 93805000 Throughput (kg/h): 356 Husky1 PCO 1881 30,3g 1-1,5l PCO 1881 26,0g 1-1,5l PCO 1881 17,8g 1-1,5l Husky2 38er Bericap 29g 1-1,5l 38er Bericap 18g 0,5l

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing