Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

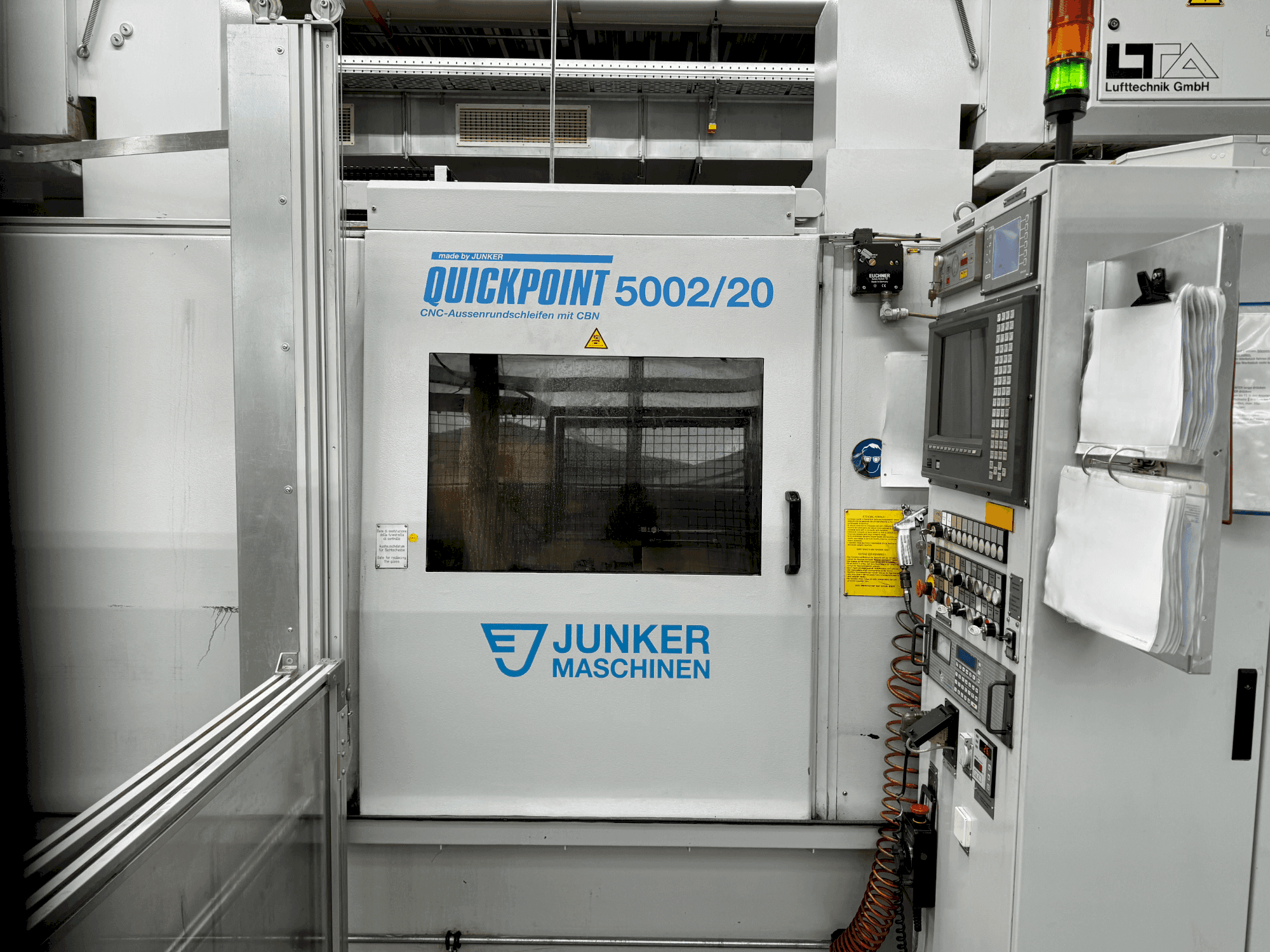

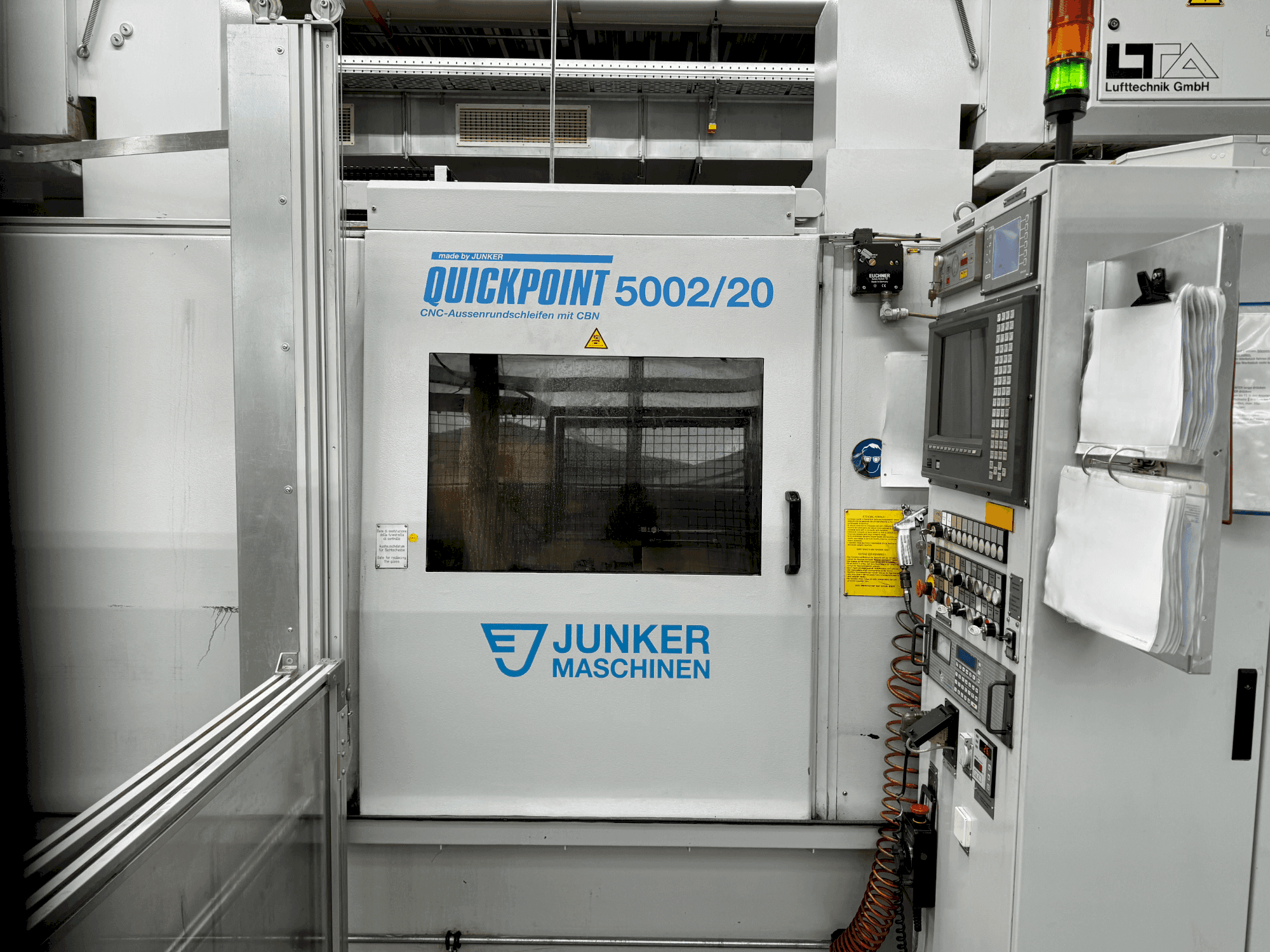

JUNKER - Quickpoint 5002/20DE-GRI-JUN-2000-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- JUNKER Quickpoint 5002/20 Cylindrical Grinding Machine

This JUNKER Quickpoint 5002/20 Cylindrical Grinding Machine was manufactured in the year 2000 in Germany. It has a grinding diameter of 280 mm and a grinding length of 900 mm. Equipped with a travel z-axis of 900 mm it can handle a max. workpiece weight of 30 kg. As control unit it has a FANUC 15-TB control. It comes with 2x extraction units (made by LTA) and an oil filter system (built in-house). The machine is currently used as part of a robot line and will be sold because of replacement by a new machine. See photo and video gallery for more impressions.

Overview

- brand: JUNKER

- year: 2000

- MODEL: Quickpoint 5002/20

- application type: Grinding

- Location: Germany

- machine type: Cylindrical Grinding Machine

- control unit brand: FANUC

Technical Information - JUNKER Quickpoint 5002/20

Control Unit

- Control Brand: FANUC

- Control Model: 15-TB

Dimensions

- Machine Depth: 5000 mm

- Machine Height: 2500 mm

- Machine Weight: 15000 kg

Movement

- Number of Axes: 3

- Z-axis Travel: 900 mm

Technical Specification

- Max. Workpiece Diameter: 250 mm

Additional Information

Additional equipment

- 2x extraction units (made by LTA)

- Oil filter system largely self-built in collecting tray, system with magnetic separator (probably only conditionally reusable, but currently functional), currently built in a cold split design with internal cooler and external condenser

- Replacement grinding wheels can be handed over if still available at dismantling date

- Further accessories, such as tips, driver systems, measuring probes etc. would also be available and could be given away

Machine Benefits

Qualitative Machine Benefits

- Machine always very well maintained

- Solid and reliable production line

- Quickpoint machines can be used for a wide range of applications, and at the same time boast impressive productivity

- Versatility and excellent workpiece quality

- 3 axes (x, z and b)

Technical Machine Benefits

- Loading system: manual

- Workhead: fixed

- Workpiece spindle // dimension: 100 x 400 mm, permanent grease lubrication, bearing protection by compressed air, drive by servo-motos (c-axis), cone and special fixture mk4 or junker standard collar ⌀ 75mm

- Tailstock // manually via chain wheel, chucking pressure adjustable via hydraulic

- Tailstock sleeve // ⌀ 100 x 430 mm, mk 4 resp. Junker standard collar ⌀ 75 mm

- Grinding table // z-axis (cnc-controlled)

- Wheelhead // infeed: x-axis (cnc-controlled), horizontal: -6° to + 15°, b-axis (cnc-controlled), vertical: -0. 5°, 0° and +0. 5° (op swivelling)

- Grinding spindle // ⌀ 180 x 400 mm, flange: ⌀ 190 mm, standard collar: ⌀ 127 mm, driving power: 24 kw

- Grinding wheel // borazon (cbn) or diamond, diameter: ⌀ 400 mm, bore: ⌀ 127 mm, coating width: 5mm

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing