Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

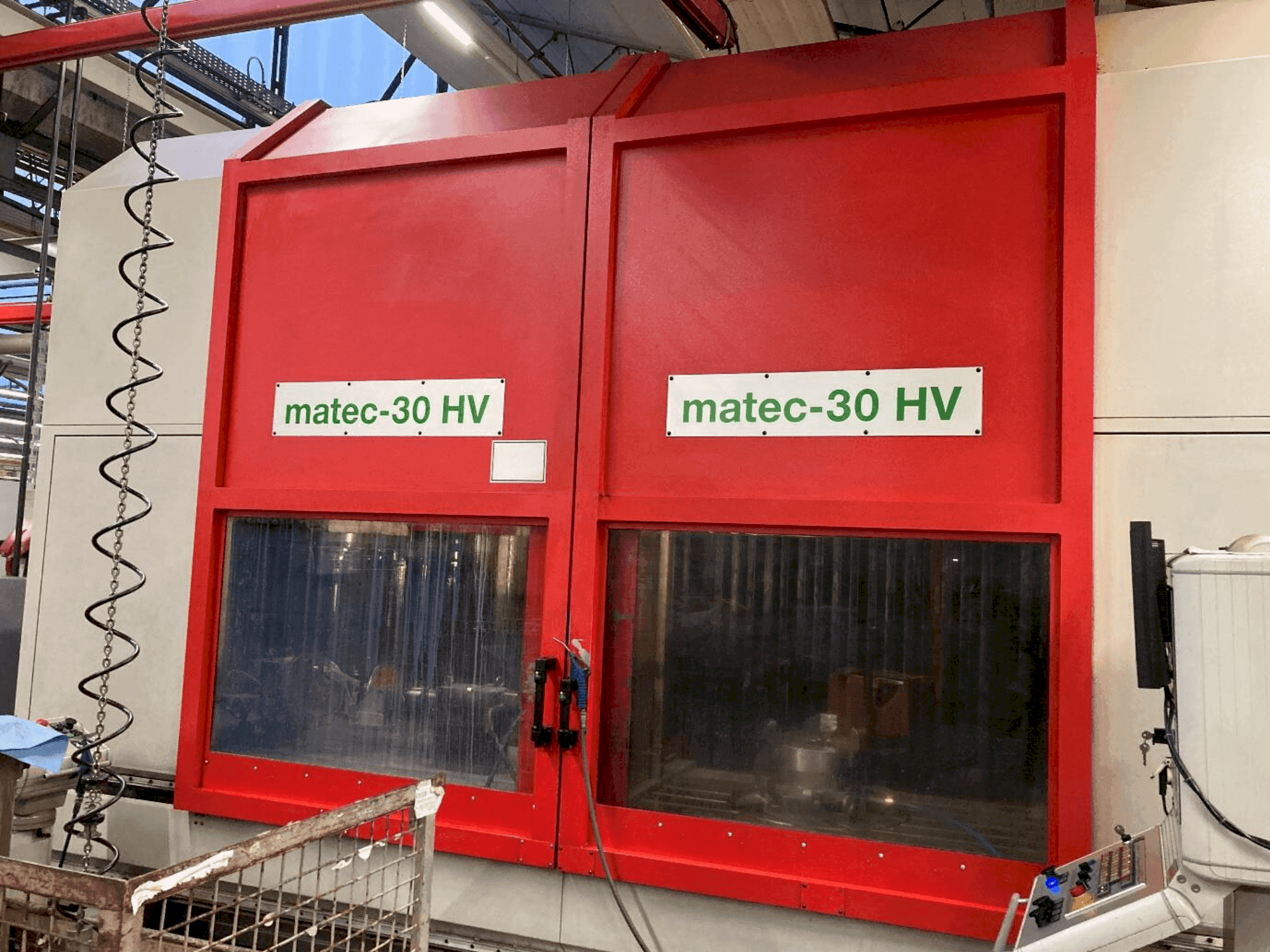

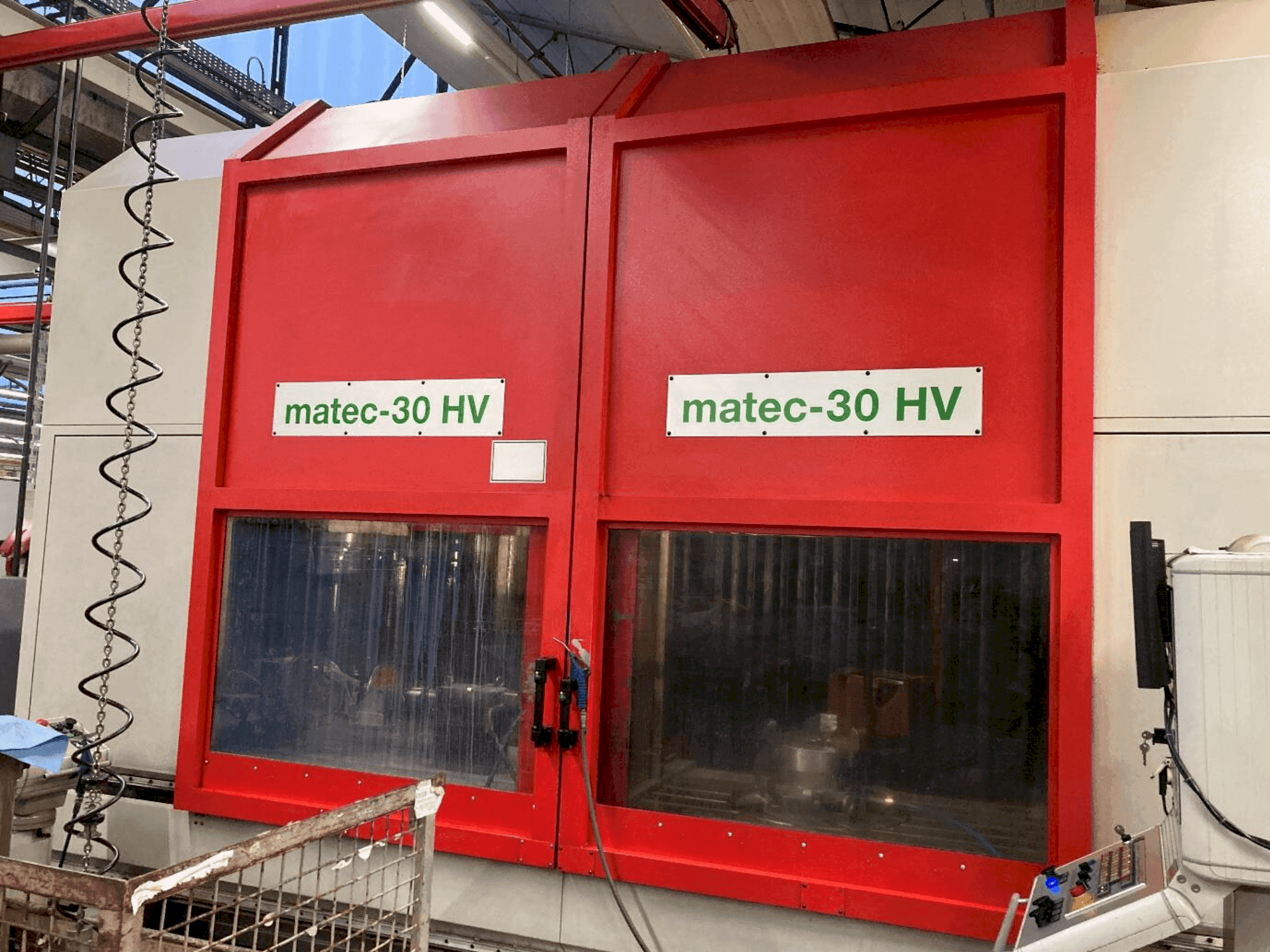

Matec - 30 HVDE-MIL-MAT-2003-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- MATEC 30 HV (2003) Universal Machining Centre / CNC traveling column milling machine

This MATEC 30 HV (2003) Universal Machining Centre was manufactured in 2003 in Germany. It is controlled by a BOSCH TYPE 3 OSA Control unit. This CNC traveling column milling machine (3+2 axes) is equipped with a main spindle type DMS 112 with speed range up to max. 12,000 min/-1 and drive power 30 kW. It has a NC swivel head (Sauter) with swiveling +/- 90 ° and graduation +/- 3 arc seconds. In addition it runs with a tool changer with 48 positions and a HSK A63 tool holder. The table is a NC rotary table with a clamping surface of 3,500 x 835 mm and 7 T-slots. IKZ 70 bar, paper belt filter and chip conveyor (ejection height 1200mm) and 3D radio measuring probe come with the machine. The machine is prepared with a 4th axis interface. The condition of the machine is very good - it is still in production and maintenance service has been applied regularly according to manufacturer's standards. An on-site inspection is possible at any time.

Overview

- brand: Matec

- year: 2003

- MODEL: 30 HV

- application type: Milling

- Location: Germany

- machine type: Vertical Machining Centre

- control unit brand: BOSCH

Technical Information - Matec 30 HV

Control Unit

- Control Brand: BOSCH

- Control Model: TYPE 3 OSA

Dimensions

- Machine Depth: 6000 mm

- Machine Height: 4000 mm

- Machine Weight: 15000 kg

Movement

- Number of Axes: 3

- X-axis Travel: 3000 mm

- Y-axis Travel: 800 mm

- Z-axis Travel: 1100 mm

Technical Specification

- Spindle Power: 30 kW

- Spindle Speed: 12000 RPM

- Through-spindle Coolant: Yes

Additional Information

Additional equipment

- Coolant system: Internal coolant supply 70 bar // Cooling unit for switch cabinet

- Paper belt filter Flushing gun

- Chip conveyor: Ejection height 1200mm

- 3D radio measuring probe

- Direct measuring systems x-y-z

Machine Benefits

Qualitative Machine Benefits

- Machine still under production and can be inspected at any time

- The machine has been serviced every year by the service department and is technically in good condition

Technical Machine Benefits

- Main spindle: type dms 112 // max. Torque 190 nm // drilling capacity steel approx. 60 mm // milling capacity approx. 500 cm³ // thread cutting m30

- Feed rates: rapid traverse (x / y / z) 30 m/min // feed speed 30,000 mm/min

- Nc swivel head: sauter swiveling +/- 90 ° // pitch +/- 3 arc seconds

- Work table: table clamping surface 3,500 x 835 mm // t-slots 7x // t-slots - width 18-h7 // nc rotary table sempuco skh 4/630 // horizontal faceplate // faceplate diameter 630mm // embedded in the machine table

- Tool changer: number of tool positions 48 pos.

- Total connected load: 60kva

- Fully enclosed work area

- Loading doors suitable for crane loading // automatic opening // movable partition wall

- Clamping hydraulics interface 4th axis // nc rotary table rw/nc 160/250 (hofmann)

- Face plate diameter 250mm // center height 160mm // hydraulic tailstock with quill mk4

Extra Information

Full documentation included // Declaration of conformity // Replacement screen installed

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing