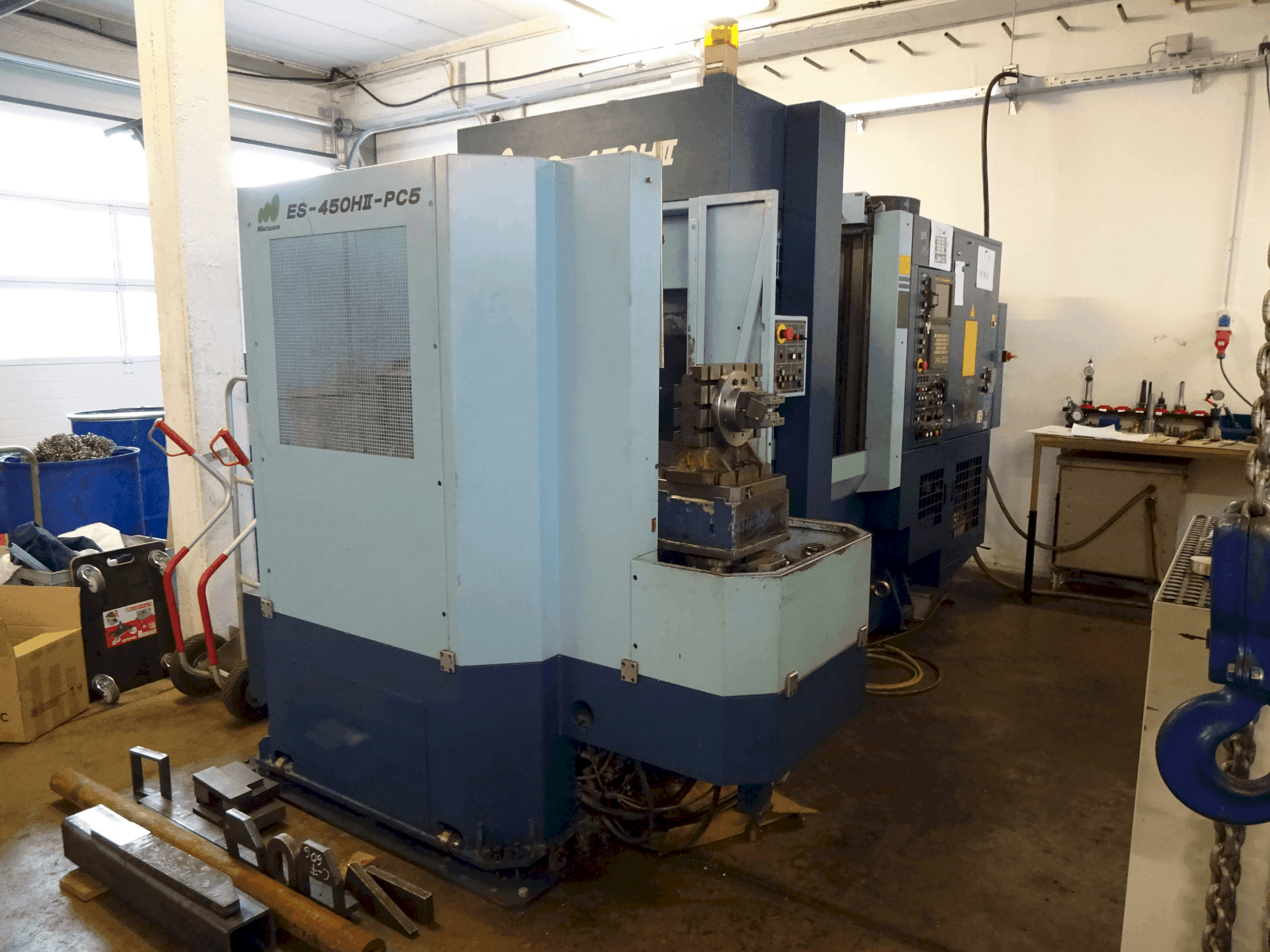

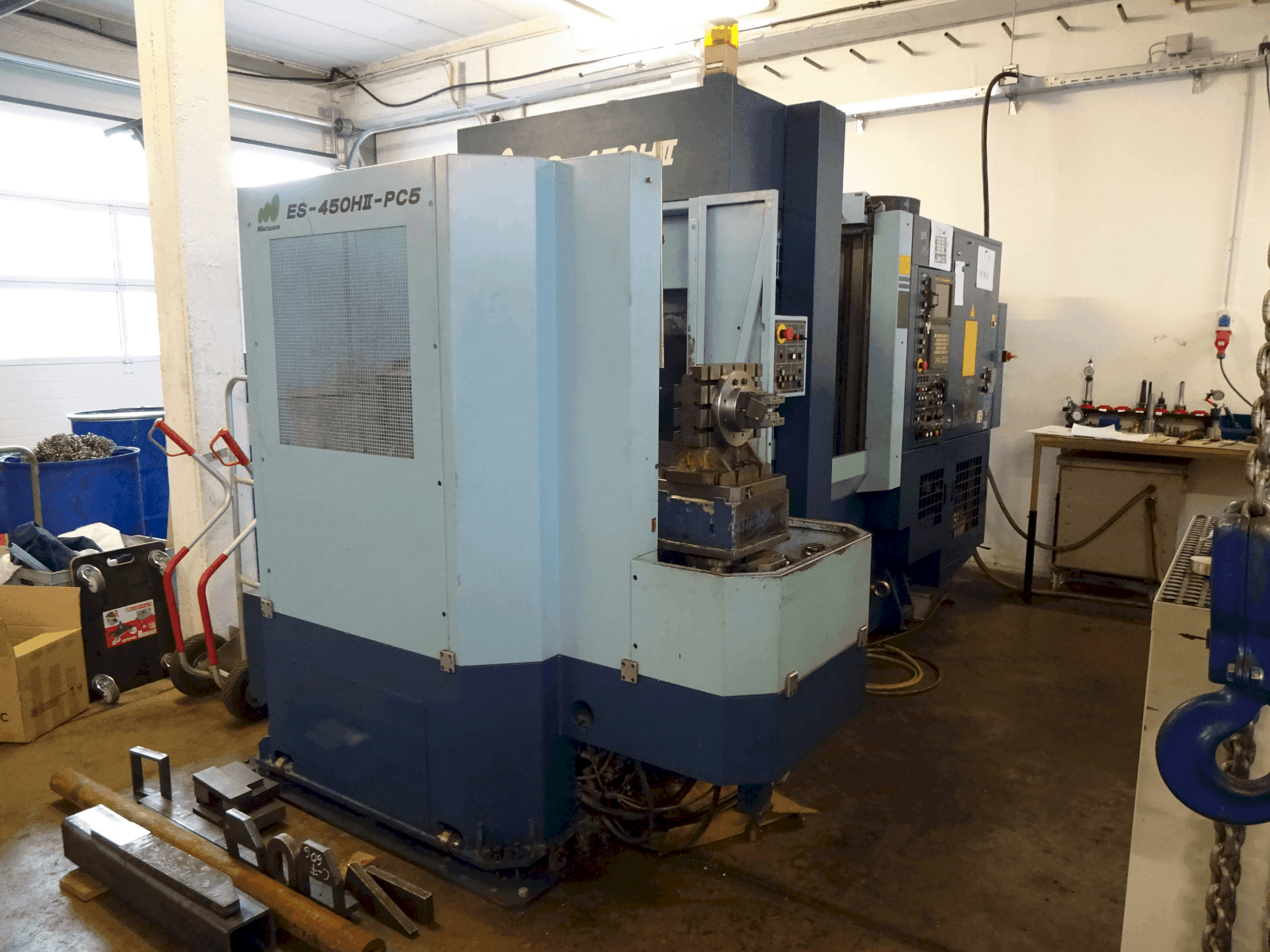

Matsuura - ES-450HII PC5DE-MIL-MAT-1999-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used Matsuura ES-450HII PC5 For Sale | gindumac.com

This 4-axis Matsuura ES-450HII PC5 was manufactured in 1999. It's a horizontal machining centre designed for precision and efficiency. If you are looking to get high-quality milling capabilities, consider the Matsuura ES-450HII PC5 machine we have for sale. Contact us for more information.

Overview

- brand: Matsuura

- year: 1999

- MODEL: ES-450HII PC5

- application type: Milling

- Location: Germany

- machine type: Horizontal Machining Centre

Technical Information - Matsuura ES-450HII PC5

Dimensions

- Machine Depth: 3600 mm

- Machine Height: 2470 mm

- Machine Weight: 5700 kg

Movement

- Number of Axes: 4

Technical Specification

- Max. Tool Weight: 8 kg

- Spindle Speed: 15000 RPM

Additional Information

Machine Benefits

Technical Machine Benefits

- Table surface height (from the floor): 1000mm

Extra Information

Traverses: X axis (column right/left): 450mm (250 on the left, 200 on the right) Y axis (spindle head up/down): 400mm Z axis (pallet back/forth): 400mm (+250 when pallet is changed) Workpiece Distance between pallet top surface to spindle nose: 80~480mm Distance between pallet centre to column slideways: 120~520mm Pallet: Working area: 300 x 300mm Maximum load weight: 200kg Surface tapped hole (size x quantity): M12 x P1.75 x 32mm Table Table indexing angle: 1 degree Table indexing speed: 1.5 sec/90°, 1.9 sec/180° Coupling clamp force: 27.3kN Spindle Spindle bearing ID: Ø70mm Maximum spindle torque: 105/1000 minˉ1 Nm Tool clamp force: 8.2kN Spindle orientation: Standard (electric) Spindle air blow: Standard Feed Rate Cutting federate (X/Y/Z): 1~15000mm/min Manual continuous (jog) federate: 0~4000mm/min Least output increment: 0.001mm Automatic Tool Changer Pull stud type: JIS B 6339 pull stud 40P Tool storage: 30 pcs Method of tool selection: Addresses code & random selection bi-directional magazine rotation. (T4) Tool change time (tool to tool): 1.5 sec (less than 6kg), 2.0 sec (more than 6kg) Tool change time (chip to chip): 3.2 sec Tool pot pitch: 95.25mm Automatic Pallet Changer Number of pallets: 2 Pallet change system: Turn-table method Pallet change time: 8.5 sec Pallet change time (pallet to pallet): 9.0 sec Pallet clamp force: 41.5kN Pallet weight/piece: 40kg Pallet size: 300 x 300mm Maximum load weight: 200kg Motors Spindle motor: Alpha T8/1500 AC 11.0/7.5kW (30min./continuous rate) Feed motors: X Axis: model α 22/3000 AC 4.4kW Y Axis: model α 22/2000 with brake AC 4.4kW Z Axis: model α 22/3000 AC 4.4kW Hydraulic motor: AC 1.5kW Lubrication motor: AC 0.02kW Coolant motor: AC 0.75kW Required Power Capacity Total electric capacity: 34KVA Air source: 0.54~0.93MPa Air capacity: 400 L/min Hydraulic tank capacity: 15L Lubrication tank capacity: 2.7L Coolant tank capacity: 200L Standard Attachments Tool enclosure guard (with top cover) Chip flow Synchronized tap Spindle oil cooler Spindle overload protection Feed axis interface prevention device Work light (fluorescent light) M code counter (9 kinds) Through spindle coolant Spindle probe interface (no probe) Filtermist Swarf conveyor Manuals

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing