Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

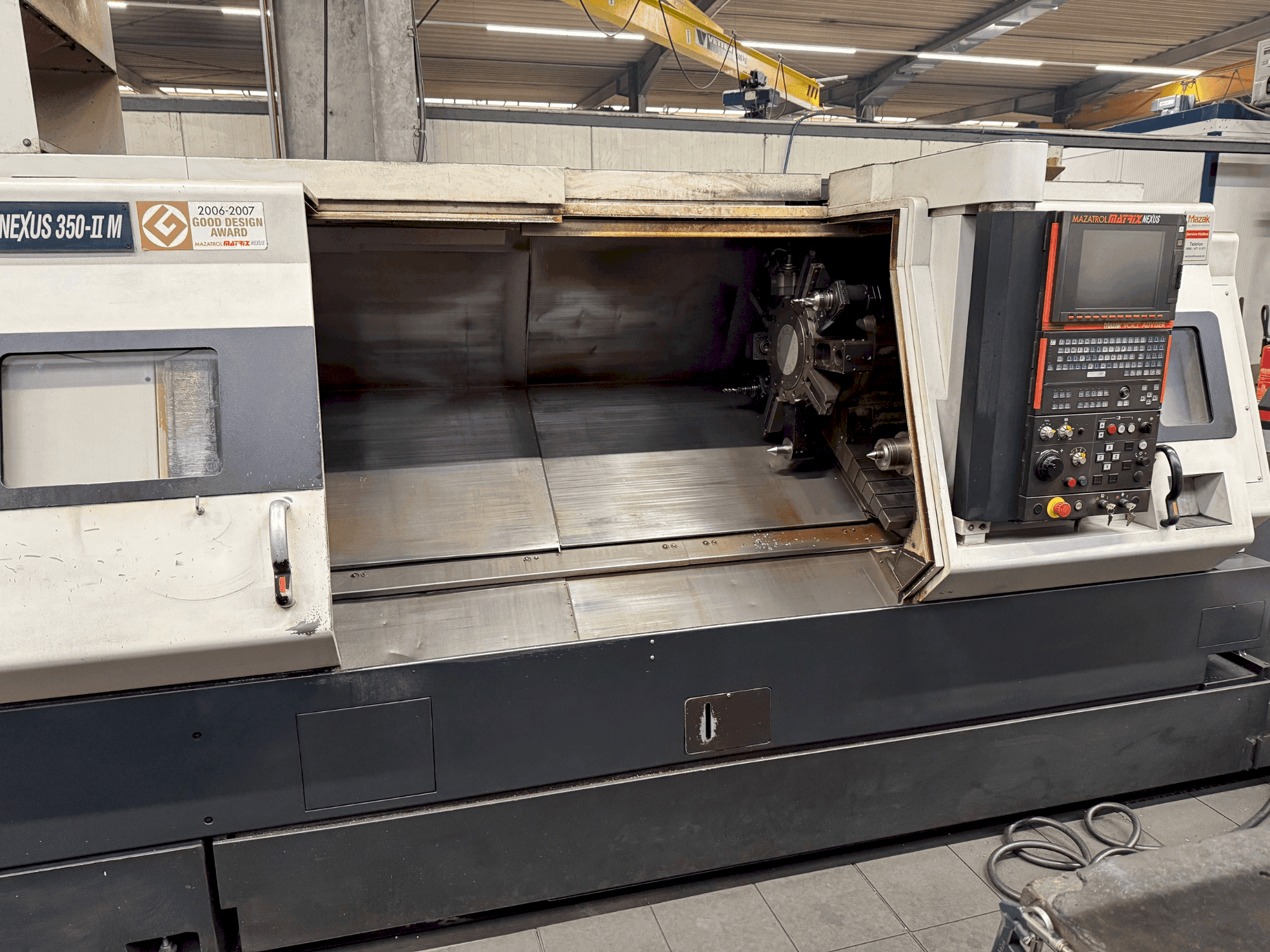

Mazak - Quick Turn Nexus 350-II MDE-TUR-MAZ-2007-00002

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used Mazak Quick Turn Nexus 350-II M | Horizontal Lathe

This 2-axis Mazak Quick Turn Nexus 350-II M was manufactured in 2007. Ideal for precision horizontal turning, this machine maintains robust functionality. A solid choice for enhancing your machining capabilities. Contact us for more information about this machine.

Overview

- brand: Mazak

- year: 2007

- MODEL: Quick Turn Nexus 350-II M

- application type: Turning

- Location: Germany

- machine type: Horizontal Turning Machine

- control unit brand: MAZATROL

Technical Information - Mazak Quick Turn Nexus 350-II M

Control Unit

- Control Brand: MAZATROL

- Control Model: MATRIX NEXUS

Dimensions

- Machine Depth: 4190 mm

- Machine Height: 2000 mm

- Machine Weight: 7705 kg

Movement

- Number of Axes: 2

Technical Specification

- Spindle Speed: 3300 RPM

Additional Information

Additional equipment

- Power transformer for the European market

- Hydraulic 3-jaw chuck (OD 315 mm), Hollow clamping device with material passage 102 mm

- Coolant and chip protection with fully enclosed work area

- Work area lighting

- Double foot switch

- Automatic cutting data transfer (VFC)

- Manual tool path memory function (TPS)

- Machining navigation prediction, monitoring, and result

- Preparation for chip conveyor attachment, rear ejection

- Automatic tool presetting device (Tool Eye)

Machine Benefits

Technical Machine Benefits

- Fast and precise production of threads by synchronising the milling spindle with the feed axis

- Simplified input of angular coordinates for turning operations

- Bed length: 1500 mm

- Opening in chuck: 102 mm / max. Chuck size: hydr 3-jaw chuck

- High-pressure coolant system (5 bar)

- Belt oil skimmer

- Chip conveyor lateral ejection (hinged belt version) / coolant tank 195kg, chip conveyor 500kg

- Cnc-controlled lathe

- Version: u1500

- Kitagawa b212 a11-15x (od 315 mm) / max. Spindle bore: hollow clamping device with material passage 102 mm

Extra Information

Control Unit MAZATROL MATRIX NEXUS control system Large 12.1’ LCD color screen User macro (600 variables) EIA-ISO input function Tool path check in the background USB interface (2 pieces) LAN interface Intelligent heat shield Intelligent danger shield Mazak voice support (Voice Adviser) Virtual machining Turret 12-position tool turret Tail Stock Fully programmable tailstock Tailstock pressure regulation: 10 steps Tailstock with running quill MK5

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing