Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

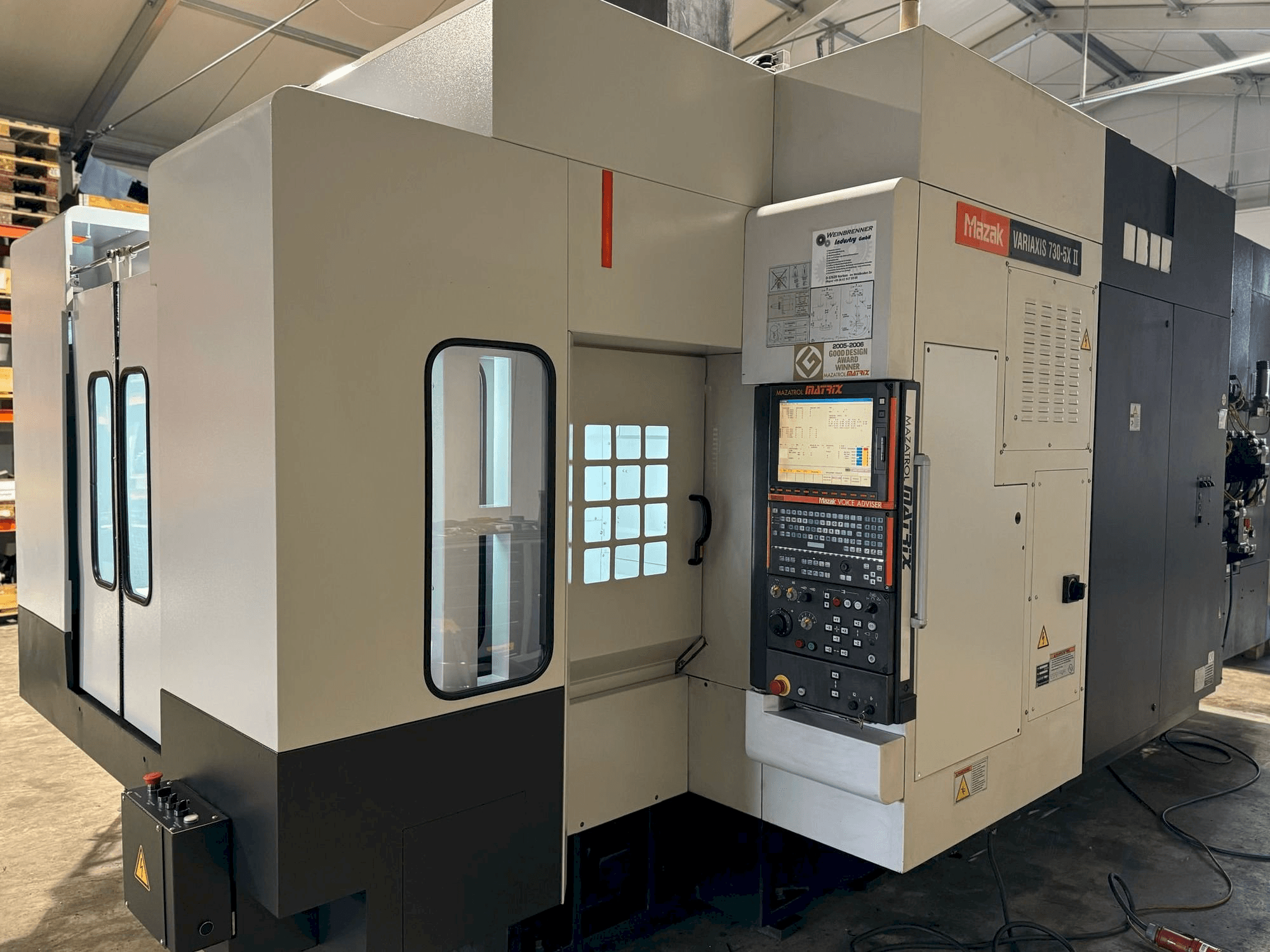

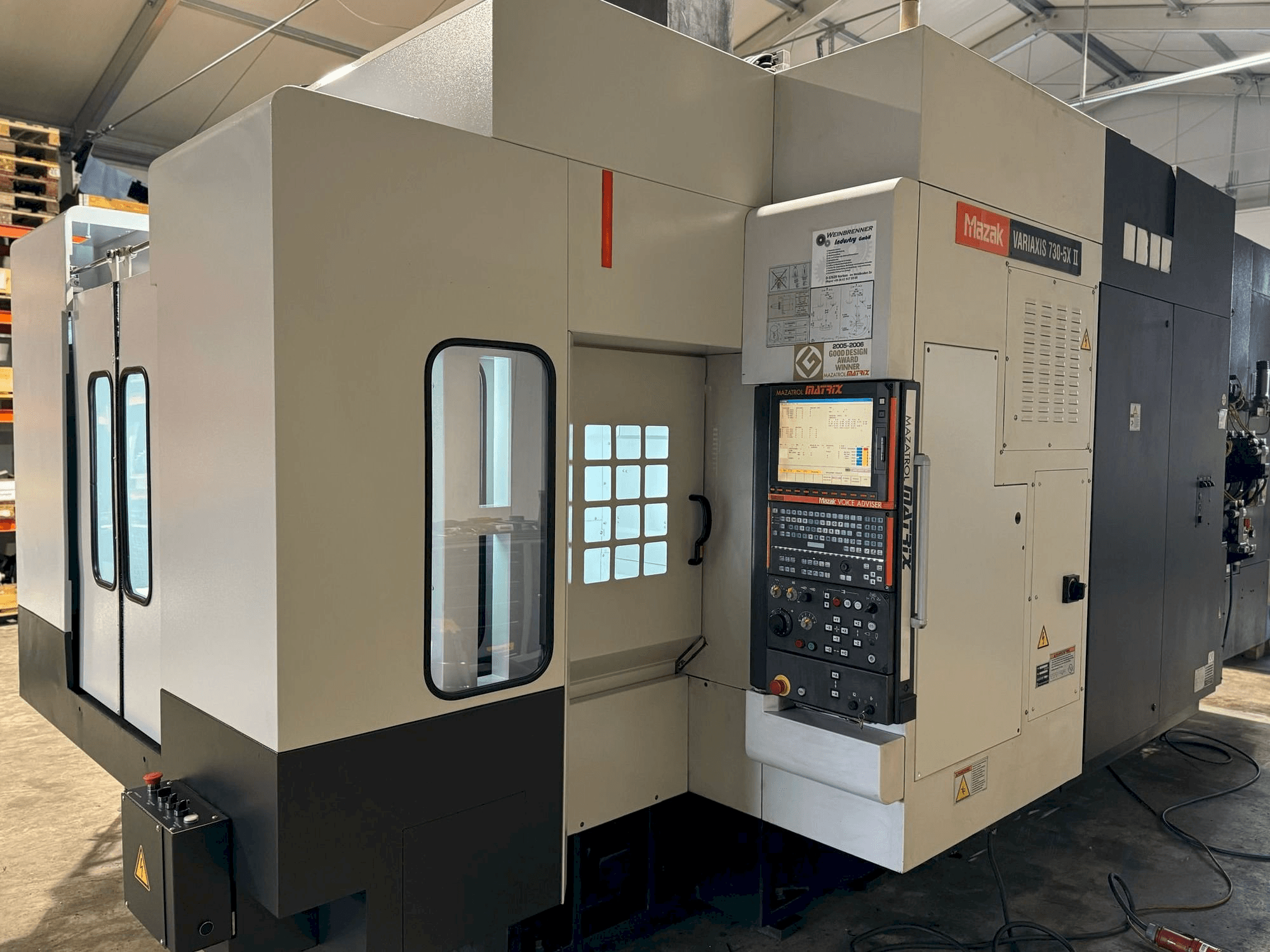

Mazak - Variaxis 730-5X IIDE-MIL-MAZ-2007-00002

Sold

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

Click to chat on WhatsApp

- GINDUMAC

- Products

- Machine Tools

- MAZAK Variaxis 730-5X II Vertical Machining center

This MAZAK Variaxis 730-5X II Vertical Machining center was manufactured in the year 2007. It is equipped with a Mazatrol Matrix control unit and has 5 axis. The machine has a spindle speed of 10000 rpm.

Overview

- brand: Mazak

- year: 2007

- MODEL: Variaxis 730-5X II

- application type: Milling

- Location: Germany

- machine type: Universal Machining Centre

- control unit brand: MAZATROL

Technical Information - Mazak Variaxis 730-5X II

Control Unit

- Control Brand: MAZATROL

- Control Model: Matrix

Dimensions

- Machine Depth: 3907 mm

- Machine Height: 3535 mm

- Machine Weight: 21000 kg

Movement

- A-axis Max: 30°

- A-axis Min: -120°

- C-axis: 360°

- Number of Axes: 5

- X-axis Travel: 730 mm

- Y-axis Travel: 850 mm

- Z-axis Travel: 560 mm

Technical Specification

- Spindle Power: 22 kW

- Spindle Speed: 10000 RPM

Additional Information

Machine Benefits

Qualitative Machine Benefits

- The machine has been partially overhauled, documentation is available. An accuracy protocol was created.

- A laser measurement using renishaw xl 80 was carried out, as well as a quick check using renishaw ball bar. Protocols are available.

- The ball screws of the x and y axes have been replaced.

- All components have been checked, serviced, repaired or defective components replaced.

- The machine has a consep system, which has also been checked and defective components replaced.

- Documentation: oil mist extraction

- Oil mist extraction

Technical Machine Benefits

- Interface fms / robot prepared

- 2 compartment pallet changer

- Automatic pallet door

- Internal cooling ikz 25bar

- Eia

- External cooling

- Chip flushing

- Chip conveyor consep

- Measuring probe 3d renishaw omp60

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Your account manager:

Borja Garcia

Borja Garcia is one of our used machinery trading experts and will be your direct contact for any further questions on the machine. Feel free to contact him/her.

Payment Terms

Payment in advance

Asset Financing