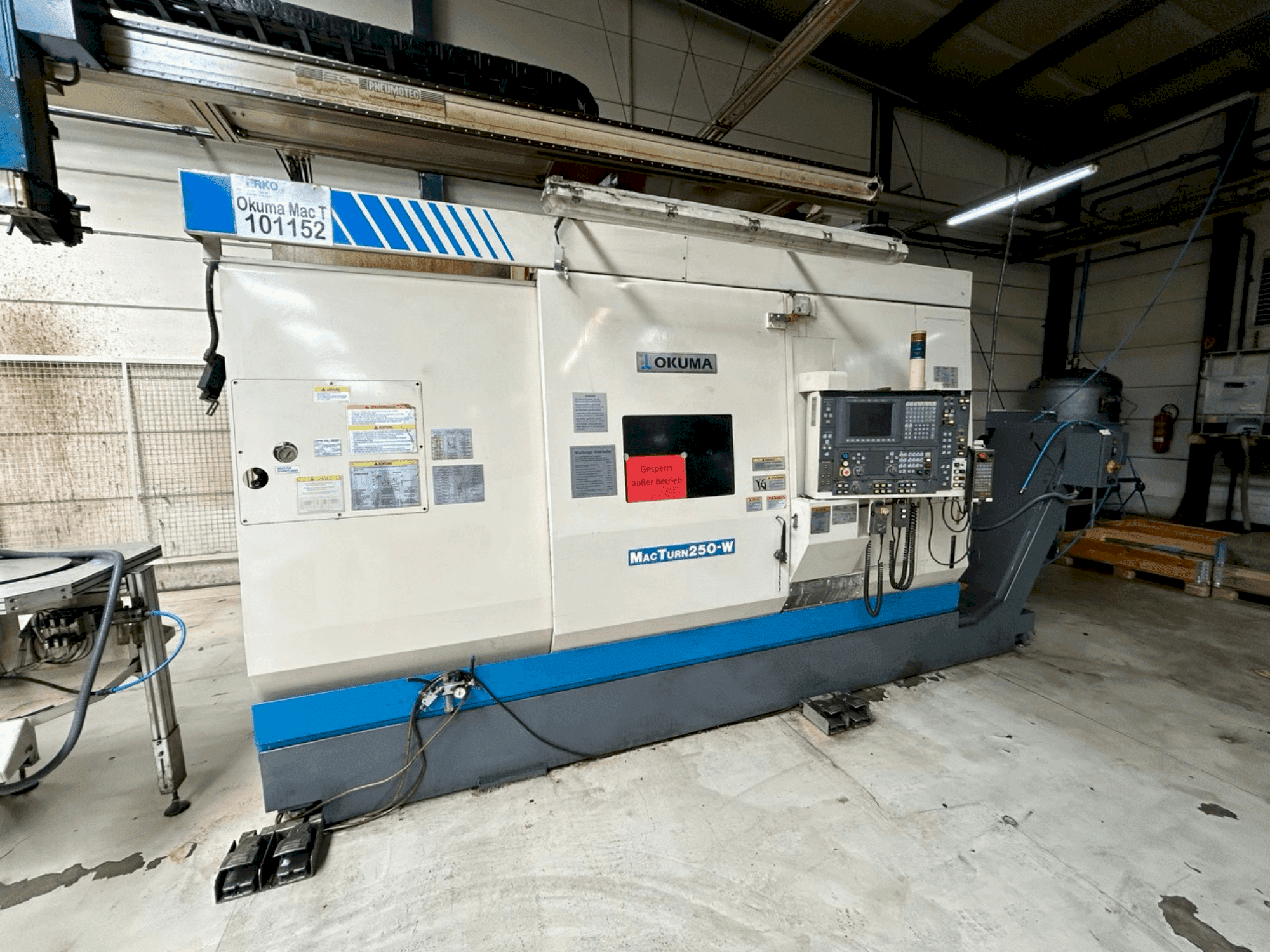

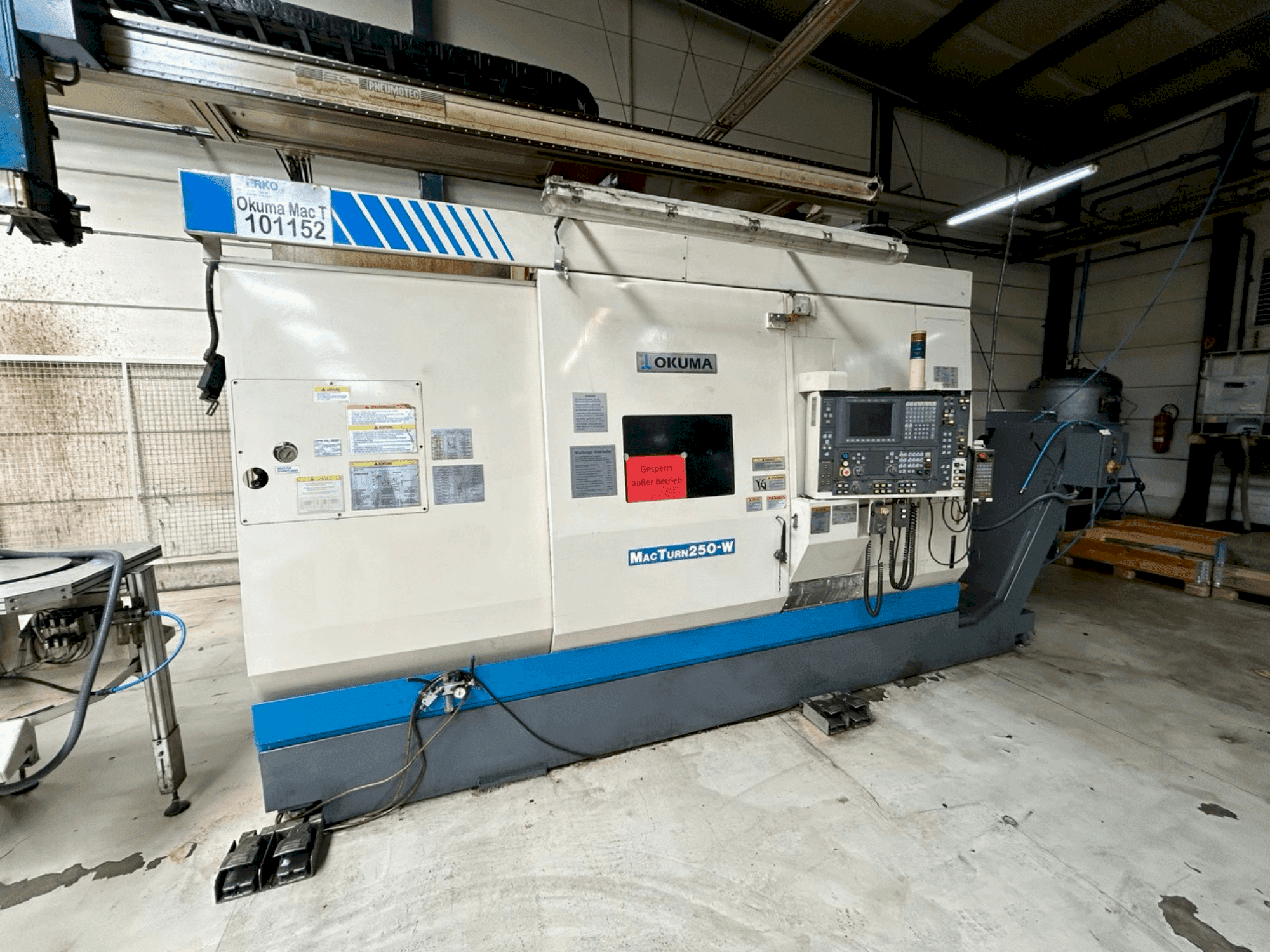

Okuma - Macturn 250WDE-TUR-OKU-2006-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used Okuma Macturn 250W - Lathe For Sale | gindumac.com

This 5-axis Okuma Macturn 250W lathe was manufactured in 2002. It features a swing over saddle of ø550 mm, a maximum machining diameter of ø550 mm, and a maximum work length of 1025 mm. The machine includes a 360-degree C-axis and a B-axis indexing angle of 1 degree. A great opportunity to buy this Okuma Macturn 250W lathe. Reach out for further details regarding this lathe.

Overview

- brand: Okuma

- year: 2006

- MODEL: Macturn 250W

- application type: Turning

- Location: Germany

- machine type: Turn-Mill Centre

Technical Information - Okuma Macturn 250W

Movement

- B-axis Max: 1°

- B-axis Min: 1°

- C-axis: 360°

- X-axis Travel: 475 mm

- Y-axis Travel: 160 mm

- Z-axis Travel: 1170 mm

Technical Specification

- Max. Workpiece Diameter: 550 mm

Additional Information

Machine Benefits

Technical Machine Benefits

Between centers: 1000 mm

Swing over saddle: 550 mm

Extra Information

Machine still under power / machine was delivered new 2006

Control System: The machine was initially planned with the U100L control, but was later changed to the E100L control (including soft- and hardware).

Sub-Spindle as W-Axis: Includes Hollow Clamping Device .

Drive Power: 11 kW for Sub-Spindle.

Milling Spindle (B-Axis):

B-Axis in 0.001-steps.

Tool Holder System: HSK63 (used for various holders).

Tool Changer (ATC): 44 Stations Tool Changer

Lower Turret: 12 Stations Revolver.

System: DIN 69880, Shank 40 mm.

Tool Measuring Device: Automatic swing-in

High-Pressure Cooling System:

Preparation for 70 bar High Pressure .

High-pressure pump 70 bar JHP20/70 (1 unit).

Interface for High Pressure (Kühlmittelhochdruck 70 bar) for various tool holders.

Workpiece Handling:

Handling system for loading and unloading.

Workpiece Catcher, programmable, pneumatic.

Measuring/Monitoring:

In-Process-Measuring System Renishaw.

Automatic Zero Point Shift Z-Axis and C-Axis.

Additional Measuring in Y-Axis

Screw-line Interpolation , also for thread milling.

Programmable tool life (progr. Werkzeugstandzeit) / call up sister tools

Software/Functions:

Free M-Functions M101-M104.

Additional M-Codes M340-M347 and M50-M51.

Software Water/Air through Spindle M50/M51.

Additional accessories and tools acailable.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing