Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

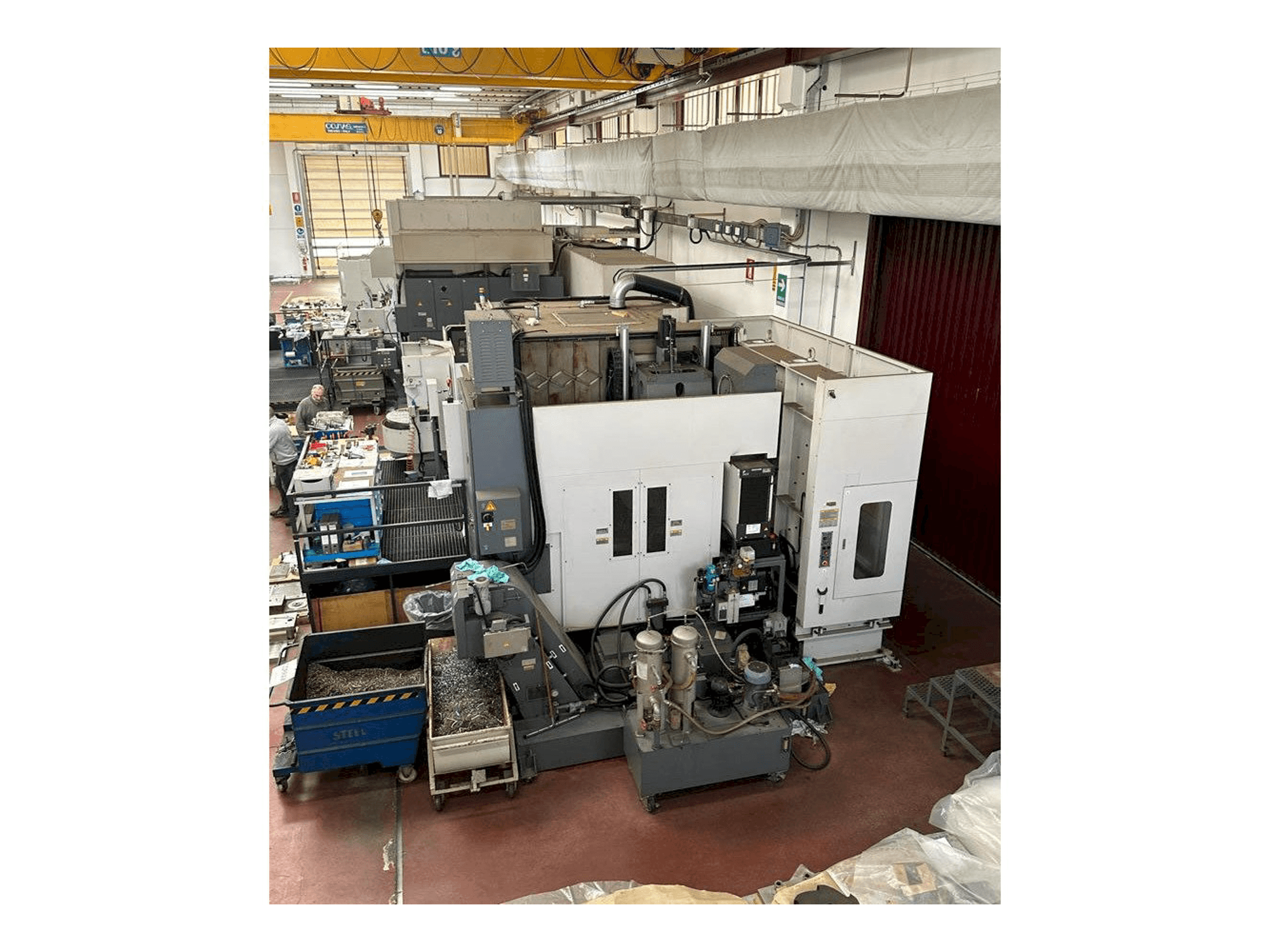

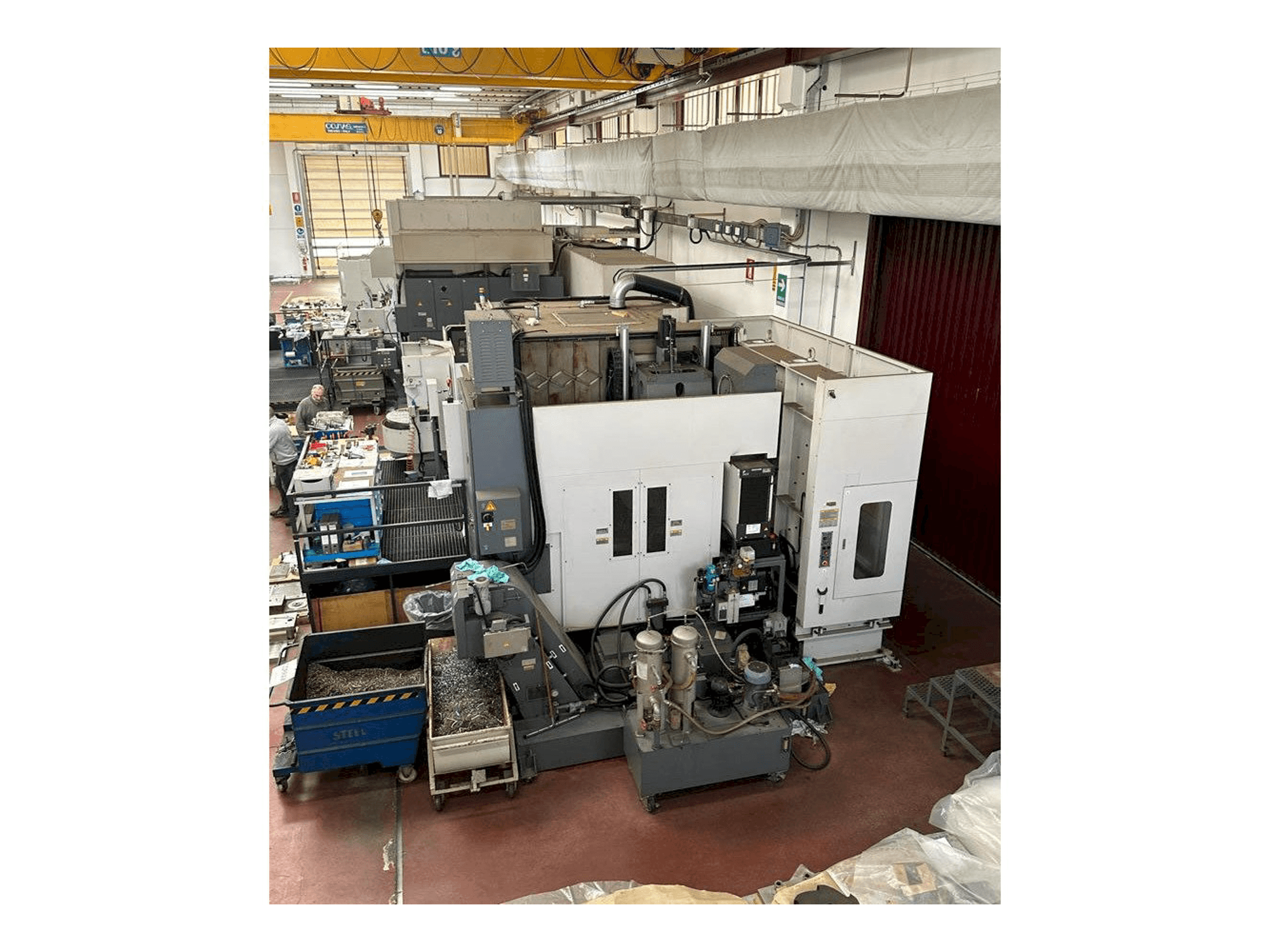

Okuma - MILLAC 800VHIT-MIL-OKU-2009-00001

Sold

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

Click to chat on WhatsApp

- GINDUMAC

- Products

- Machine Tools

- OKUMA MILLAC 800VH Vertical Machining center

This OKUMA MILLAC 800VH Vertical Machining center was manufactured in the year 2009. It is equipped with an Okuma P200 M control unit and has 5 axis. The machine has a spindle speed of 10000 rpm.

Overview

- brand: Okuma

- year: 2009

- MODEL: MILLAC 800VH

- production hours: 8890

- application type: Milling

- Location: Italy

- machine type: Vertical Machining Centre

- control unit brand: OKUMA

Technical Information - Okuma MILLAC 800VH

Control Unit

- Control Brand: OKUMA

- Control Model: OSP P200 M

Dimensions

- Table Length: 800 mm

- Table Load: 1000 kg

- Table Width: 800 mm

Movement

- Number of Axes: 5

- X-axis Travel: 1020 mm

- Y-axis Travel: 1020 mm

- Z-axis Travel: 1020 mm

Technical Specification

- Spindle Power: 18.5 kW

- Spindle Speed: 10000 RPM

Additional Information

Machine Benefits

Qualitative Machine Benefits

- Lubrication system through the spindle center at 70 bar 13/18 lt. /min. (6. 9 mpa) with in-line centrifugal filter

- Air/coolant blow through selectable spindle

- Shower washing system

Technical Machine Benefits

- Automatic palletization at 6 positions including 4 additional pallets

- Tool magazine with 120 positions

- Optical scales on linear axes x, y, z in addition to the std encoders.

- Circular optical scale on spindle tilting head axis with 0. 001 g.

- Resolution with tilting locking by means of brake

- Circular optical scale on rotary table c axis

- Resolution 0. 001 g. With continuous locking by brake

- Measuring probe taken from tool changer for resetting/checking the workpiece including macro b on the cnc

- Air blow for chips cleaning both around the spindle and for cleaning the cone flange bt 50

- Laser probe for checking blum/laser diameter and tool length with pneumatic system for cleaning laser beam lenses

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Your account manager:

Borja Garcia

Borja Garcia is one of our used machinery trading experts and will be your direct contact for any further questions on the machine. Feel free to contact him/her.

Payment Terms

Payment in advance

Asset Financing