Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

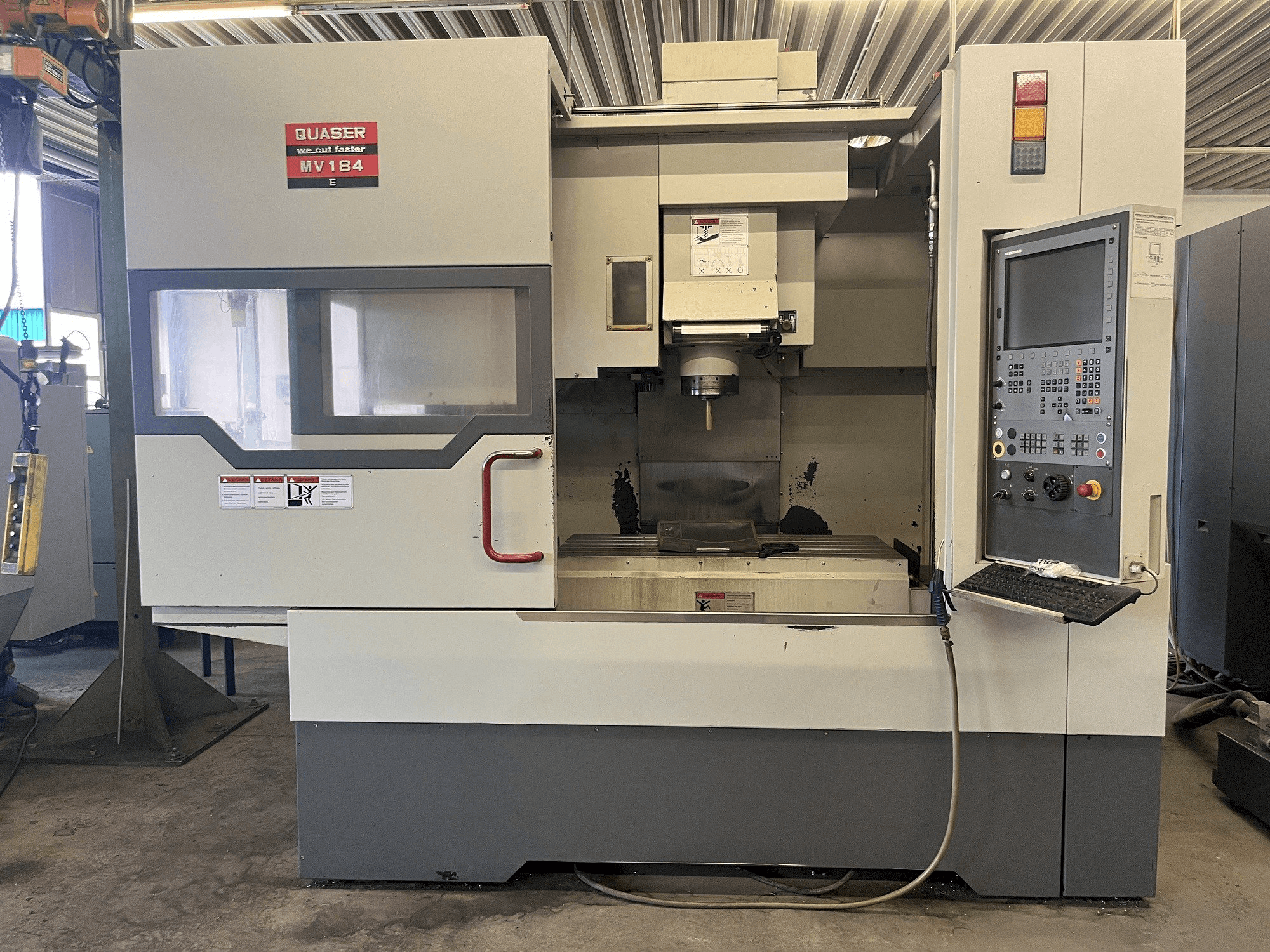

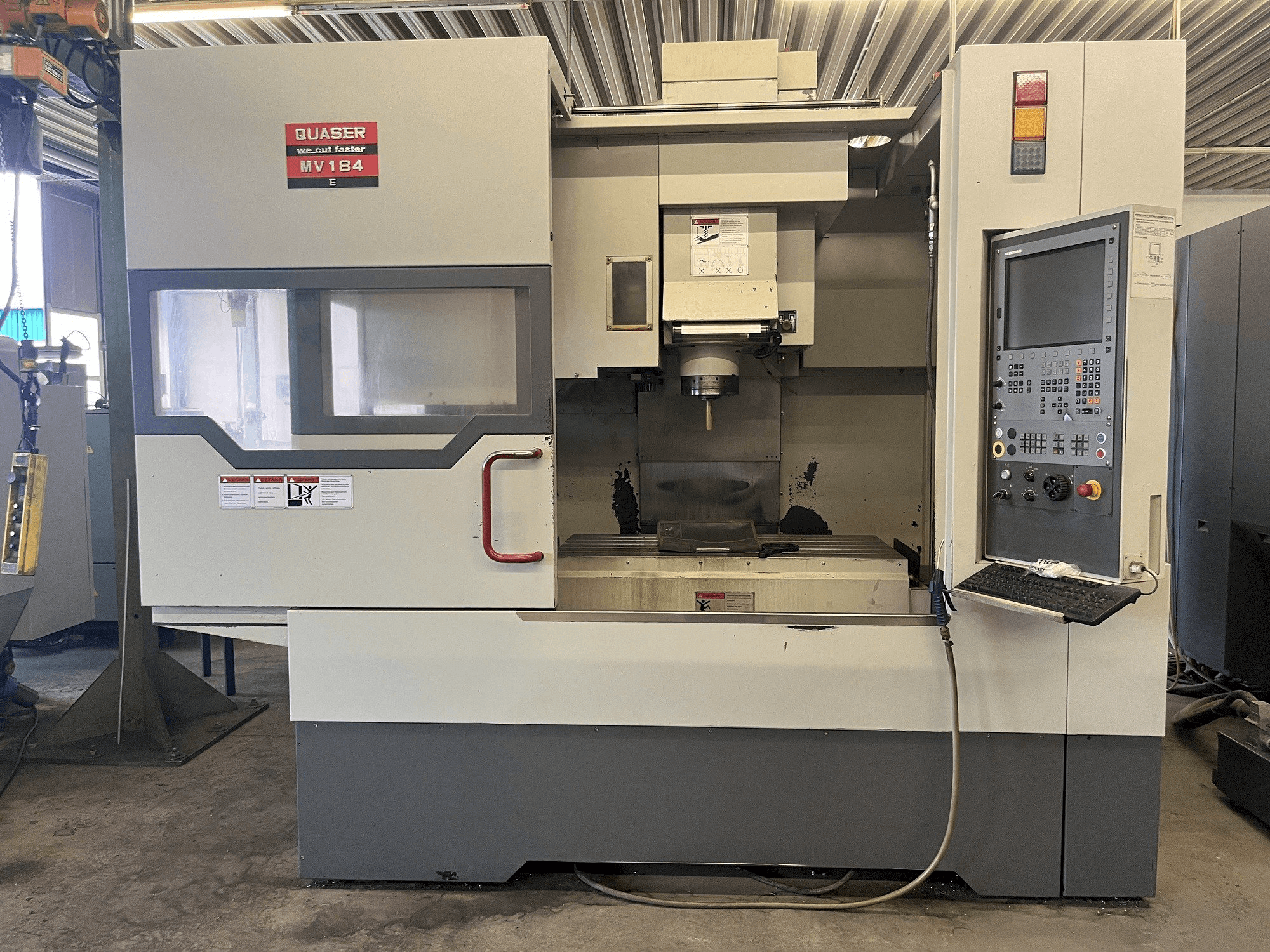

Quaser - MV 184EDE-MIL-QUA-2009-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- Quaser MV 184E Vertical Machine Center

This Quaser MV 184E Vertical Machine Center was manufactured in the year 2009. It is equipped with a Heidenhain iTNC 620 control unit and has 3. The machine has a spindle speed of 30 - 12000 rpm.

Overview

- brand: Quaser

- year: 2009

- MODEL: MV 184E

- application type: Milling

- Location: Germany

- machine type: Vertical Machining Centre

- control unit brand: HEIDENHAIN

Technical Information - Quaser MV 184E

Control Unit

- Control Brand: HEIDENHAIN

- Control Model: iTNC 620

Dimensions

- Machine Depth: 2920 mm

- Machine Height: 2860 mm

- Machine Weight: 6790 kg

- Table Length: 1200 mm

- Table Load: 7 kg

- Table Width: 600 mm

Movement

- Number of Axes: 3

- X-axis Travel: 1020 mm

- Y-axis Travel: 610 mm

- Z-axis Travel: 610 mm

Technical Specification

- Spindle Power: 17 kW

- Spindle Speed: 12000 RPM

Additional Information

Additional equipment

- Chip Conveyor

Machine Benefits

Qualitative Machine Benefits

- Cooling system for main spindle with separate 100 1 oil cooling circuit and air supply for main motor

- Preloaded ball screws diam. 45 mm

- Tool holders according to din 69871 (bt 40 oplion), tool tightening bolts according to din 69872 (iso) 7388 option)

- Chip disposal, consisting of 2 screw conveyors and sptllsyslem in the working area, as well as scraper belt conveyor

- Coolant tank with 300 l capacity

- Flood cooling, with 12 adjustable outlet nozzles located in a ring on the spindle nose, conveying capacity 60 1/min at 2 bar palron filter 80 µ for chip flushing and flood cooling

- Internal coolant supply with grundfoss pump 20 bar. 251/min, incl. Cartridge filter 25 µ

- Chip flushing with grundtoss pump 60 1/min at 2 bar, stainless steel chip trays in the working chamber

- Working chamber full protection with large viewing doors (door opening 900 mm) and 2 working area lights, as well as machine status light

- Blow air, external. For dry processing

Technical Machine Benefits

- Internal coolant supply 20 bar

- Number of tools in the magazine 30 pieces

- Tool holder sk 40

- Double-arm tool changer with 30 storage locations

- Large dimensioned linear guides in all axes

- Highly dynamic digital feed drives with 6800 n (z 13900 n) axis power

- Computer-optimized, heavy machine body made of heavily ribbed cast iron

- Rapid traverse 32 rnlmin (z ;24 mlmin), acceleration {x/y/z) 3/3 /3 m/sec'

- Torque 108 nm

- Siemens-weiss main spindle sk 40, suitable for standard fixtures and tooling with facing system

Extra Information

Coolant spray gun. - two-color painting in light gray/grey. - Glass scales for X-. Y- and Z-axis (HDH) including overpressurization to prevent contamination of the direct measuring system. - Automatic central lubrication for the ball screws. - Quaser machining centers comply with CE standards.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing