SAACKE - UWIFCH-GRI-SAA-2008-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used SAACKE UWIF For Sale | gindumac.com

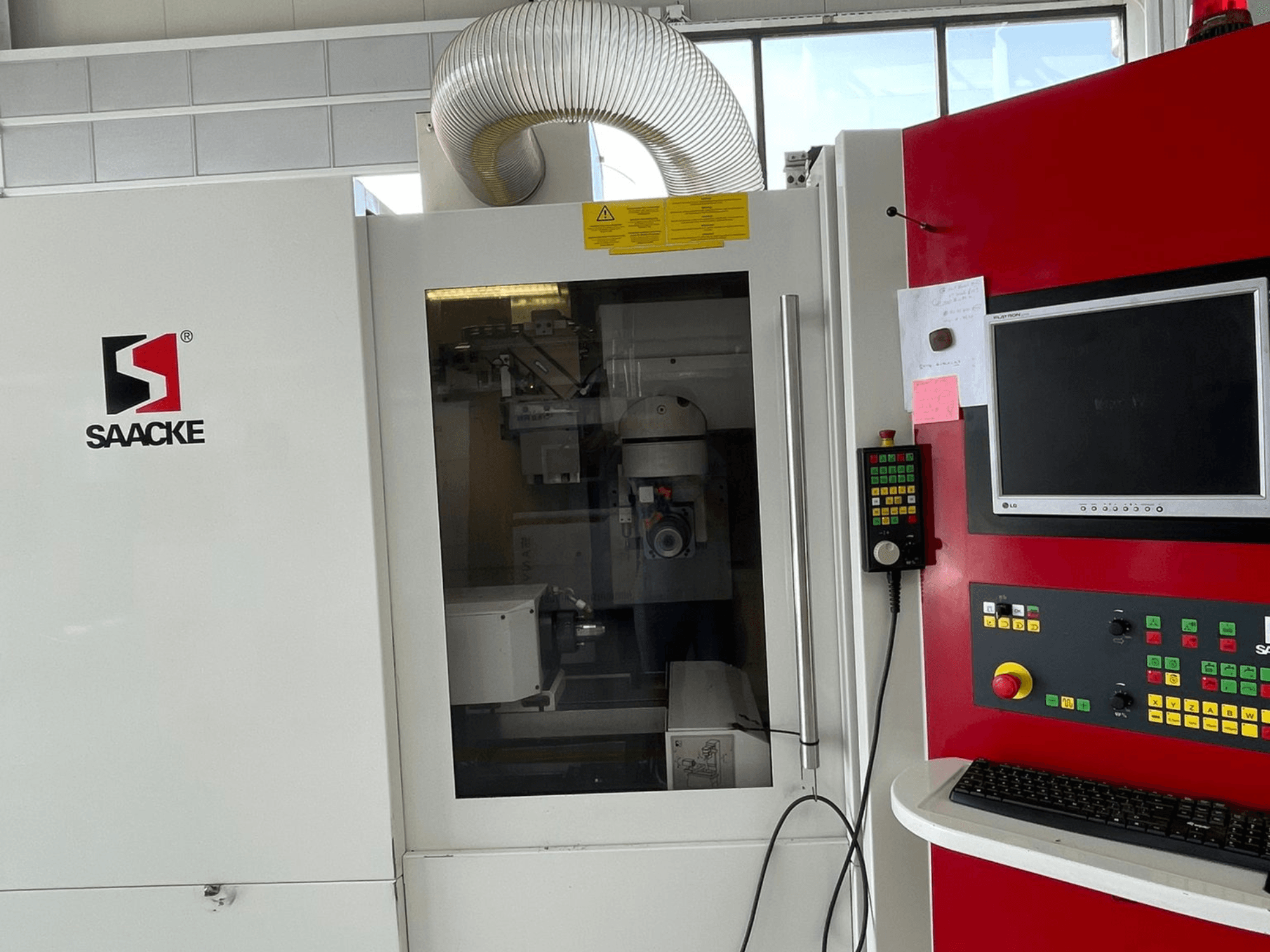

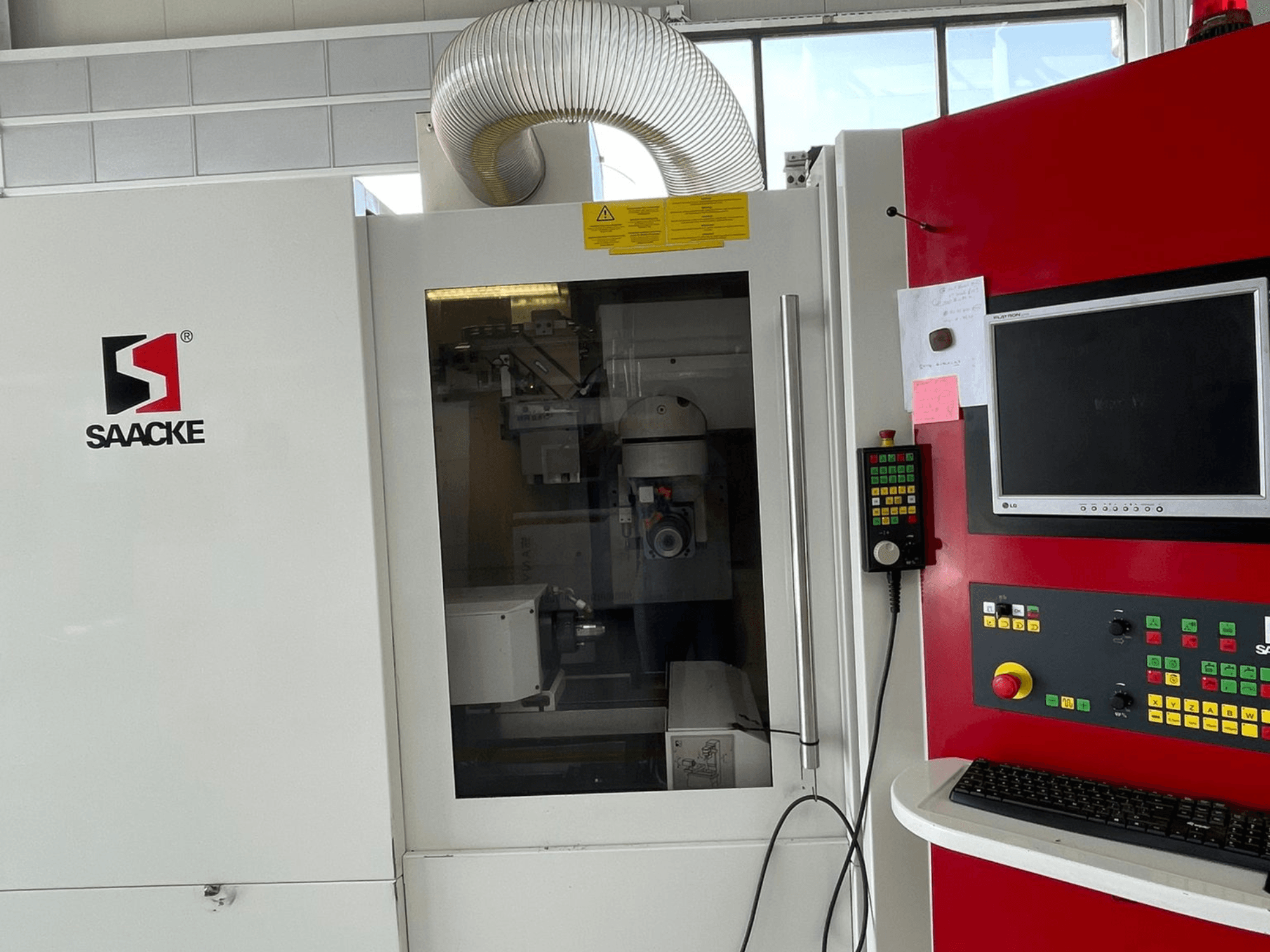

This 5s SAACKE UWIF cylindrical grinding machine was manufactured in 2008. It features a maximum spindle speed of 600 rpm and a powerful grinding spindle peak power of 16 kW. The machine supports a variety of workpiece sizes, with a maximum diameter of Ø 20 mm and a weight capacity of 1 kg. If you are looking to get high-quality grinding capabilities, consider the SAACKE UWIF cylindrical grinding machine we have for sale. Contact us for further details.

Overview

- brand: SAACKE

- year: 2008

- MODEL: UWIF

- application type: Grinding

- Location: Switzerland

- machine type: Cylindrical Grinding Machine

Technical Information - SAACKE UWIF

Dimensions

- Machine Weight: 3800 kg

Movement

- Number of Axes: 5

Technical Specification

- Spindle Speed: 600 RPM

Additional Information

Workpiece carrier A-axis: Direct drive/hollow shaft motor; indexing accuracy ±15"; indexing possibilities 1–999; cumulative pitch error at 100 mm: 8 µm; speed max. 600 rpm

Tool holder: ISO 50

Spindle clearance holding sleeve: max. 28 mm (with automatic clamping: Ø20 mm)

Nominal drive power:

Grinding spindle S1-100%: 7.5 kW; peak: 16 kW

X-axis longitudinal travel: 2 kW

A-axis workpiece carrier: 2 kW

Z-axis cross slide: 2 kW

Y-axis grinding head slide height: 2 kW

B-axis grinding head rotation (rotary table): 2 kW

Position measuring systems:

A-axis: Direct measuring system

B-, X-, Y-, Z-axis: Indirect measuring system

Resolution X/Y/Z: 0.0001 mm (0.1 µm)

Resolution A/B: 0.0001°

Electrical connection: 20 kW / 50 A; operating voltage 400 V, 50 Hz; control voltage 24 V; lighting voltage 230 V; backup fuse: separate supply from mains

Compressed air: 15–17 Nm³/h; pressure min/max 6/8 bar (600/800 kPa); quality ≥ Class 4 (ISO 8573-1)

Control & software: CNC NUM Axium Power 1050 with PC, program memory 512 k; NUMROTOplus software (dongle/hardlock required); zero points calibrated using enclosed measuring instructions (no marked reference points)

Additional equipment

Workpiece changer options (automation):

Option 1: Pick-up design

Max. workpiece: Ø20 mm × 120 mm; 1 kg

Capacity per pallet:

Ø3.0–5.0 mm shank: 40 pcs

Ø5.1–8.0 mm: 32 pcs

Ø8.1–11.0 mm: 28 pcs

Ø11.1–14.0 mm: 24 pcs

Ø14.1–20.0 mm: 20 pcs

Option 2: Chain loader magazine (with gripper unit)

Capacity: 64 workpieces

Max. workpiece: Ø32 mm × 200 mm; 2.5 kg

Features: Chaotic loading of different workpieces; automatic changing of collets possible

Holding sleeves: Ø6, 8, 10, 12, 14, 16, 20

External chain loader option: increases machine weight to approx. 3,800 kg and space to 3,000 mm × 1,875 mm

Coolant filter system (TRANSOR): To be provided by customer; air for backwashing approx. 700 Nl/min for 5 min every 6–9 hours

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing