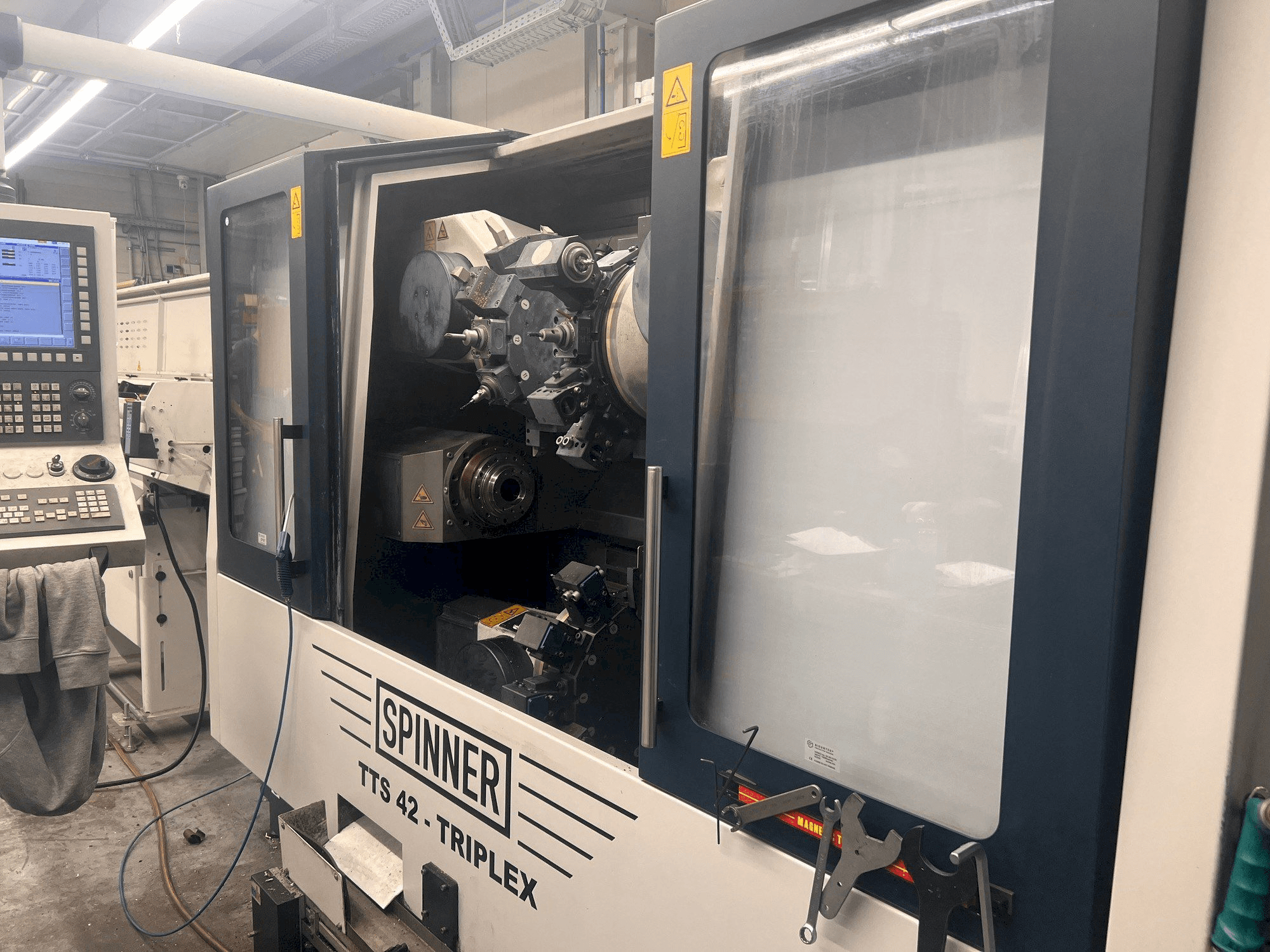

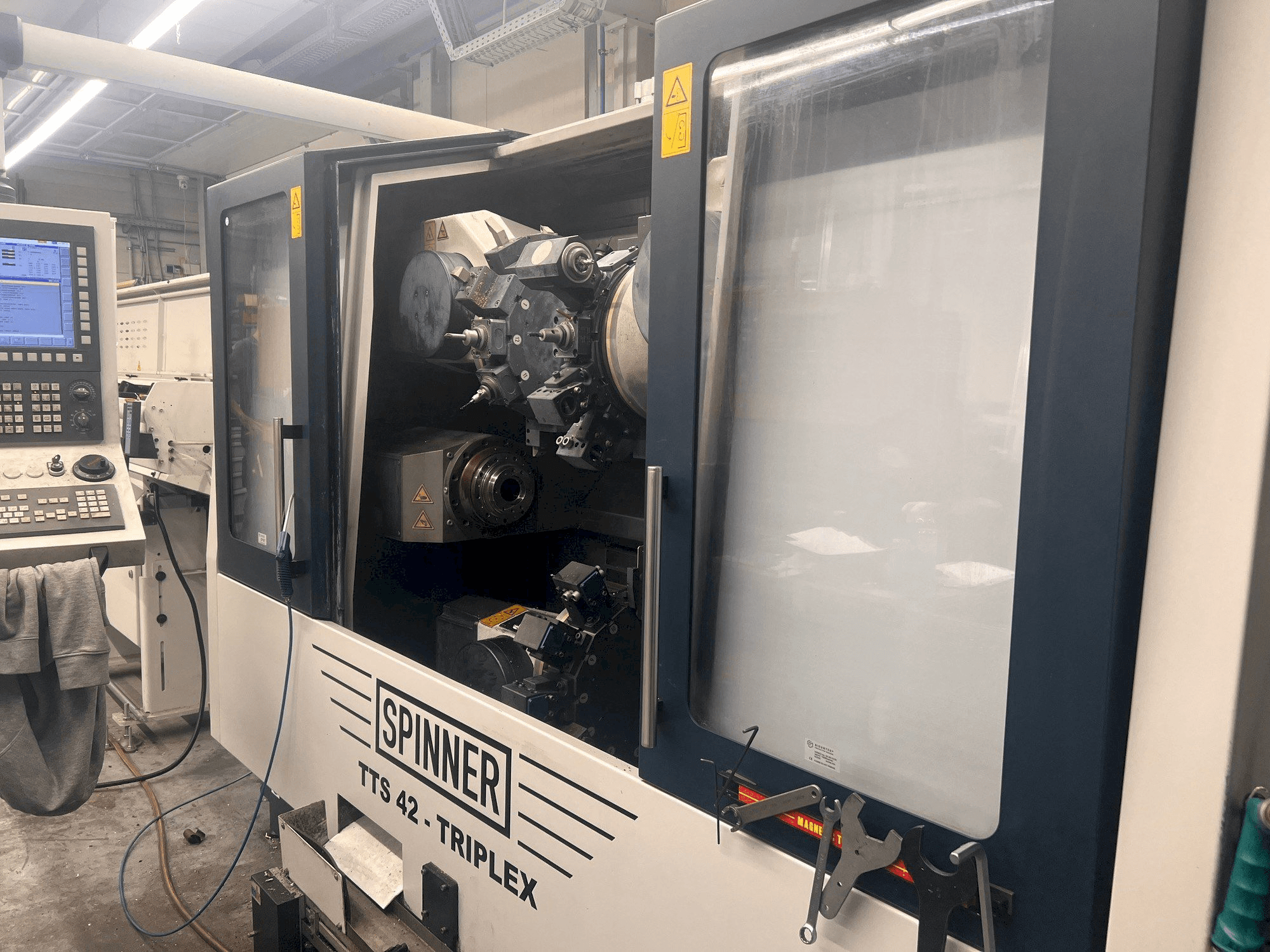

SPINNER - TTS 42DE-TUR-SPI-2020-00001

99,000 €

gindumac price

(Ex works)

get an official quote

Visit the machine

make a counteroffer

Download PDF

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

Click to chat on WhatsApp

- GINDUMAC

- Products

- Machine Tools

- SPINNER TTS 42 Lathe

This SPINNER TTS 42 Lathe was manufactured in the year 2020 in Germany and has 25585 production hours. It is equipped with a Fanuc Series 31i-MODEL B control unit. The machine has a spindle speed of 7000 rpm. See tech specs file as PDF (German) attached for more details.

Overview

- brand: SPINNER

- year: 2020

- MODEL: TTS 42

- production hours: 25585

- application type: Turning

- Location: Germany

- machine type: Horizontal Turning Machine

- control unit brand: FANUC

Technical Information - SPINNER TTS 42

Control Unit

- Control Brand: FANUC

- Control Model: Series 31i-MODEL B

Technical Specification

- Spindle Speed: 7000 RPM

Additional Information

Machine Benefits

Qualitative Machine Benefits

- Unimag interface for bar loading magazines

- Parts conveyor belt

- Spinner bar loading machine type servo. Make spinner, for spindles up to 42mm passage, for material d=4-42mm, length up to 3,200 mm

- 10x external turning holder

- 12x boring bar holders d=32

- 3x recessed boring bar holders

- 6x straight agw

- 3x axial agw

- Material processed so far: aluminum, brass

Technical Machine Benefits

- Spindle 2 (counter spindle) in version up to 7,000 rpm - 42mm

- Revolver 1 : 12-fold with cnc servo drive revolver 2 : 12-speed with cnc servo drive revolver 3 : 12-speed with cnc servo drive dmjgmx

- Ejector unit integrated in counter spindle for ejecting parts into the parts catcher

- Signal lamp on top of machine in three colors red/yellow/green as status display

- Late conveyor as hinged belt conveyor exiting to the right, incl. Integrated coolant tank and return pump

- Coolant system as additional tank incl. Submersible pump 80l/4bar, high-pressure pump up to 80bar / 19. 5l/min

- Flushing gun in the work area

- Holder for messtaster on the machine bed as preparation for the use of a

- Messtaster for tool measurement switching in 3 axes.

- Extraction d=200 to the working area for connection to extraction system

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Your account manager:

Borja Garcia

Borja Garcia is one of our used machinery trading experts and will be your direct contact for any further questions on the machine. Feel free to contact him/her.

Payment Terms

Payment in advance

Asset Financing