Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

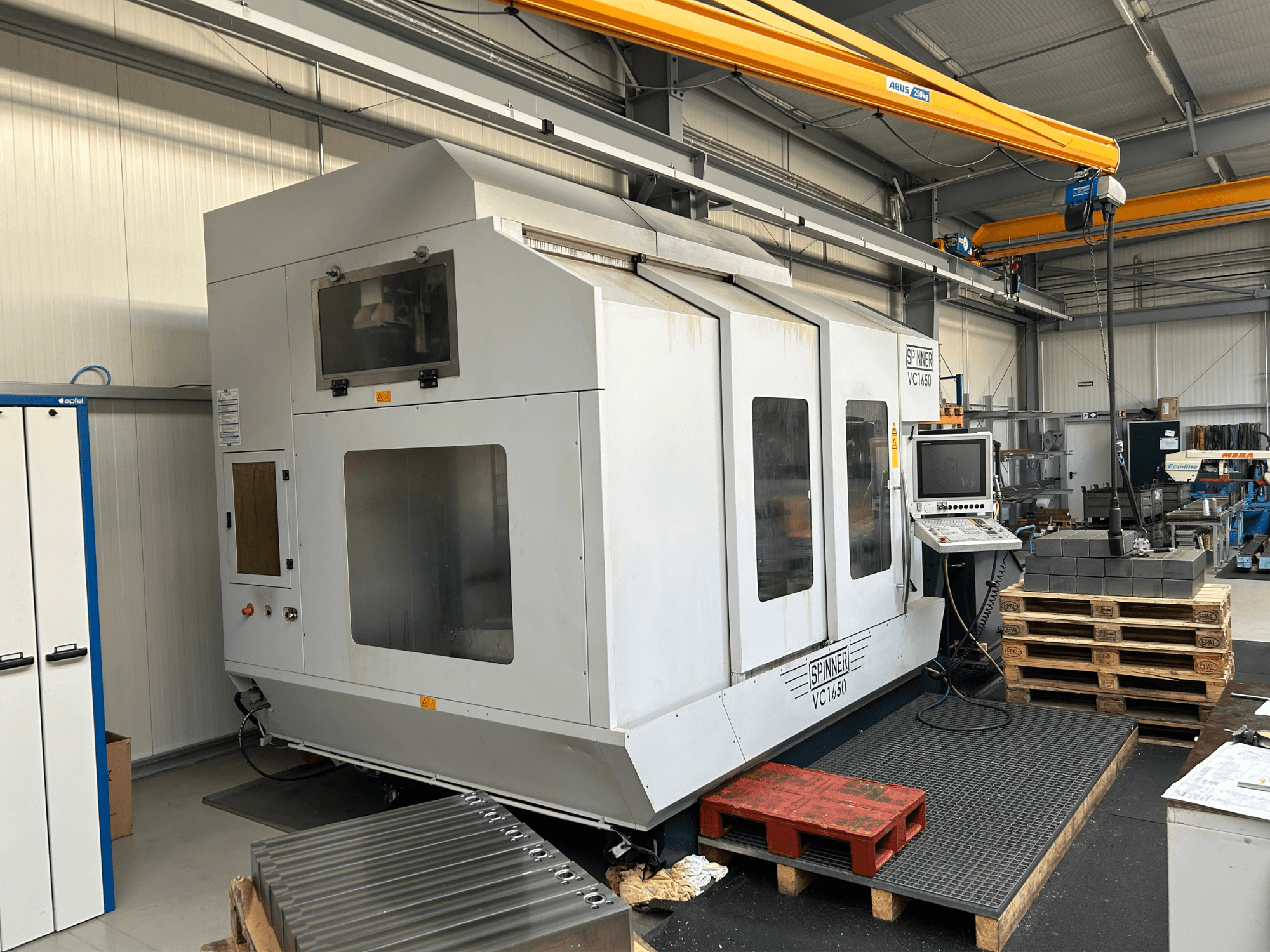

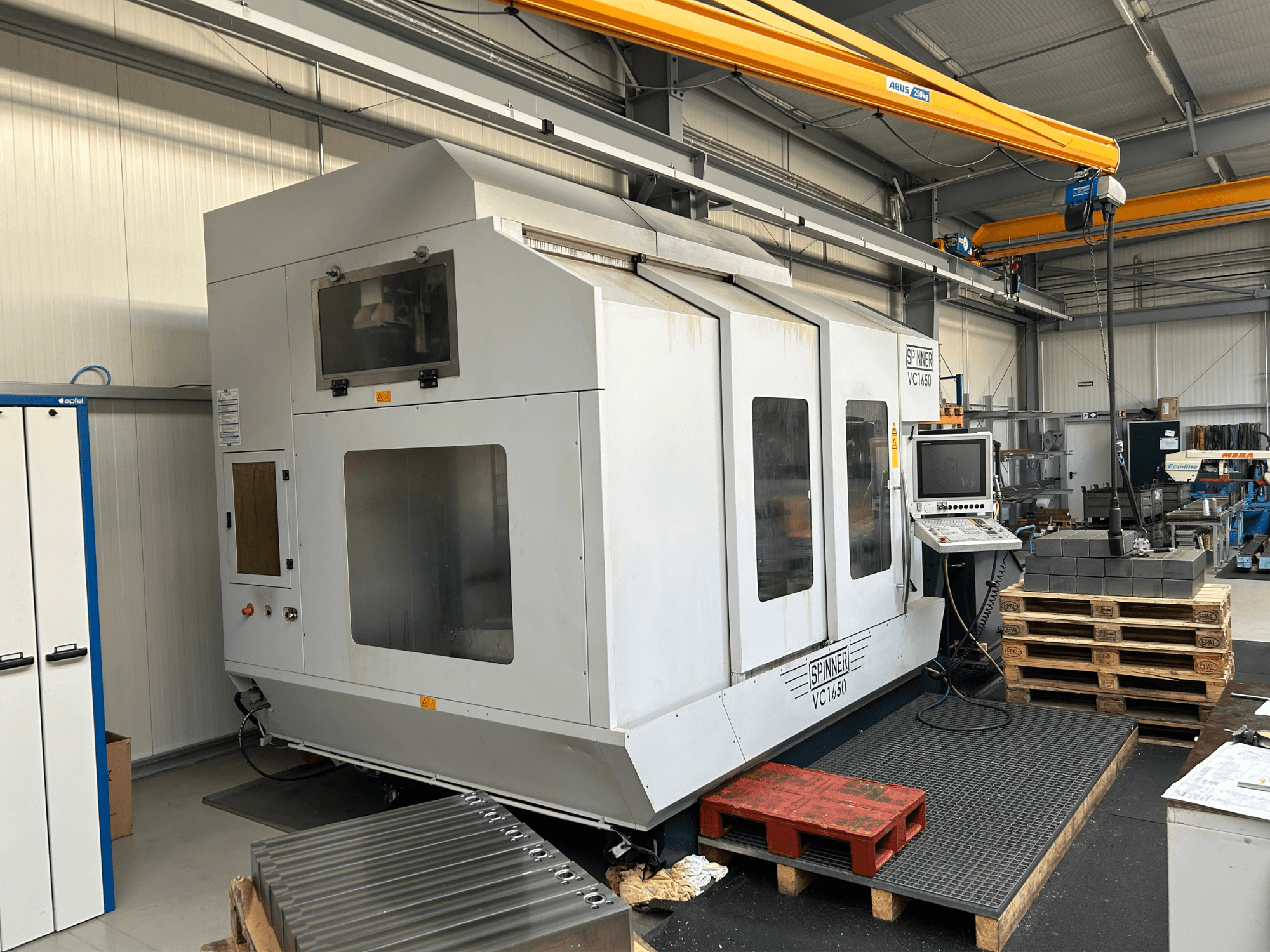

SPINNER - VC 1650-5A-9DE-MIL-SPI-2018-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used SPINNER VC 1650-5A-9 For Sale | gindumac.com

This 5-axis SPINNER VC 1650-5A-9 was manufactured in 2018, featuring a dynamic motor spindle up to 9,000 rpm, HIGH-TORQUE version, and Heidenhain TNC640 control. It includes a 360° rotary table, additional clamping table, and an automatic tool changer for 96 tools. Ideal for complex 5-axis simultaneous interpolation and precision machining. If you are looking to get high-quality milling capabilities consider the SPINNER VC 1650-5A-9 machine we have for sale. Contact us for more information.

Overview

- brand: SPINNER

- year: 2018

- MODEL: VC 1650-5A-9

- production hours: 6000

- application type: Milling

- Location: Germany

- machine type: Vertical Machining Centre

- control unit brand: HEIDENHAIN

Technical Information - SPINNER VC 1650-5A-9

Control Unit

- Control Brand: HEIDENHAIN

- Control Model: TNC 640

Additional Information

Workpiece touch probe: Blum TC52 system with wireless connection for probing workpieces and determining zero point offsets or dimensions

360° rotary table: Diameter 900 mm - 870x870 mm on the left

Additional clamping table on the right: 650x870 mm

Automatic tool changer on the left side for 96 tools

Maximum tool length: 400 mm

Maximum tool diameter: 120 mm (150 mm with adjacent positions free)

Maximum tool weight: 15 kg

Dynamic motor spindle speed: 9000 rpm

High-torque version: 464 Nm (S6 25%); Power: 35KW/68KW (S1/S6)

Travels: X=1650 mm, Y=820 mm, Z=820 mm

Blow-out cleaning for the spindle head

High-pressure flushing: 70 bar TW with an additional 350-liter coolant tank, high-pressure pump, and gravity paper filter

5-axis precision machining center

Automatic kinematic measurement with probe cycles

Functions for three-dimensional tool correction and improved workpiece surface quality

Tool holder must be ordered separately

Two-tone paint finish RAL 7035/5008

Required leveling elements on the machine bed

Around 14.000 on hours

Around 6000 spindle hours

TNC 620/TNC 640 Heidenhain software option with the following functions:

- Automatic measurement and compensation of rotary axes using end-user touch probe cycles

- The kinematic values measured by the cycle are automatically transferred to the machine parameters

- Automatic generation of a log file for evaluating the kinematic measurement - Optimization of machine accuracy during swivel and 5-axis machining

- Workpiece touch probe and calibration sphere are required for measurement

TNC software option: 5-axis simultaneous interpolation and 3D machining

TNC 620/TNC 640 Heidenhain software option; "Advanced Function Set 2"

with the following functions: - 5-axis simultaneous interpolation

- Maintain tool tip position during swivel axis movement through compensating linear axis movements

TCPM function with extended settings for TCPM operation

- Functions for three-dimensional tool correction

- Functions for improving workpiece surface quality

3D model VC1650HV (5-axis version)

for CAD/CAM in STEP format;

Data supplied on CD-ROM; including setup plan and simulation model

Interface preparation for Blum infrared probes TC50/TC52/TC54-20

Receiver unit IC56 and evaluation electronics IF59 installed in the machine for connecting Blum workpieces or

tool probes. The interface can manage up to two touch probe systems simultaneously, meaning that when a workpiece and tool probe are installed at the same time, this position is only required once.

Workpiece probe for milling machines, Blum TC52 system

for insertion into the spindle with wireless connection to the CNC control for probing workpieces and determining zero point displacements or workpiece dimensions

WITHOUT tool holder. Tool holder must be ordered separately.

WITH 1 probe arm 3x30mm.

NEW VERSION 2 with IR receiver IC56

SK50 tool holder for TC52 touch probe

Performance machining center SPINNER VC1850-SA-3 (8K50)/ Heidenhain TNC640

5-axis premium machining center with

360° rotary table, 870 x 870 mm, on the left side of the work area

Sustainable clamping table on the right side of the work area, 660 x 870 mm

Swivel axis at the top of the milling head +11-110°

with Heidenhain TNOS40/19 control

Dynamic motor spindle up to 9,000 rpm: HIGH-TORQUE VERSION HT: M-464 Nm (88 25%); P436 kW/68 kW (81/86)

Travel X1050 mm Y=20mm 2-820mm

Tool taper size 50 according to DIN 6871-A. Drawbars according to DIN 60872-A. Blowout device for spindle taper. Automatic tool changer integrated on the left side of the machine for 96 tools.

Changer slide for changing into the horizontal spindle.

Maximum tool length 400mm; maximum tool diameter 120mm or 150mm with free-standing tools, max. 15kg.

Linear guide in all three axes.

Required adjustment elements on the machine bed for leveling. Full protective enclosure + work area light.

Documentation: Single-color paint finish, two-tone RAL 70355006.

Chip conveyor VC1850 version A2-right TR

At the front under the machine. To the right. Exiting,

Includes two integrated screw conveyors for transporting chips from the work area to the chip conveyor.

Direct measuring systems in X/Y/Z for VC1650-TNC620/TNC640

for model VC1650 VC series with Heidenhain control

centrally mounted between the guideways for optimal accuracy

recommended for high-precision machining and reduced temperature drift

Electrical preparation HD 70 bar

for high-pressure flushing 70 bar.

This position is necessary for installing the high-pressure tank/high-pressure flushing system.

High-pressure flushing 70 bar TW (auxiliary tank) V2 350 liters

additional coolant tank with MTS20-80 high-pressure pump and gravity paper filter

capacitive level switch

For milling machines, spindle-side preparation for coolant feed-through (item 11069P) is required

TANK VOLUME approx. 350 liters

Extraction port 250

Connection flange for electrostatic air purifier, diameter 250T

NC software option "Swivel of the machining plane and rotary table machining"

- Projection of a contour programmed in the XY plane onto the cylinder shell

- Automatic calculation of the feed rate in mm/min of a rotary axis, depending on the distance of the tool to the

rotary axis center

Circle in 3 axes with rotated machining plane (roughing circle)

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Documents

Borja Garcia

Payment Terms

Payment in advance

Asset Financing