Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

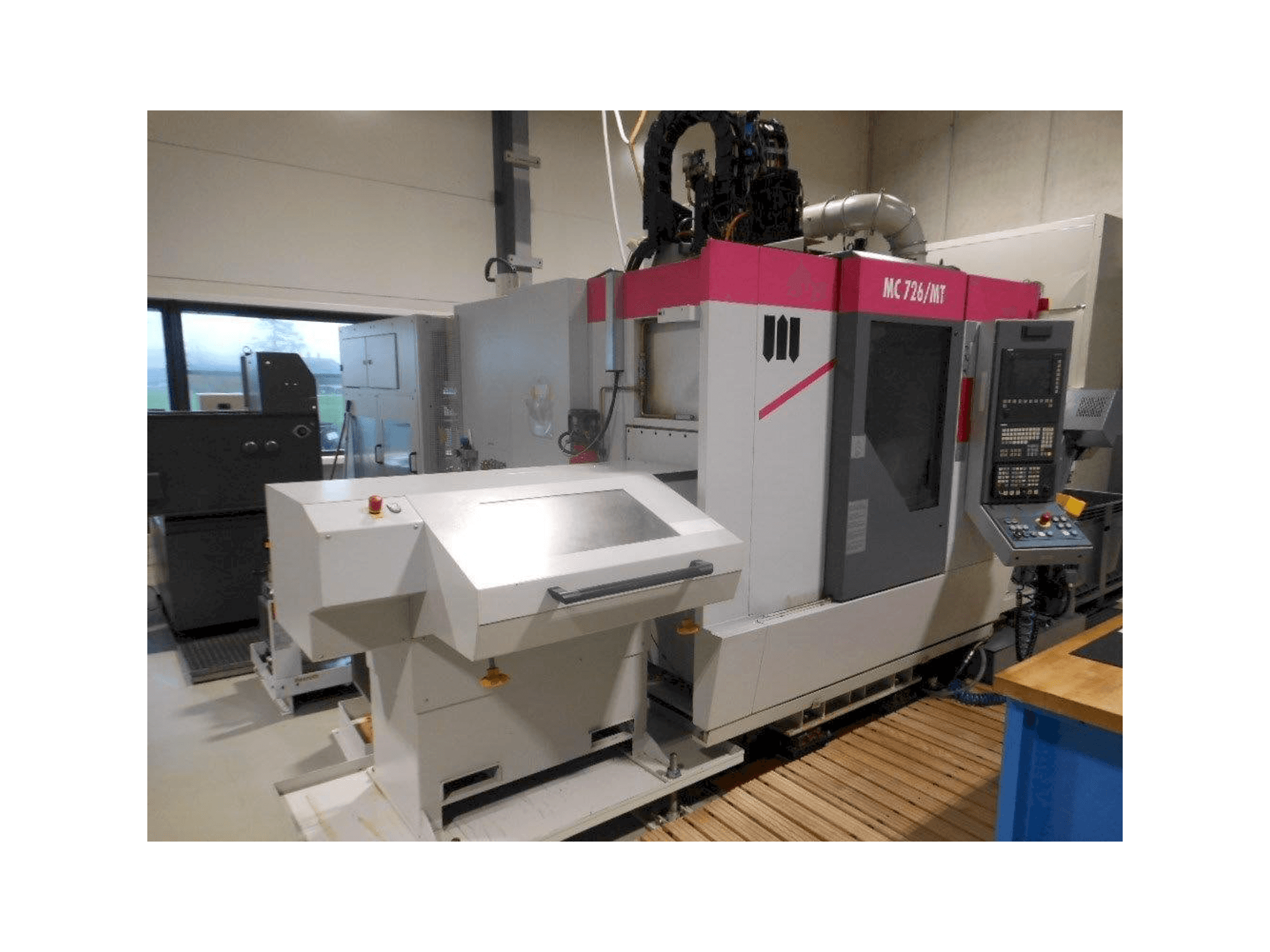

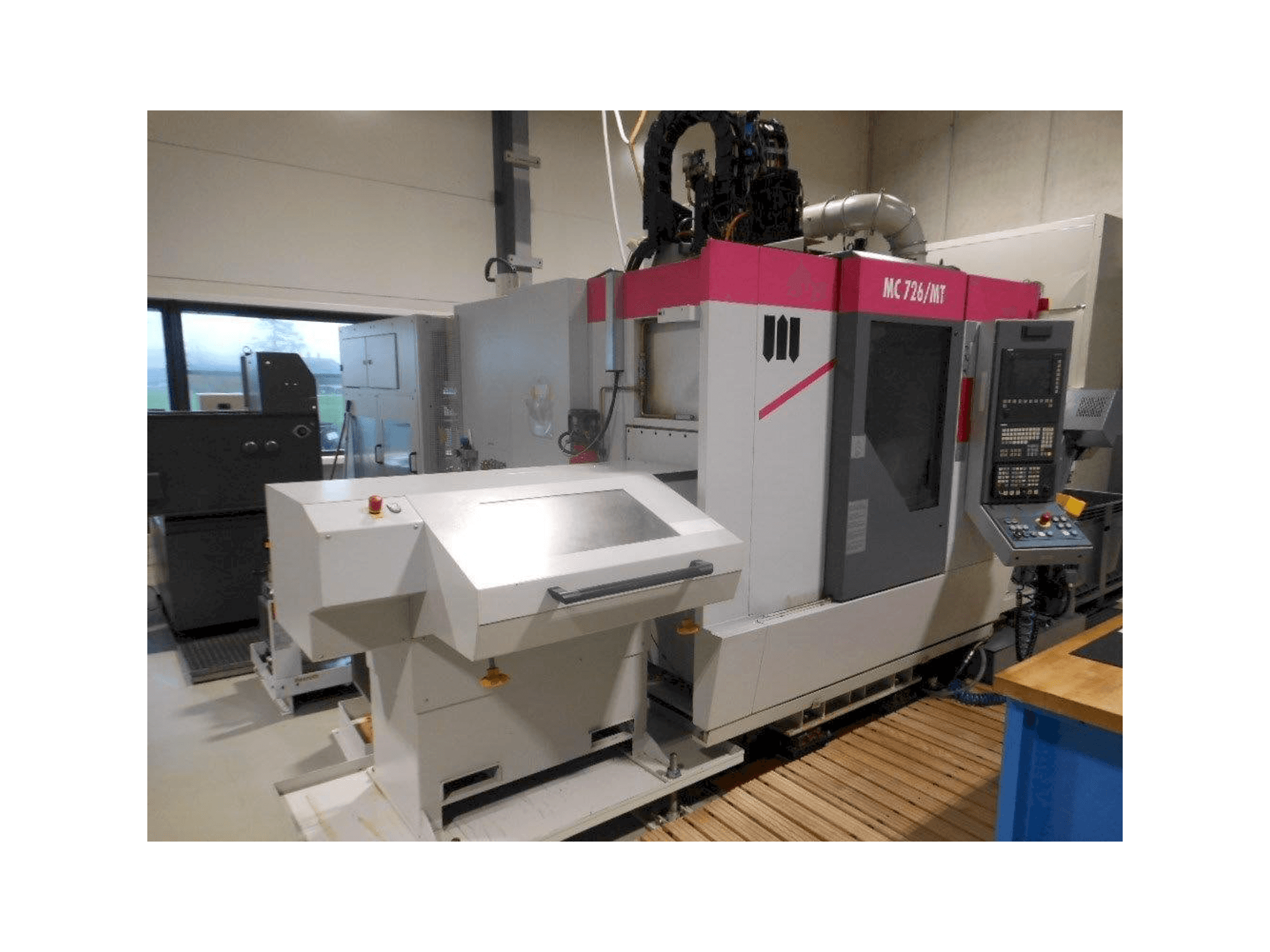

STAMA - MC 726CH-TUR-STA-2006-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- STAMA MC 726

This STAMA MC 726 multitasking lathe milling-turning center was manufactured in Germany in the year 2006. This 7 axis machine is operated through a SIEMENS SINUMERIK control unit. It works with a spindle speed range 36-12000 rpm. This machine includes several options and additional equipment as a 3D probe and a bar feeder. Its PCU was changed and it had a major maintenance in 2018.

Overview

- brand: STAMA

- year: 2006

- MODEL: MC 726

- application type: Milling

- Location: Switzerland

- machine type: Horizontal Machining Centre

- control unit brand: SIEMENS

Technical Information - STAMA MC 726

Control Unit

- Control Brand: SIEMENS

- Control Model: SINUMERIK

Dimensions

- Machine Depth: 7200 mm

- Machine Height: 3300 mm

- Machine Weight: 7000 kg

Movement

- Number of Axes: 7

- X-axis Travel: 500 mm

- Y-axis Travel: 380 mm

- Z-axis Travel: 360 mm

Technical Specification

- Spindle Speed: 12000 RPM

Additional Information

Additional equipment

- 3D probe

- Bar feeder 1m

- Blum laser

- Additional magazine

- Hainbuch chuck and various collets

Machine Benefits

Qualitative Machine Benefits

- Major maintenance in 2018

- Service of the hydraulic unit

Technical Machine Benefits

- Spindle bearing 65 mm

- Max. Torque 45 nm

- Pcu changed in 2018

- New cooling unit for control cabinet

- Baluff system for tool data / holder data

- Artis breakage monitoring

- Oil extraction

- Extinguishing system from kraft&bauer

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Documents

Borja Garcia

Payment Terms

Payment in advance

Asset Financing