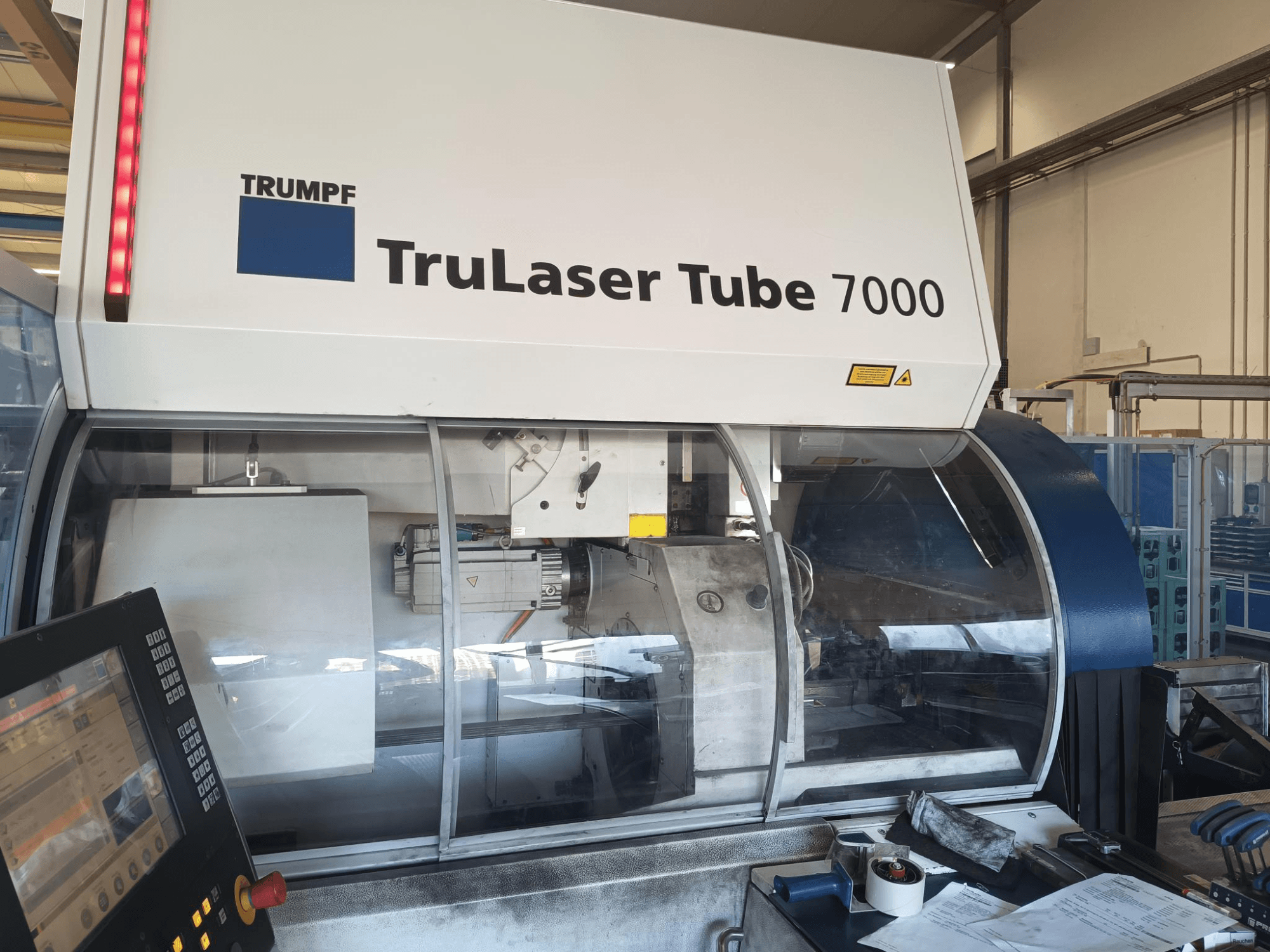

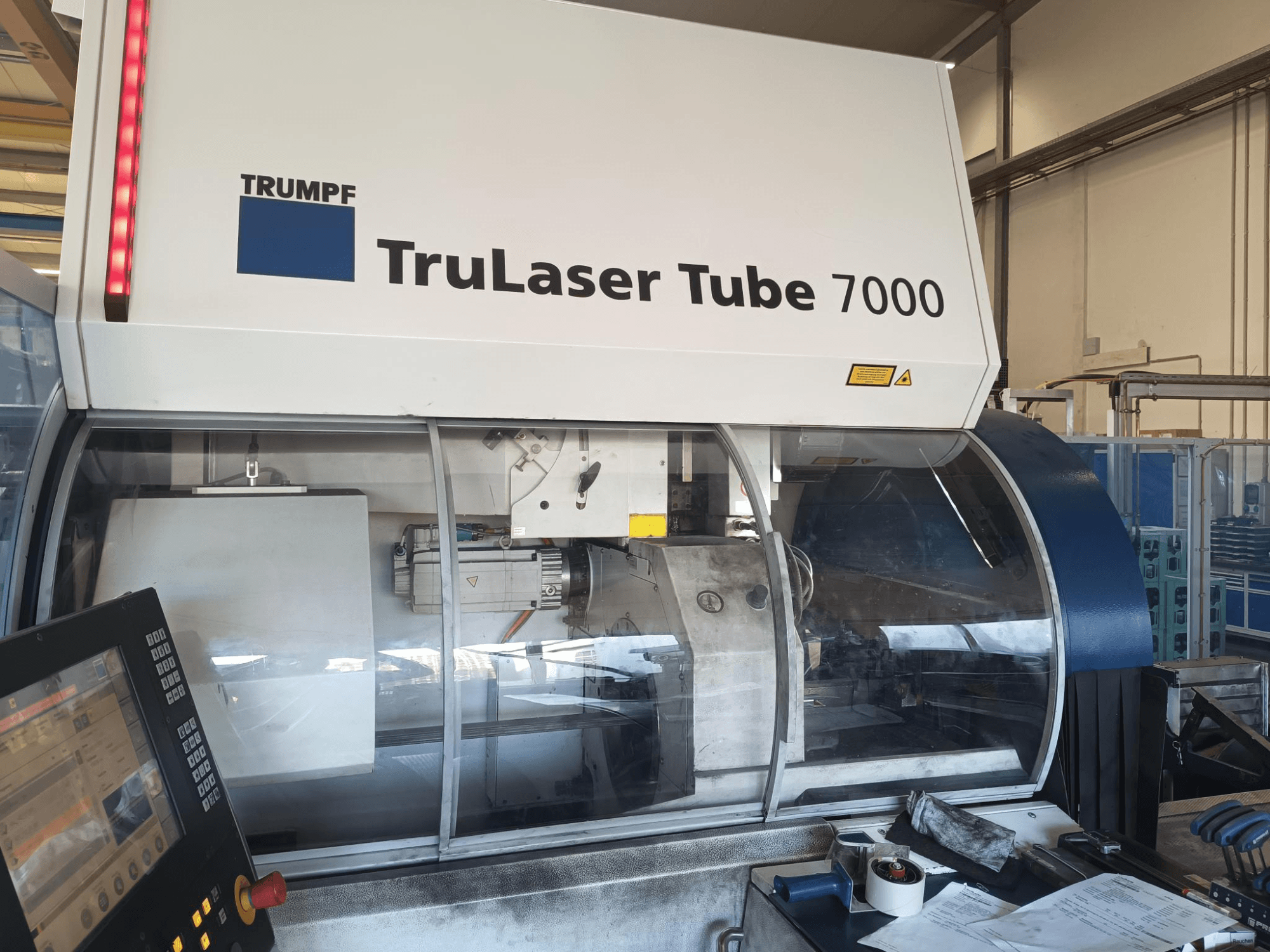

TRUMPF - TruLaser Tube 7000 KT02DE-CUT-TRU-2010-00003

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Sheet Metal Machinery

- ➤ Used TRUMPF TruLaser Tube 7000 KT02 | Tube Cutter

This TRUMPF TruLaser Tube 7000 KT02 was manufactured in 2010. It features a working area of 6500 mm on the X-axis and can handle circular diameters up to 200 mm. Equipped with a CO₂ laser TruFlow 2000 and a laser cutting head with a 155 mm lens, it's ideal for precise tube cutting. Contact us for more information about this machine.

Overview

- brand: TRUMPF

- year: 2010

- MODEL: TruLaser Tube 7000 KT02

- application type: Cutting

- Location: Germany

- machine type: Tube Cutting Machine

- Available from: 01/08/2026

Technical Information - TRUMPF TruLaser Tube 7000 KT02

Movement

- X-axis Travel: 6500 mm

Additional Information

Circular diameter: 200 mm

Reject station: 3 m with brush table

Reject tray

Process/software features: NoLine, PowerLine, ContourLine, Laser power control, Programmable cutting pressure, Program repeat, Automatic blow-off, Work interruption lighting, Hole-punching function (laser)

Laser: CO₂ laser TruFlow 2000

Laser cooling unit

Cutting head: Laser cutting head with 155 mm lens

Control unit: 84D

Connectivity/data transfer: RJ-45 network connection, USB connection; network connection incl. installation

Safety: CE marking, Multi-beam light barriers, Capacitor power 1600 N/cm², Safety with macro stops

Additional equipment

Accessories:

Spare parts case for cutting heads

1 x remote control kit

Clamping jaw set Ø 216 / 200 mm

U-shaped guide rails for reject station with ID = 200 mm

Automation:

LoadMaster Tube 6 m with belt support, 2 grippers

Options for LoadMaster Tube 6 m:

Circular diameter 250 mm

Shorter belt support

Swivelable conveyor section

Additional gripper Ø 200 mm

Additional gripper Ø 250 mm

Special equipment:

Flexible reject station 4.5 m (prototype) instead of reject station 3 m, without brush table

Special installation for flexible reject station

LoadMaster (series version 103)

Installation 100 mm higher (use of wire mesh container possible), decision upon acceptance

Services:

Installation, commissioning, training

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing