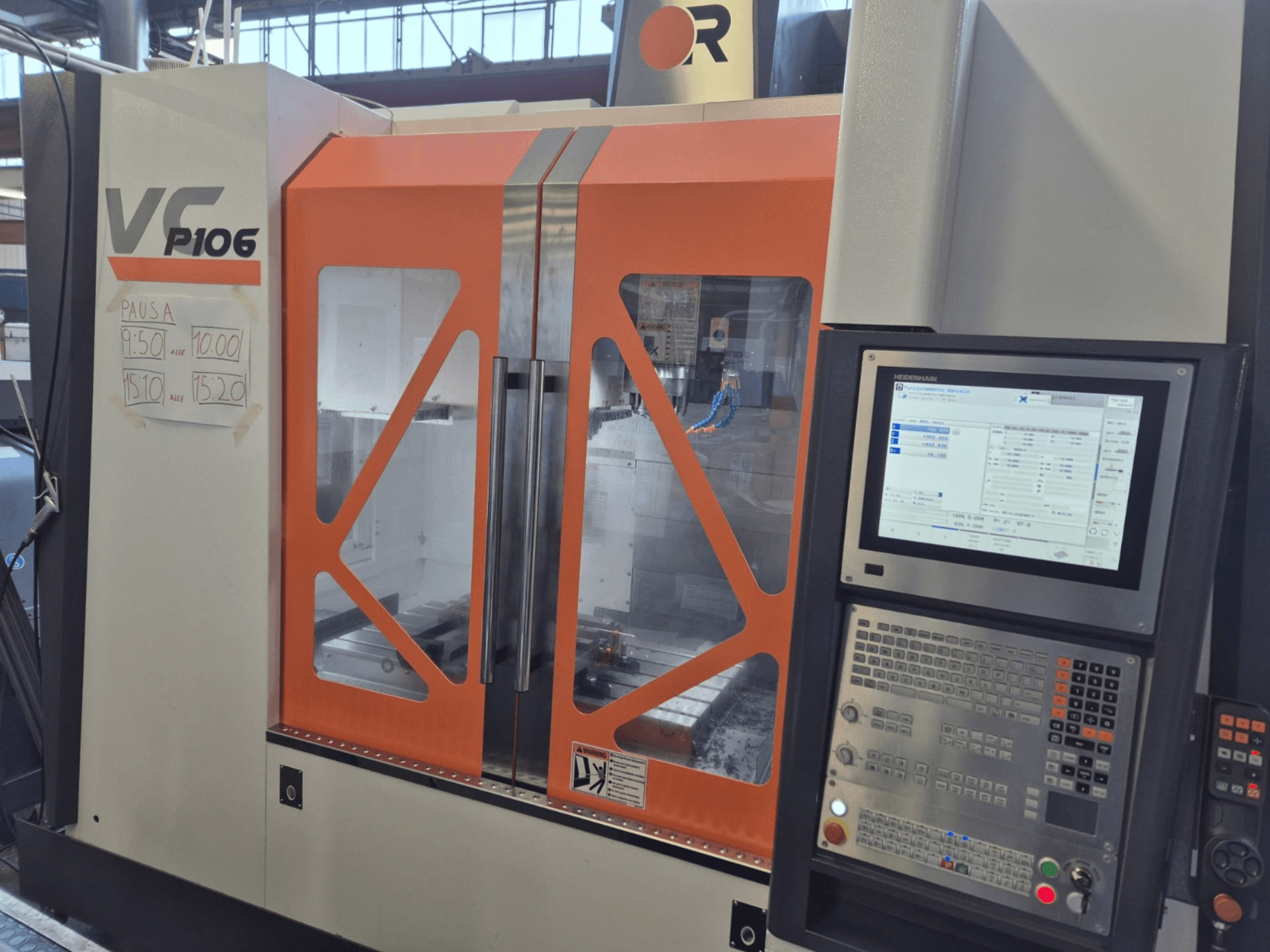

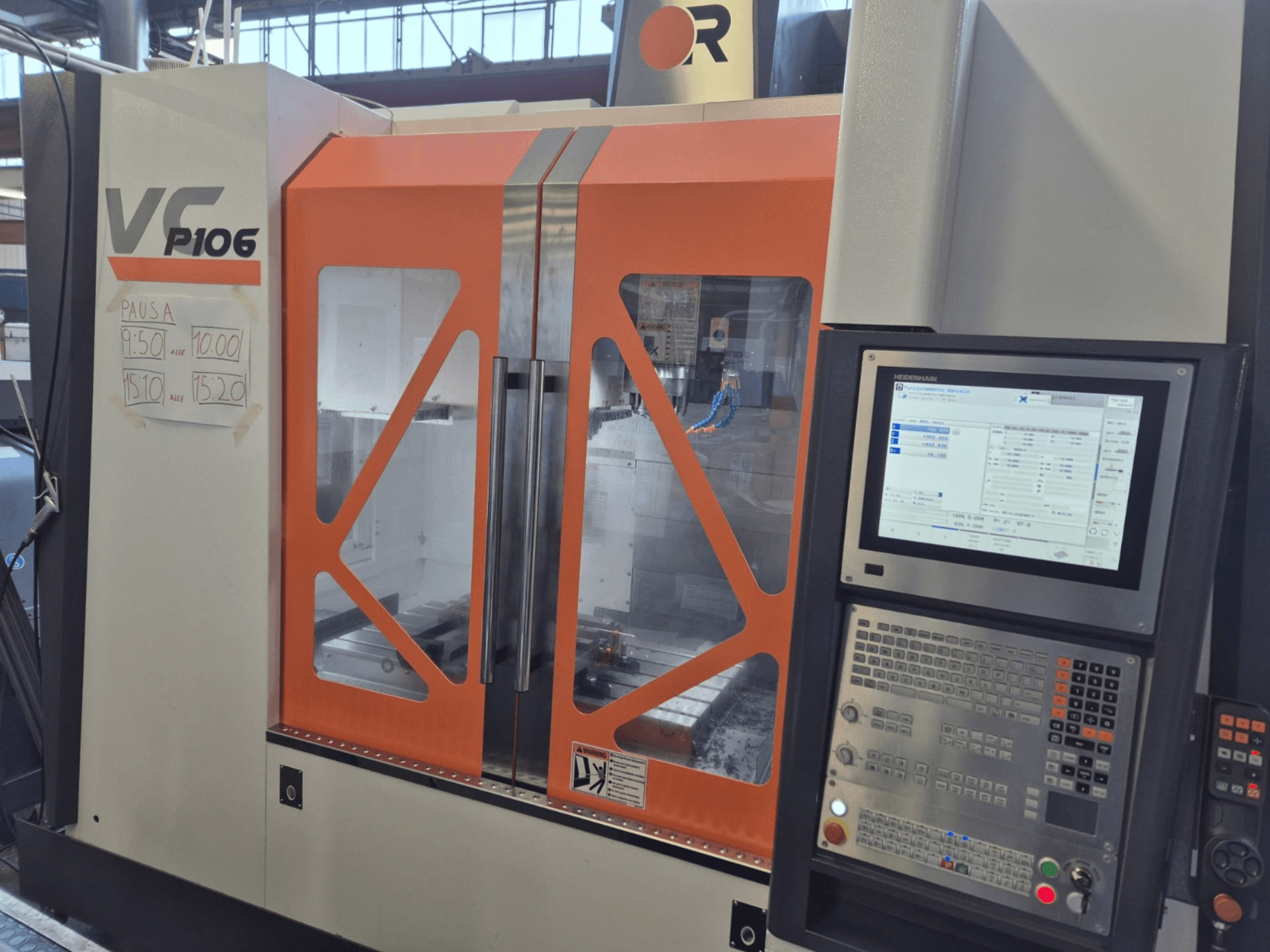

Victor - Vcenter P106IT-MIL-VIC-2023-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used Victor Vcenter P106 For Sale | gindumac.com

This 3-axis Victor Vcenter P106 was manufactured in 2023. It features a Heidenhain 620 CNC, a spindle speed of up to 12,000 rpm, and a tool changer with a 30-tool capacity. The machine offers a robust one-piece Meehanite cast iron base and column, optimized for stiffness and vibration damping. If you are looking to get high-quality milling capabilities, consider the Victor Vcenter P106 machine we have for sale. Contact us for more information.

Overview

- brand: Victor

- year: 2023

- MODEL: Vcenter P106

- application type: Milling

- Location: Italy

- machine type: Vertical Machining Centre

Technical Information - Victor Vcenter P106

Dimensions

- Machine Depth: 3363 mm

- Machine Height: 2812 mm

- Machine Weight: 6850 kg

Additional Information

Additional information

Travels: X-axis 1060 mm, Y-axis 600 mm, Z-axis 560 mm

Rapid feed X/Y/Z: 32 / 48 m/min

Axis servomotor power: 3 kW

Ball screw diameter: 40–45 mm

Ball screw pitch: 16 mm

Guideway width: 45–35 mm

Axis acceleration: 0.5–0.7 G

Table

Size: 520 × 1120 mm

Max load: 600 kg

T-slots: 5 × 18 × 100 mm

Max speed: 12000 rpm

Spindle taper: BBT-40

Motor power: 11–15 kW

Tool Changer Capacity: 30 tools

Max tool diameter (adjacent empty): 75 (150) mm

Max tool length: 300 mm

Max tool weight: 7 kg

Tool-to-tool change time: 2.3 s.

One-piece Meehanite cast iron base and column with oversized ribs for high rigidity

Stabilized outdoors for at least 6 months to remove internal stresses

Designed for efficient chip evacuation and easy operator access

Structure developed with FEA (Finite Element Analysis) for optimal stiffness and vibration damping

Linear guideways on base (X/Y axes) and column (Z axis)

Dual screw conveyors for chip removal

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing

Products related to Victor Vcenter P106

VMX 60

Hurco - Vertical Machining Centre

CMX 70U

DMG MORI - Universal Machining Centre

VF 2 SS

HAAS - Vertical Machining Centre

EC-400

HAAS - Horizontal Machining Centre

ACE HP 4000

DAEWOO - Vertical Machining Centre

V85

MTcut - Vertical Machining Centre

MCPH150 UNIPRO 90

HELLER - Horizontal Machining Centre

DMC-63V

DECKEL - Vertical Machining Centre

DMC 60T

DMG DECKEL MAHO - Universal Machining Centre

C 800 V

HERMLE - Vertical Machining Centre

VCN 700E/40-II

Mazak - Vertical Machining Centre

VMX24t

Hurco - Vertical Machining Centre