Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

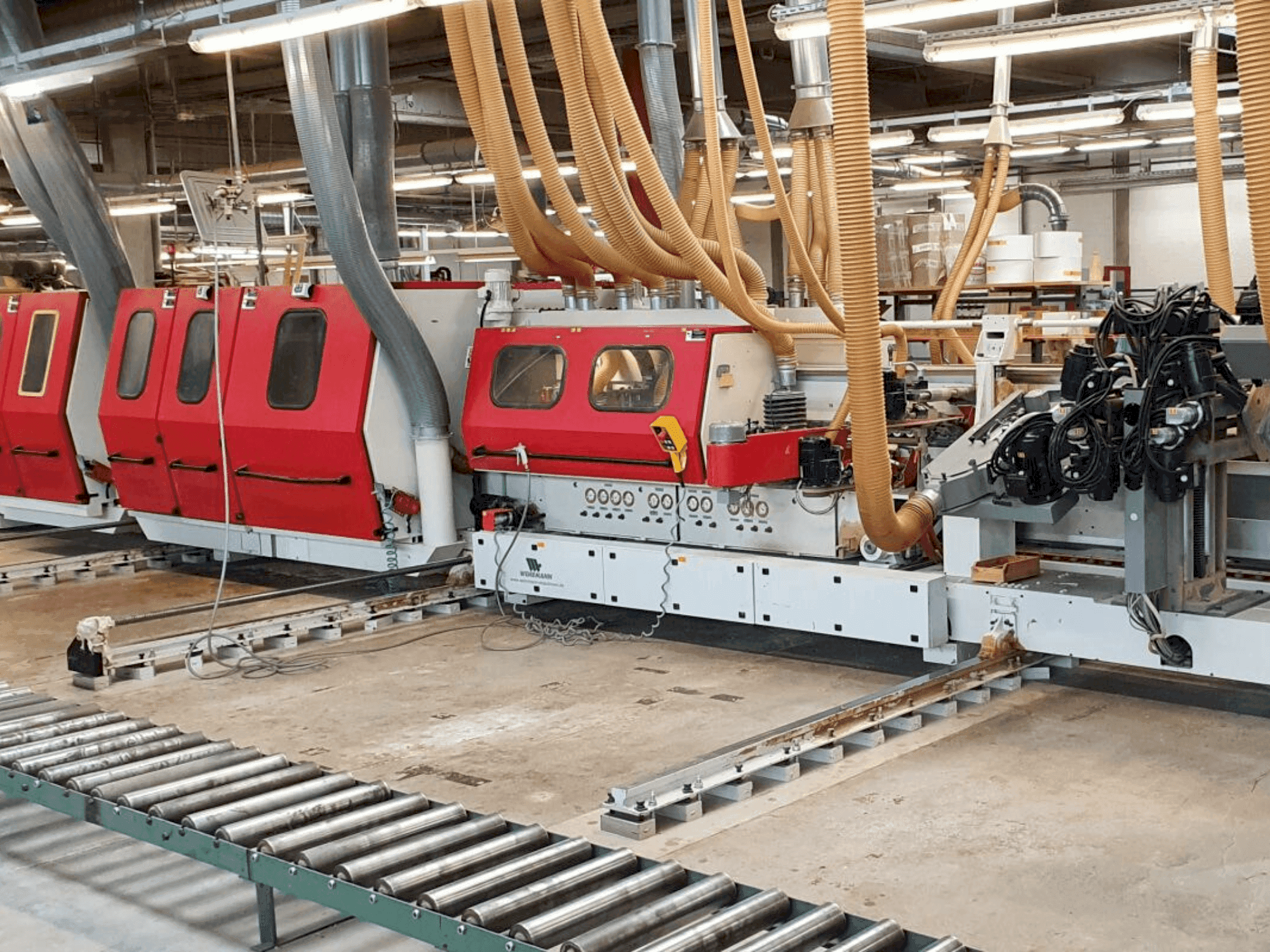

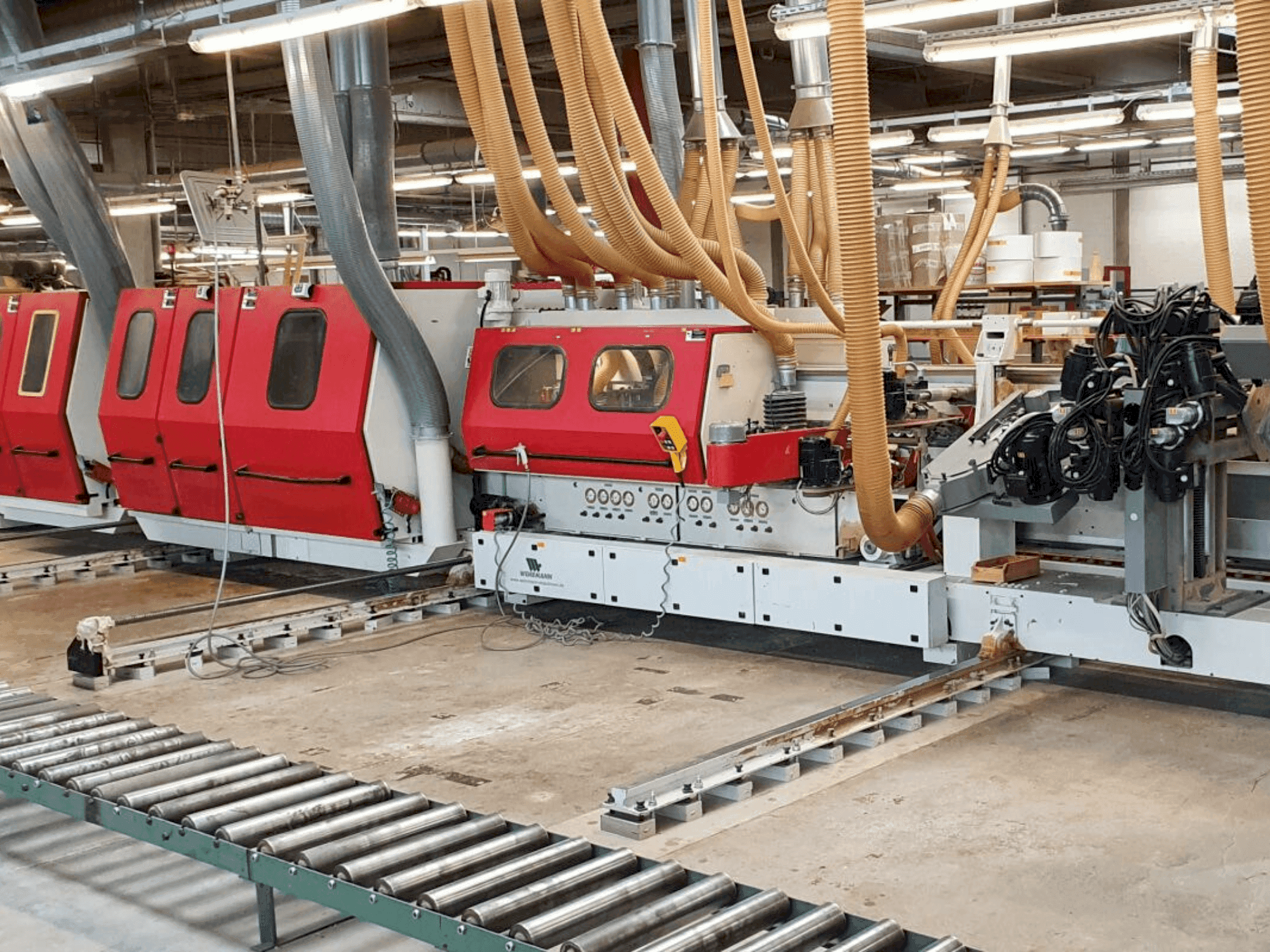

WEHRMANN - CombimaDE-WOO-WEH-2007-00002

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Wood Working

- ➤ Used WEHRMANN Combima - 2007 - Double end tenoner

This Wehrmann Combima was manufactured in 2007. A robust double end tenoner for solid wood panels featuring a maximum working width of 2,500 mm and a minimum of 280 mm. Equipped with a Beckhoff machine control, fast Pentium computer, and touchscreen display. It includes a milling unit with a 6.6 kW motor and a double hogger unit for efficient processing. A great opportunity to buy this Wehrmann Combima woodworking machine. For more information about this woodworking machine, please reach out to us.

Overview

- brand: WEHRMANN

- year: 2007

- MODEL: Combima

- application type: Edge Banding

- Location: Germany

- machine type: Edgebander

- control unit brand: BECKHOFF

Technical Information - WEHRMANN Combima

Control Unit

- Control Brand: BECKHOFF

Additional Information

Additional equipment

- Milling units: Two controllable, non-pivotable milling units with motors of 6.6 kW each, capable of vertical and horizontal adjustments via electric axis.

- Double hogger unit: Upper and lower hogger motors each 4.4 kW, with horizontal and vertical adjustment.

- Profile/milling units: Three controllable, pivotable units with motors of 4.4 kW each, capable of comprehensive adjustments including swivel.

- Radius milling units: Three units with upper and lower motors of 660 W each, approximately 25 degrees pivotable.

- Edge sanding unit: For grinding vertical workpiece edges, oscillating, with a maximum workpiece height of approximately 80 mm.

- Profile sanding units: Multiple units for grinding small profiles, with motors of 0.55 kW and 1.1/1.8 kW.

- Suction sluice with blow nozzle.

- Extension device approximately 700 mm long.

Machine Benefits

Qualitative Machine Benefits

- High-quality construction and robust design ensure durability and consistent performance.

- Advanced sanding technology from heesemann ensures superior surface finish and detail in profiling.

- Equipped with low-maintenance precision roller transport chains for reliable and smooth operation.

Technical Machine Benefits

- Double end tenoner for massive wood panels

- Versatile processing capabilities with multiple milling, sanding, and profiling units, allowing for comprehensive treatment of wood panels.

- Nc controlled for precise adjustments and operations, enhancing the quality and efficiency of production.

- Modular equipment setup provides flexibility in configuring the machine for specific production requirements.

- Working width: maximum of approximately 2,500 mm and minimum of approximately 280 mm.

- Machine control via a fast pentium computer with a touchscreen display and integrated programming software, providing a user-friendly interface and efficient management of operations.

Extra Information

Machine control via a fast Pentium computer with a touchscreen display and integrated programming software, providing a user-friendly interface and efficient management of operations.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing