Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

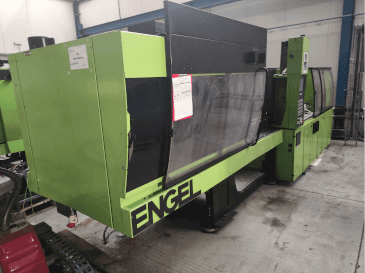

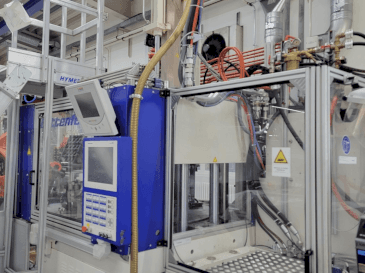

Engel - Victory 750 / 220 spexDE-INJ-ENG-2015-00005

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Plastics Processing Machinery

- ➤ Used Engel Victory 750 / 220 spex | Injection Moulding

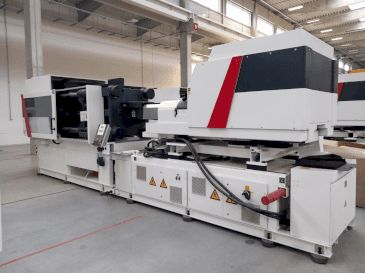

This Engel Victory 750 / 220 spex was manufactured in 2017. It features a hydraulic movable clamping plate, advanced material package for processing thermoplastics, and a bi-metal cylinder resistant to abrasion and corrosion. The machine includes a CC300 microcomputer with a 21.5-inch full HD touchscreen for intuitive control and a user authorization system. Ideal for detailed thermoplastic processing. Contact us for more information about this machine.

Overview

- brand: Engel

- year: 2017

- MODEL: Victory 750 / 220 spex

- production hours: 5900

- application type: Injection Moulding

- Location: Germany

- machine type: Hydraulic Injection Moulding Machine

Technical Information - Engel Victory 750 / 220 spex

Additional Information

Control Unit CC300 Microcomputer: Visualization on a 21.5" full HD touchscreen color monitor with high sensitivity

Ergonomic screen positioning with automatic adjustment

User authorization system according to Euromap 65 including 3 keycards

Intuitive and fast navigation with a component- and task-oriented operating concept

One-touch operation and sensitive motion control with the central e-move control element

Individual assignment of functions to the freely configurable hand keys

Cycle sequence freely programmable via graphic symbols

Optical fault signal display on the control panel

Setting data storage via USB interface

Ethernet network interface

Freely configurable screen pages

Weekly timer

Process data log

Continuous graphical monitoring of process parameters with PD-Graphic I

Micrograph and Microplast available

Injection molding machine energy consumption analysis with Ecograph

Injection Unit Material Package: For processing thermoplastics with a maximum reinforcement of 30%, corrosion-resistant, usable up to 350°C

Melt Cylinder: M3 Standard Melt Cylinder Bi-metal (Fe-Bass), abrasion- and corrosion-resistant, usable up to 350°C

Non-Return Valve: Standard Rub with ring for backflow prevention, abrasion- and corrosion-resistant

Screw: Diameter 45 mm L/D 20, fully hardened, abrasion and corrosion-resistant

Nozzle: Open, corrosion-resistant, Flange thread M45x3, Nozzle radius 35 mm, Nozzle bore 4 mm

Clamping Force Double Core Puller: Hydraulic movable clamping plate with shut-off valve and pressure relief

End Position Monitoring Interface: According to Euromap 13 / AN-147 2-Speed Hydraulic Movable

Clamping Plate: With shut-off valve and pressure relief

Media Supply Voltage: 3x400V+N+PE/50 Hz

Cooling: Separated cooling water connection for machines and/or work cooling

Interface for Temperature Control Units: Includes locking side and data protocol Engel, 20mA-CL Temperature

Control Hoses: 1/2" (max. 90°C, 4 bar) with color coding on hose ends: red/blue

Control Circuits: 3 circuits at the rear of the machine with connection plate (R3/8" thread)

Extra Information Mounted Devices: Mass hopper mounted on sliding unit with step-up aid for manual filling according to EN ISO 14122 1-4

Electrical Chain: For potential-free system

Ejector Safety Interface: Solenoid valve 2/2-way, R1/4 inch, mounted on FAP, only for blowing function

Extension Package EP2: Includes interface for potentiometer contacts, and 4x digital output/input

Additional equipment

Polycarbonate Viewing Window

Injection Unit with Protective Guard and Sliding Guard

Advanced Material Package

Moretto Granular Dryer included

Moretto Kältemaschine included T

ool Temp Temperature control unit included

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing

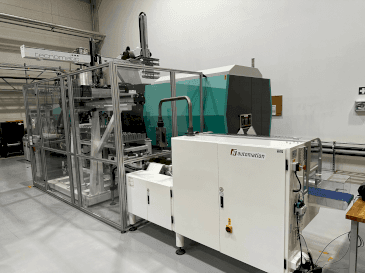

Products related to Engel Victory 750 / 220 spex

CJ480M3V

CHENDE - Hydraulic Injection Moulding Machine

130-380 CX

Krauss Maffei - Hydraulic Injection Moulding Machine

Systec 160-520/430

DEMAG - Hydraulic Injection Moulding Machine

SYNERGY 1500-600

Netstal - Hydraulic Injection Moulding Machine

Elektron Evo 350

Milacron - Electrical Injection Moulding Machine

Allrounder 920H 5000-4600

Arburg - Hydraulic Injection Moulding Machine

MA900 II eco

HAITIAN - Hydraulic Injection Moulding Machine

Victory 750/200 Tech

Engel - Hydraulic Injection Moulding Machine

S 6000-5500E

Netstal - Hydraulic Injection Moulding Machine

ALLROUNDER 1200 t 1000 - 400

Arburg - Hydraulic Injection Moulding Machine

Allrounder 520S-1600-400

Arburg - Hydraulic Injection Moulding Machine

VM 150/750V R1520 UNIGLOG B6S

Battenfeld - Hydraulic Injection Moulding Machine