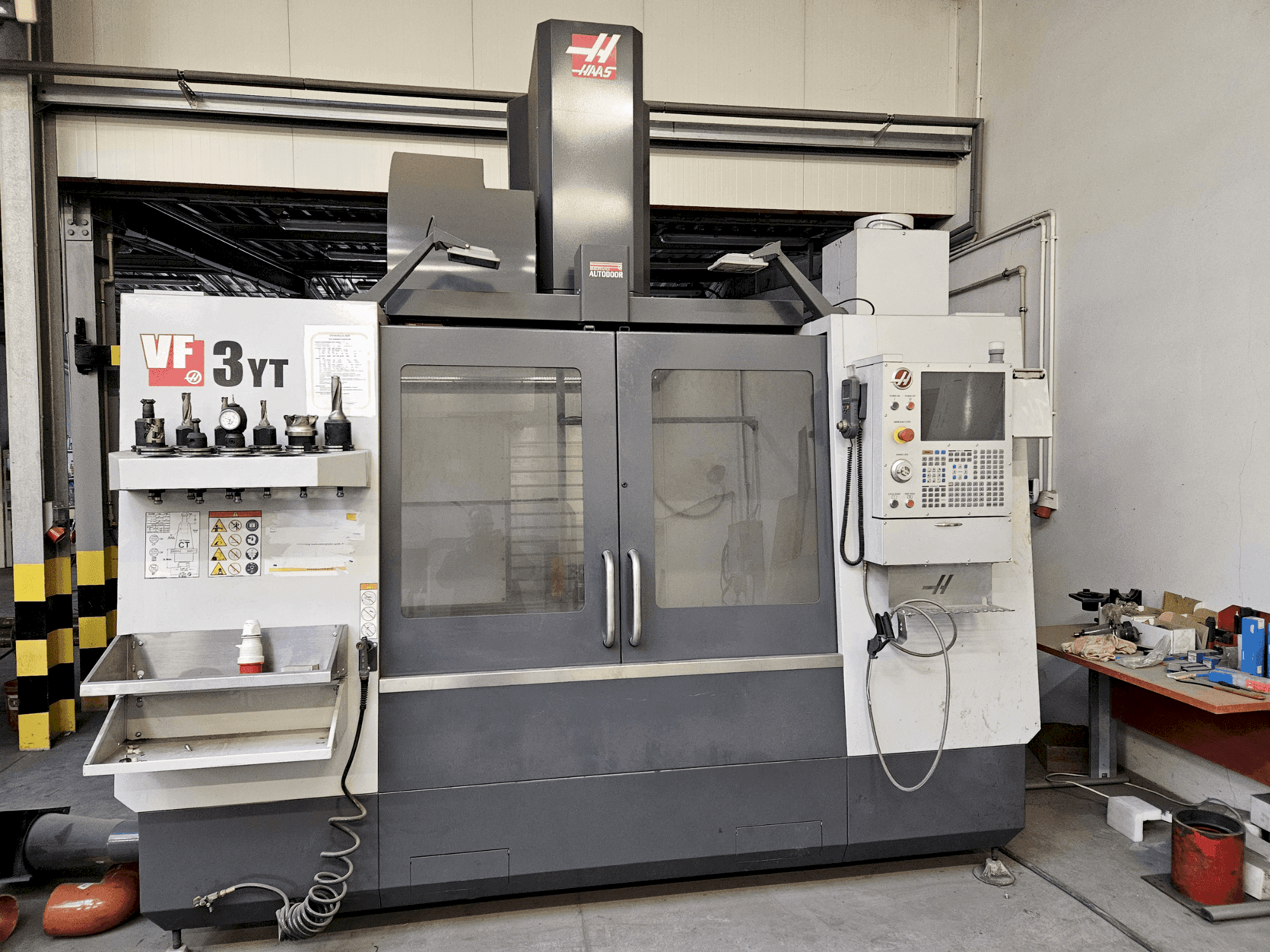

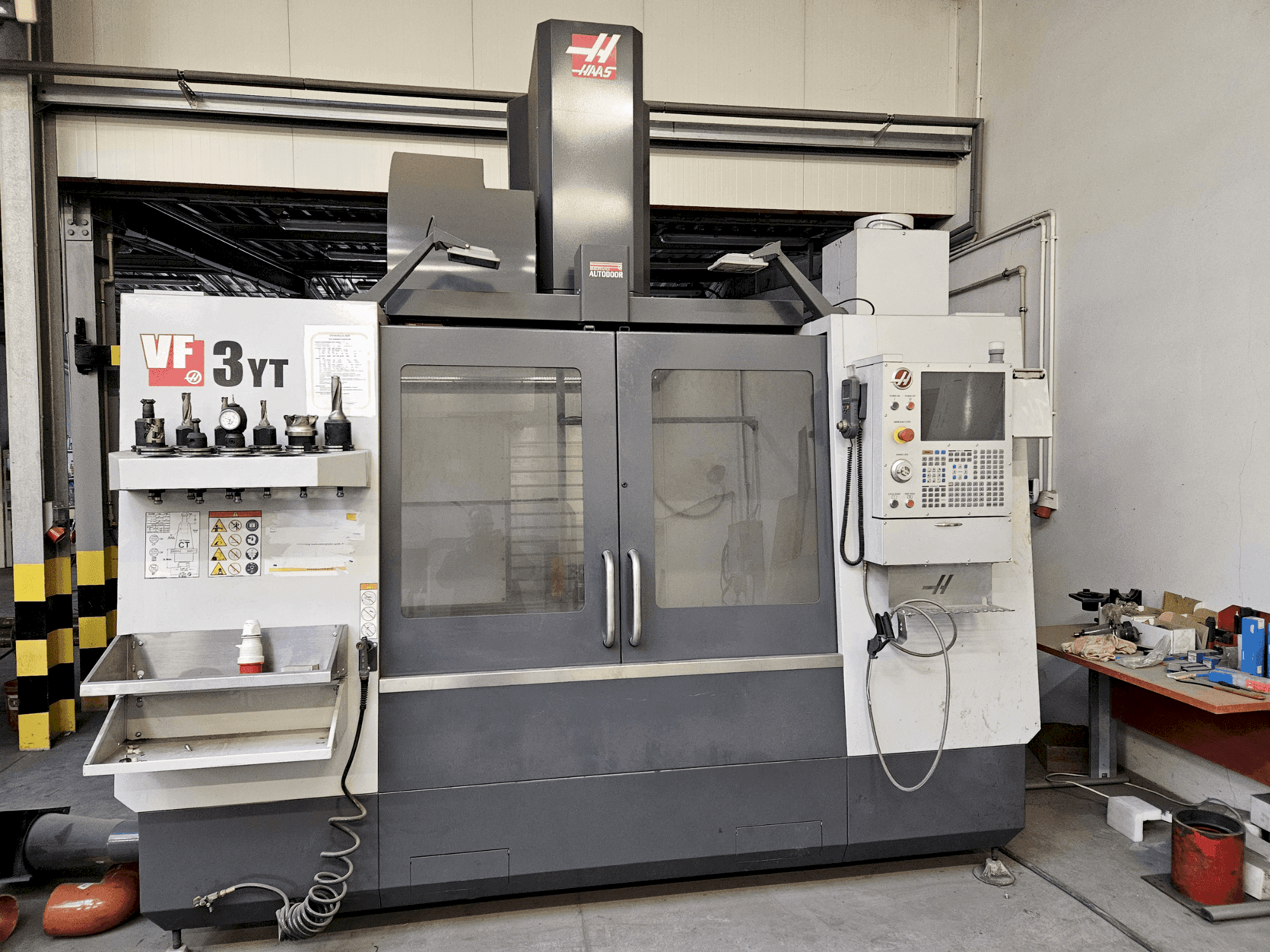

HAAS - VF-3YT/50PL-MIL-HAA-2017-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- HAAS VF-3YT/50 Vertical Machining centre

This HAAS VF-3YT/50 Vertical Machining centre was manufactured in the year 2017 in the United States and has 238 production hours. It is equipped with a HAAS control unit and has 3 axis. The machine has a spindle speed of 12000 rpm.

Overview

- brand: HAAS

- year: 2017

- MODEL: VF-3YT/50

- production hours: 238

- application type: Milling

- Location: Poland

- machine type: Vertical Machining Centre

- control unit brand: HAAS

Technical Information - HAAS VF-3YT/50

Control Unit

- Control Brand: HAAS

Dimensions

- Machine Weight: 7212 kg

- Table Length: 1372 mm

- Table Width: 610 mm

Movement

- Number of Axes: 3

- X-axis Travel: 1016 mm

- Y-axis Travel: 660 mm

- Z-axis Travel: 635 mm

Technical Specification

- Number of Tools: 30

- Spindle Speed: 7500 RPM

Additional Information

Machine Benefits

Qualitative Machine Benefits

- Screw chip conveyor

- Spindle taper air blow

- Thread cutting without compensation chuck

- Installation for compressed air connection

- Early power failure detection module

- Programmable coolant nozzle angle position

- Remote control pendant with lcd display /jog handle/

- Cooling system with pull-out coolant tank

- Automatic central lubrication system

- Wips-r wireless probing system for measuring tools in radius and length, for measuring and setting parts with measuring cycles. Includes so, macro, coord, and vps (visual programming system)

Technical Machine Benefits

- Cooling trough the spindle

- Spindle taper iso50, ct type

- Memory capacity 1 gb, network card

- Haasconnect – remote monitoring of machine working condition

- 15” lcd monitor and usb port

- Electronic handwheel

- Spindle cooling system

- Temperature compensation for lead screws

- Protective cabin with sliding front doors and side windows that can be tilted open

- 30-position magazine

Extra Information

-CT Spindle taper, CT type -ACF Additional 25 μm filtering system, essential for machining cast iron, aluminum, wood, phenolic resin-based plastics, and other dust-generating materials -TSC* Through-spindle cooling, high-pressure pump /21 bar, 22 l/min/ (ACF option required) -HIL Additional halogen chamber lighting -ENCL EXHAUST Oil mist extraction system. Can be connected to a ventilation network -WIFI Wireless network -TAB Air blast through spindle.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing