Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

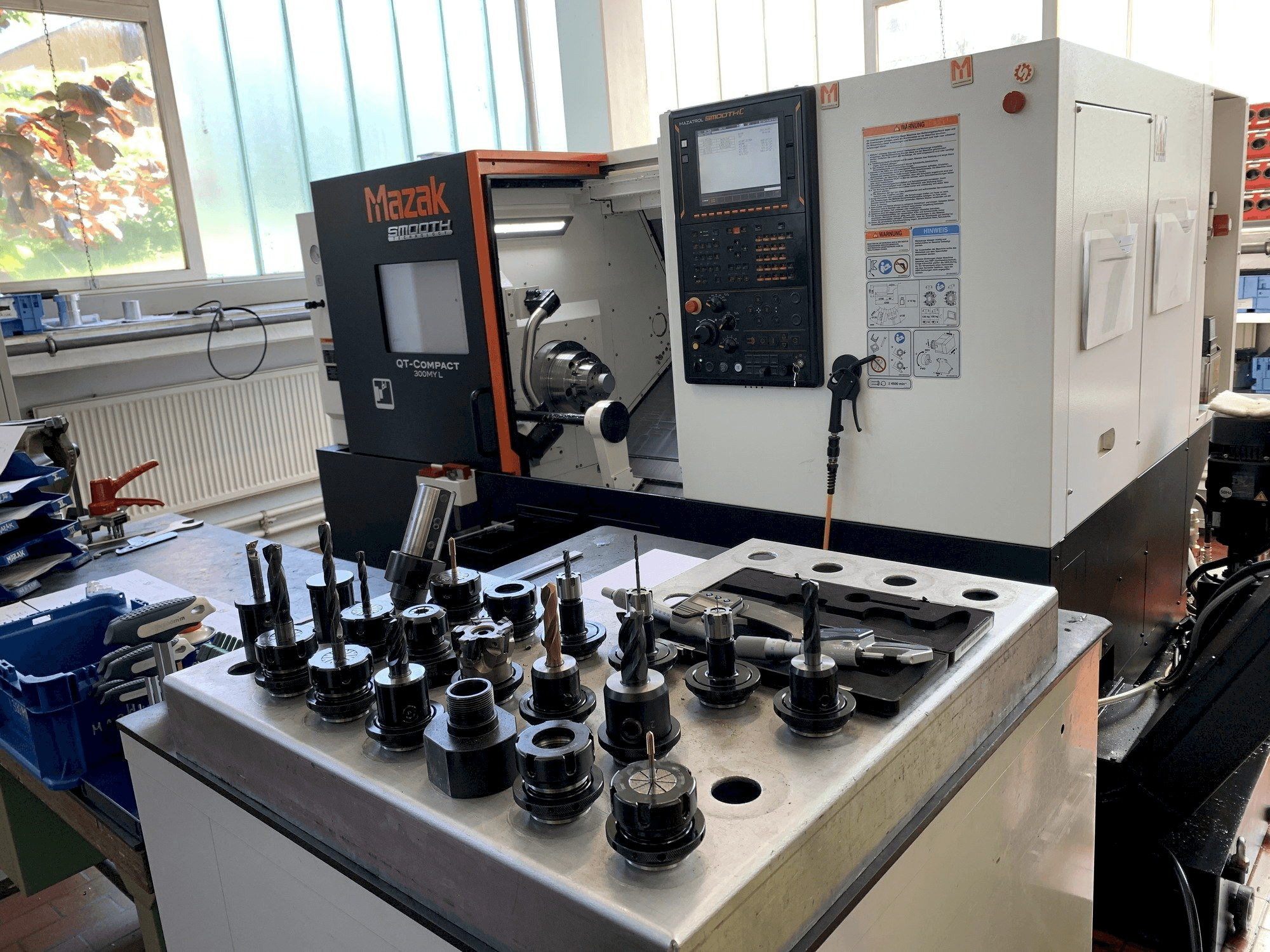

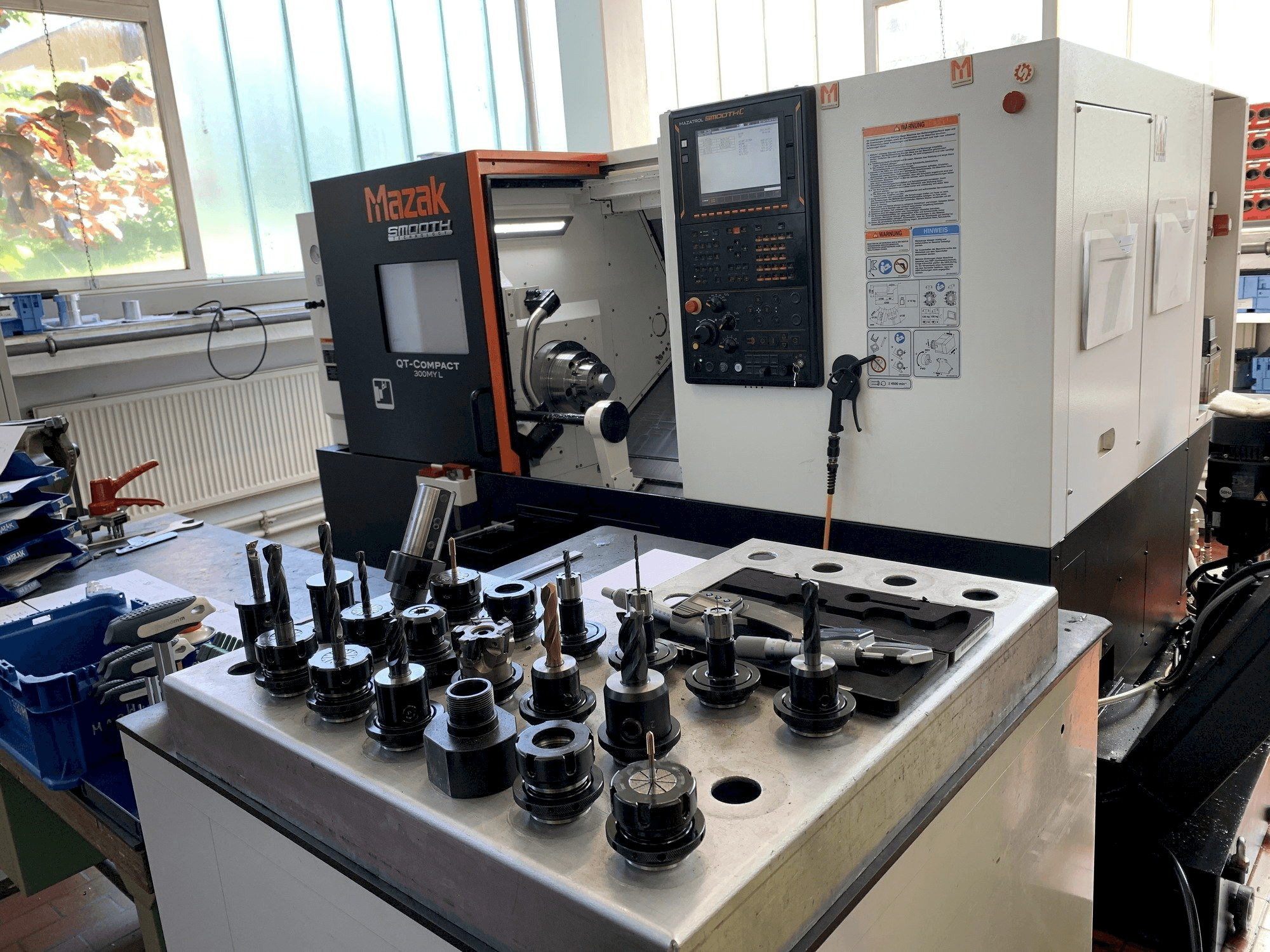

Mazak - QTC 300MY L500DE-TUR-MAZ-2018-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- Mazak QTC 300MY L500

This Mazak QTC 300MY L500 Lathe was made in China in the year 2018. It has been working for 5056 hours. This 3 axis machine is operated through a MAZATROL SMOOTHC control unit. It can work with a spindle speed up to 4000 rpm and a spindle bore 91 mm. This machine includes several options as 1 set of adjustment tools and a small tool box with a spanner, screwdriver and an Allen key. It comes with a set of manuals in electronic form on OD.

Overview

- brand: Mazak

- year: 2018

- MODEL: QTC 300MY L500

- production hours: 5056

- application type: Milling

- Location: Germany

- machine type: Universal Machining Centre

- control unit brand: MAZATROL

Technical Information - Mazak QTC 300MY L500

Control Unit

- Control Brand: MAZATROL

- Control Model: SMOOTHC

Dimensions

- Machine Depth: 2700 mm

- Machine Height: 1725 mm

- Machine Weight: 4670 kg

Movement

- Number of Axes: 3

- X-axis Travel: 215 mm

- Y-axis Travel: 100 mm

- Z-axis Travel: 605 mm

Technical Specification

- Spindle Power: 15 kW

- Spindle Speed: 4000 RPM

Additional Information

Additional equipment

- B688EL110 Transformer for the European market

- B688M0575 Use of linear systems with carriages from leading manufacturers

- B688N0839 SD MEMORY l/F(1P) + USB MEMORY l/F(1P) 1 x USB - Memory Interface (1 SIot)

- B688SD120 1 set of adjustment tools

- Small tool box with - spanner - Screwdriver - l Allen key

- B688SD130 Machine feet / levelling shoes

- B688S1039 C-axis input accuracy 0.0001

- B688TT014 Integrated travelling quill MK 4 (1000)

- B688TT640 Tailstock with fixed quill MK5 (500U)

- B688YI 030 Y-axis control

Machine Benefits

Qualitative Machine Benefits

- Tool cross-section (external turning tool) 565 mm2

- Boring bar diameter (max. ) 40 mm

- Tool size drill 20 mm

- Tool size milling cutter 20 mm

- Switching time 1 turret station 0. 23 s

- Switching time full turret rotation 0. 63 s

- Milling spindle power (continuous operation) 3. 7 kw

- Milling spindle power (40% ed) 5. 5 kw

- Max. Milling spindle speed milling spindle speed 4500 min-1

- Max. Milling spindle torque 47. 0

Technical Machine Benefits

- Chuck diameter main spindle 10''

- Max. Swing diameter 695 mm

- Standard machining diameter 255 mm

- Max. Machining diameter 340 mm

- Max. Bar diameter main spindle 80 mm

- Distance between spindle end and turret 59. 5 - 664. 5 mm

- Max. Workpiece weight chuck machining main spindle 450 kg

- Spindle nose a2-8

- Max. Torque 356. 0 nm

- Travel range tailstock body 565 mm

Extra Information

Set of manuals in electronic form on OD

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing

Products related to Mazak QTC 300MY L500

VMX 60

Hurco - Vertical Machining Centre

CMX 70U

DMG MORI - Universal Machining Centre

VF 2 SS

HAAS - Vertical Machining Centre

EC-400

HAAS - Horizontal Machining Centre

ACE HP 4000

DAEWOO - Vertical Machining Centre

INTEGREX 200 IV S

Mazak - Turn-Mill Centre

V85

MTcut - Vertical Machining Centre

MCPH150 UNIPRO 90

HELLER - Horizontal Machining Centre

DMC-63V

DECKEL - Vertical Machining Centre

DMC 60T

DMG DECKEL MAHO - Universal Machining Centre

QTN 250M 1000L

Mazak - Horizontal Turning Machine

PICOMAX 55 CNC 2/3

FEHLMANN - Vertical Machining Centre