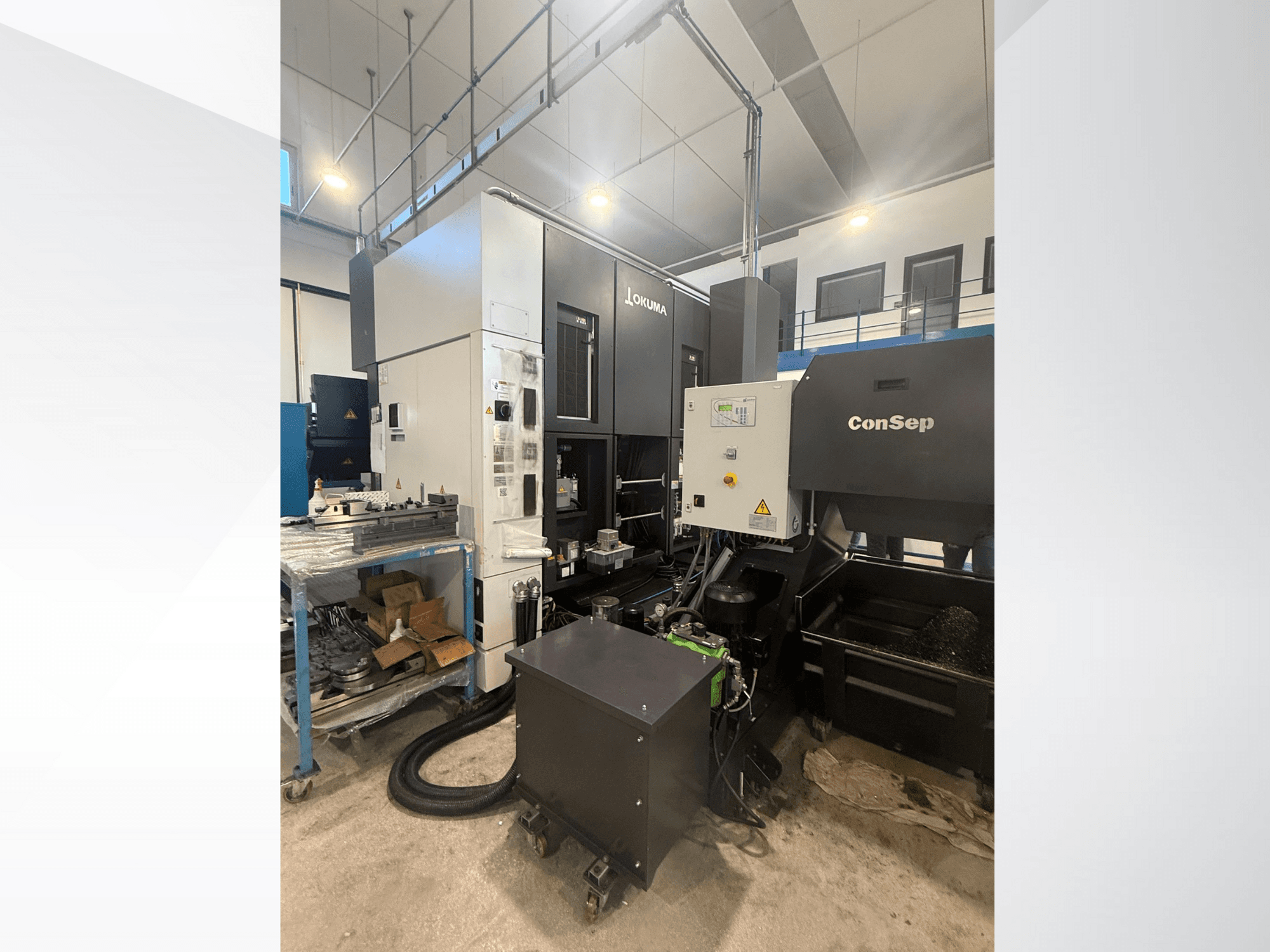

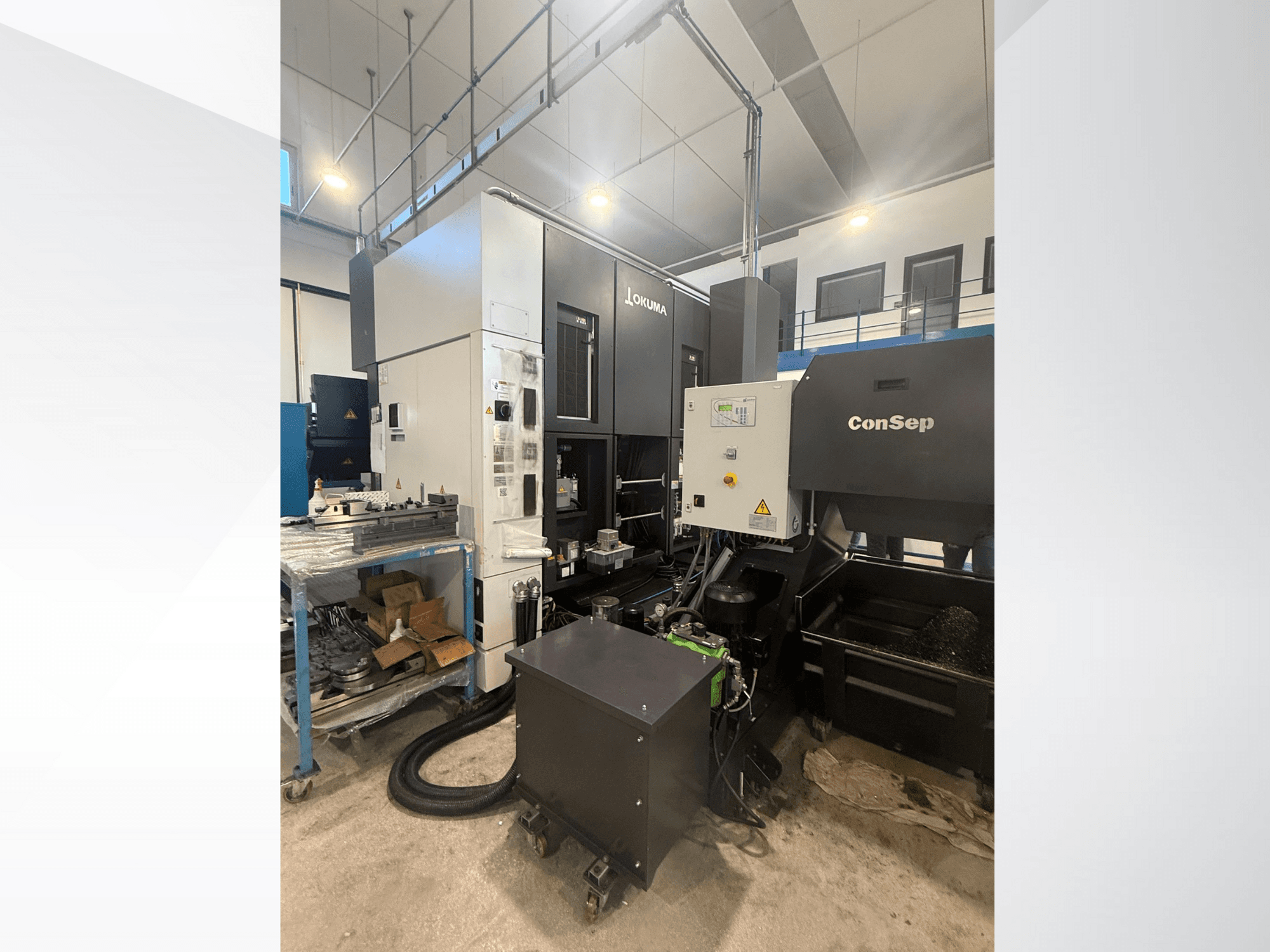

Okuma - MU-6300V-LIT-MIL-OKU-2022-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used Okuma MU-6300V-L For Sale | gindumac.com

This 5-axis Okuma MU-6300V-L was manufactured in 2022. It features a vertical machining center with turning function, equipped with a multifunction spindle capable of 12,000 rpm and a turning spindle speed of 800 rpm. The machine includes a high-pressure coolant system at 70 bar, a 64-tool automatic changer, and advanced collision avoidance. It supports 5-axis simultaneous machining, enhancing precision and efficiency. Contact us for more information about this machine.

Overview

- brand: Okuma

- year: 2022

- MODEL: MU-6300V-L

- application type: Milling

- Location: Italy

- machine type: Vertical Machining Centre

Technical Information - Okuma MU-6300V-L

General Data

- Machine weight: 13000 kg

Main drive

- Spindle speed range: 8000 rpm 1/MIN

- Spindle motor power: 11 / 7.5 kW

Movement

- X-AXIS Movement: 925 MM

- Y-AXIS Movement: 1050 MM

- Z-AXIS Movement: 600 MM

Additional Information

Additional information

Rapid feed X/Y/Z: 50 m/min

Rotary axes: A +90° / -120°, C 360°

Table diameter: Ø630 mm

Table load: 600 kg

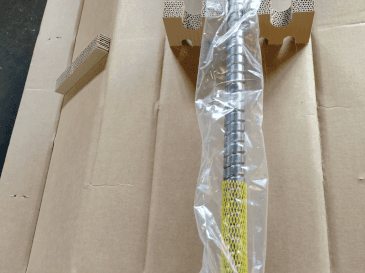

Tool taper: HSK-A63

Tool magazine: 64 tools (ATC chain type)

Thermal compensation on all axes (X/Y/Z)

Cooling ball screws on X/Y/Z axes

Automatic tool changer

High-pressure coolant system 70 bar

Chip conveyors

Automatic safety door with interlock

Work area status lamp

Palletizing system predisposition

Robot interface DeviceNet/ProfiNet

External M-code command, 8 points

USB ports and Ethernet DNC-B

Interactive gauging function

Additional 400 work coordinate offsets

CAS (Collision Avoidance System)

API Library 2 (ON Status)

Virus Protection System

Vibration Suppression Software "Navi M-i"

Excel Machining

External program selection

DNC-DT transmission interface

Programmable and operation messages

5-Axis Simultaneous Machining Kit

Hyper Surface

Vector and manual vector control

High-Spec Geometric Requalification Kit

Geometric error measurement and compensation

Renishaw RMP60 probe system

Optical scales on X-Y-Z axes

Magnetic-base calibration sphere

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing

Products related to Okuma MU-6300V-L

VMX 60

Hurco - Vertical Machining Centre

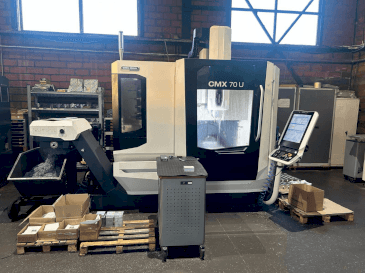

CMX 70U

DMG MORI - Universal Machining Centre

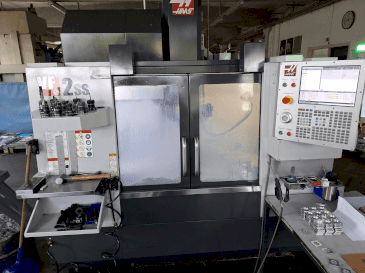

VF 2 SS

HAAS - Vertical Machining Centre

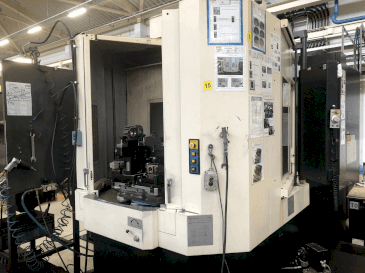

EC-400

HAAS - Horizontal Machining Centre

HM 6300

DOOSAN - Horizontal Machining Centre

A61-5XR

Makino - Horizontal Machining Centre

ACE HP 4000

DAEWOO - Vertical Machining Centre

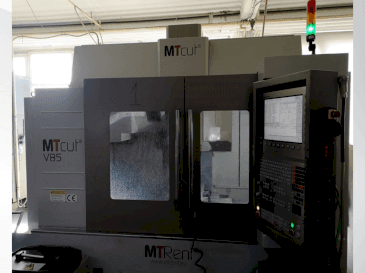

V85

MTcut - Vertical Machining Centre

MCPH150 UNIPRO 90

HELLER - Horizontal Machining Centre

DMC-63V

DECKEL - Vertical Machining Centre

VTC-300C

Mazak - Vertical Machining Centre

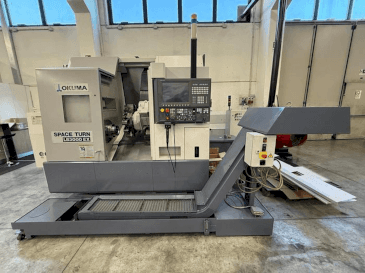

LB 3000 EX MYT

Okuma - Horizontal Turning Machine