Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

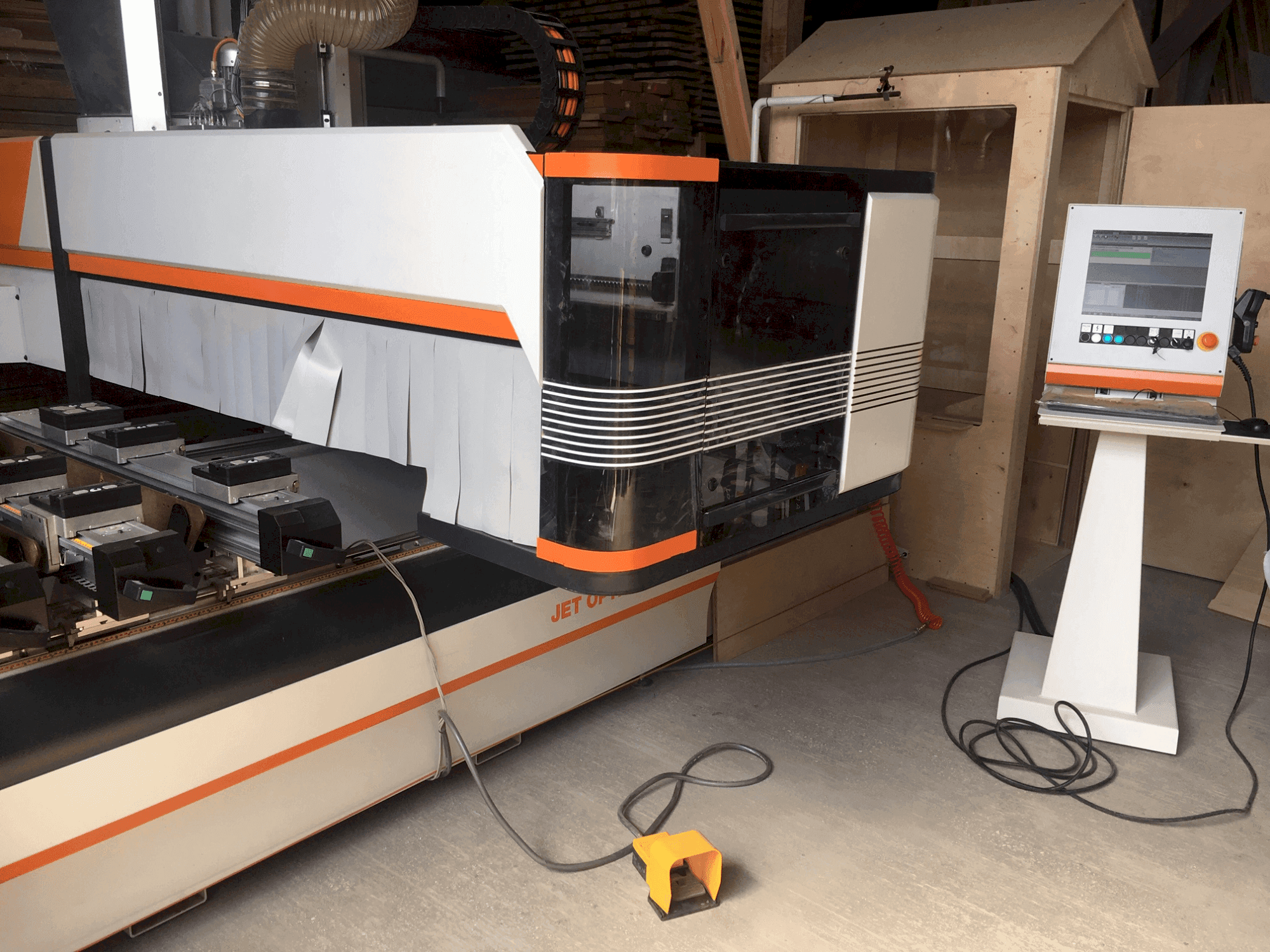

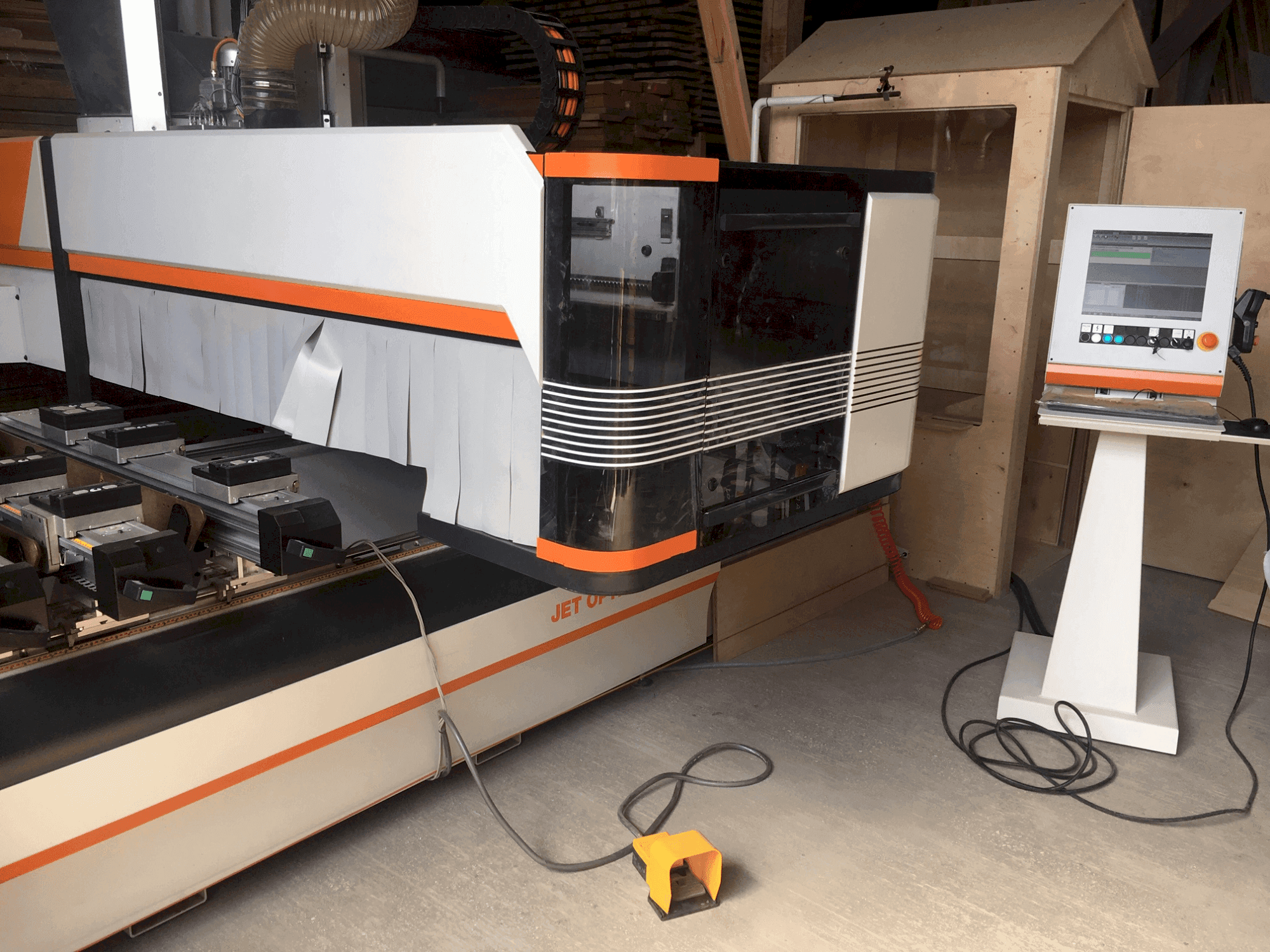

BUSELLATO - Jet Optima T5HU-WOO-BUS-2018-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Wood Working

- Busellato Jet Optima T5 Wood working machine

This Busellato Jet Optima T5 Wood working machine was manufactured in the year 2018. It is equipped with a TPA control unit and has 5 axis.

Overview

- brand: BUSELLATO

- year: 2018

- MODEL: Jet Optima T5

- application type: CNC Wood Machining

- Location: Hungary

- machine type: CNC Router

Technical Information - BUSELLATO Jet Optima T5

Movement

- Number of Axes: 5

Additional Information

Machine Benefits

Qualitative Machine Benefits

- Automatic tool radius correction, drilling head 18m (8x + 5y), 6 horizontal drills (4x - 2y), circular saw: 120 mm.

- Toolpath optimization between machining operations, 5-axis "jet 5" water-cooled head with hsk 63 tool clamping, b: +185° to -95°, c: +/- 360°, working area: 3050 x 1250 mm.

- Graphic representation of tool library settings, display of spindle speed and aggregate positions.

- 2d simulation and software calculating cycle times, controller and diagnostic synopses for easier machine operation.

- Printing and graphical printing of programmed workpieces with iso codes, genesis evolution machine control software.

- Programs can be easily reviewed using the "preview" function, electro-welded machine frame and moving console with reinforced, ribbed steel alloy plates, especially strengthened at the most loaded points.

- Manual and machine diagnostic functions with real-time repair suggestions and graphical assistance.

- Graphic assistance during machine programming. , repeating program lists and executing custom programs.

- Import of iso text files, "hold" function with safety mat, z-axis movement facilitated by ball screw spindles.

- Editing along curves and arcs for character height, spacing, line spacing, and letter spacing, "sc" electrode spindle 11 kw – speed 20,000 rpm hsk, pc console with windows operating system, 17" lcd monitor.

Technical Machine Benefits

- The machine's axial z-axis working height is 180mm. Actual axis positional speeds are as follows: x-axis: 70 m/min y-axis: 60 m/min z-axis: 30 m/min

- Key features include: integrated cad with reflection, rotation, repetition functions, etc.

- The operating system allows real-time control of the machine, automatic control of working speed with route optimization, automatic centralized lubrication system.

- Display of 2d and 3d representations of workpieces, circular 12-tool hsk 63 tool magazine.

- Parametric programming allowing the use of mathematical, trigonometric, inverse trigonometric, and logical formulas, with 300 variables for executing these formulas.

- Viewing and rotation of horizontal and vertical views, automatic reduction of feed speed based on inverter operation.

- Simple and multifunctional programming in multiple views, linear 10-tool hsk 63 tool magazine.

- Automatic speed control for tool engagement, y-axis movement facilitated by ball screw spindles.

- Tool parameter retrieval from the program, x-axis displacement achieved through a convex curved toothed rack and pinion contact.

- Higher-level programming (if-end-if) with macros, import of dxf files into ascii format.

Extra Information

Machine equipment includes: Jet Cad control software. 90 m3/h vacuum pump. Centralized extraction point. 6 "IMC" beams. 6 vacuum cups measuring 80x155 mm. 6 vacuum cups measuring 55x155 mm.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing